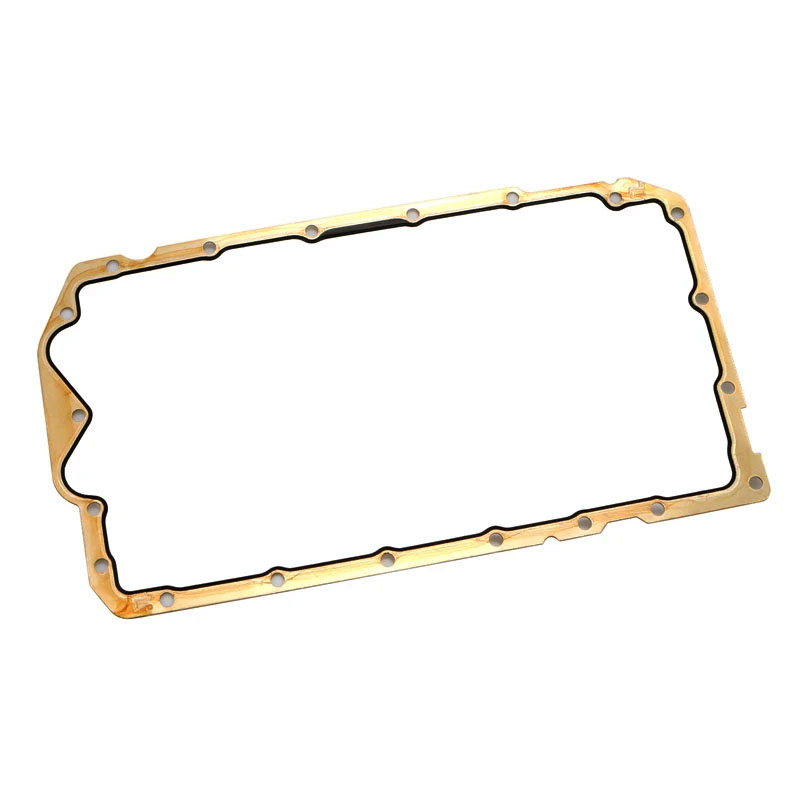

o ring flange seal

The O-Ring Flange Seal A Comprehensive Overview

The O-ring flange seal is an essential component in various engineering and industrial applications, known for its reliability and effectiveness in preventing fluid leaks. This article delves into the fundamentals of O-ring flange seals, their construction, application areas, benefits, and considerations for optimal performance.

Understanding O-Ring Flange Seals

An O-ring flange seal is a type of gasket that utilizes a circular elastomeric ring—commonly known as an O-ring—fitted into a groove on the flange of two mating parts. When these flanges are bolted together, the O-ring is compressed, forming a tight seal that prevents the escape of fluids and gases. This sealing mechanism is crucial in applications involving high pressure or extreme temperatures, where traditional gaskets may fail.

Construction and Materials

The effectiveness of an O-ring flange seal largely depends on its construction and the materials used. O-rings can be manufactured from a variety of materials, including rubber, silicone, fluorocarbon, and even metal, depending on the application's specific requirements. Common elastomers used for O-rings are

1. Nitrile (Buna-N) Offers good resistance to petroleum-based fluids and is commonly used in hydraulic and pneumatic systems. 2. Viton (Fluorocarbon) Known for its excellent chemical resistance and ability to withstand high temperatures, making it suitable for harsh environments. 3. Silicone Flexible and capable of withstanding extreme temperatures but has limitations regarding mechanical strength and wear resistance.

The flange’s design, including the groove dimensions, also plays a critical role in the sealing effectiveness. Proper engineering ensures that the O-ring is adequately compressed without being over-stressed, which could lead to premature failure.

Applications

O-ring flange seals are widely used across various industries

o ring flange seal

- Oil and Gas In drilling and refining operations, the need for robust sealing systems is paramount to avoid leaks that could have catastrophic consequences. - Automotive O-ring flange seals are common in engine assemblies, fuel systems, and cooling systems where fluid containment is crucial. - Aerospace The aerospace industry utilizes O-ring seals in fuel systems and hydraulic systems, relying on their reliability in critical applications. - Manufacturing Equipment that uses pneumatic and hydraulic systems often incorporates O-ring seals to maintain pressure and prevent leakage.

Advantages of O-Ring Flange Seals

The popularity of O-ring flange seals stems from their numerous advantages

1. Versatility O-rings can be designed for various applications, accommodating different temperatures, pressures, and media. 2. Cost-Effectiveness Compared to other sealing solutions, O-rings are relatively inexpensive and easy to replace or maintain. 3. Ease of Installation O-ring seals are straightforward to install, often requiring minimal tools or specialized skills. 4. Space Efficiency Their compact design allows for more efficient use of space in machinery and assembly.

Considerations for Optimal Performance

While O-ring flange seals are advantageous, certain factors need careful consideration for optimal performance

1. Material Selection Choosing the right material is crucial. A mismatch between the O-ring material and the media it will contact can lead to rapid degradation. 2. Compression Over-compressing the O-ring can lead to damage, while insufficient compression might result in leaks. Following recommended specifications for compression can enhance the seal's longevity. 3. Surface Finish The surfaces of the flanges need to be smooth and free from imperfections to prevent extrusions that could compromise the seal.

Conclusion

In summary, O-ring flange seals are a fundamental component in ensuring the integrity of fluid and gas systems across various industries. Their versatility, cost-effectiveness, and ease of installation make them a preferred choice for engineers and designers alike. However, careful consideration of materials, installation practices, and seal specifications is essential to maximize their performance and lifespan. As technology advances, the continued innovation in materials and design will likely enhance the capabilities of O-ring flange seals, further solidifying their importance in modern engineering.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories