Understanding the Functionality and Applications of O-Ring Face Seals

Understanding O-Ring Face Seals A Comprehensive Overview

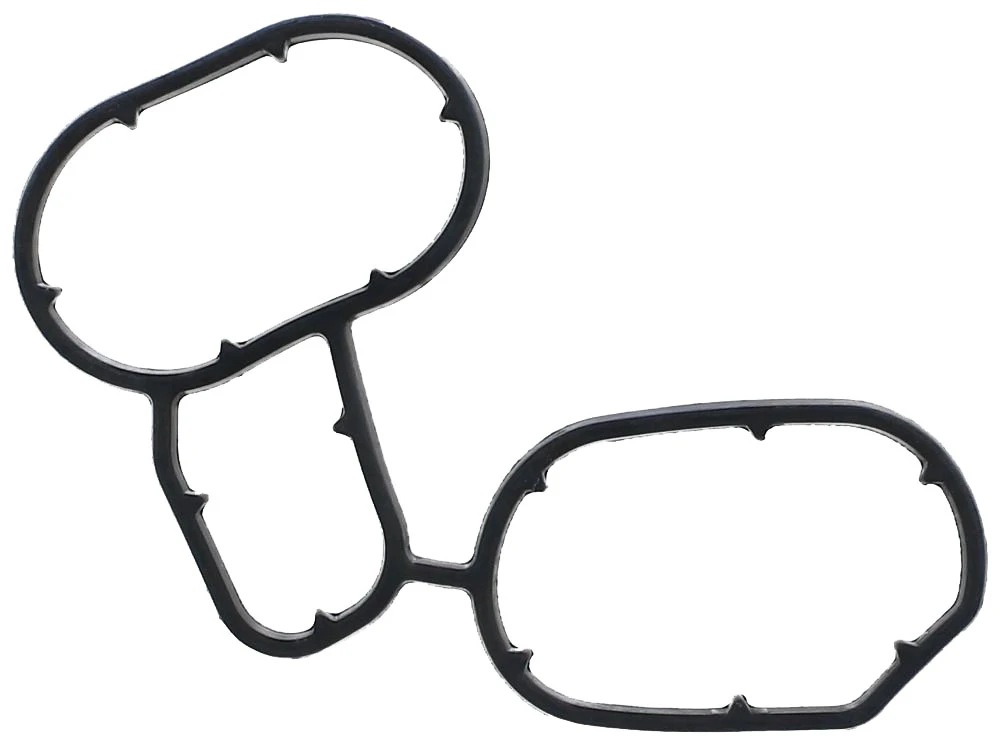

O-ring face seals are crucial components widely used in various industries, from aerospace to automotive, pharmaceuticals, and more. They are designed to provide reliable sealing solutions for rotating and stationary applications, ensuring that fluids remain contained and preventing leakage under demanding conditions. To understand the significance of O-ring face seals, it is essential to explore their construction, working principles, benefits, and applications.

Construction of O-Ring Face Seals

An O-ring face seal consists of two primary components the O-ring itself and the face seal. The O-ring is a circular cross-section elastomeric ring that is typically made from materials such as rubber, silicone, or fluoropolymer. This ring acts as a compressible element, allowing it to adapt to various groove depths and create a tight seal between two surfaces.

The face seal is generally composed of two flat surfaces that confront each other, with the O-ring positioned in a groove on one of the surfaces. When the surfaces are brought together, the O-ring is compressed, creating a barrier that prevents the escape of fluids or gases. This design ensures a low-friction seal, providing optimal performance, especially in rotary applications.

Working Principles

The effectiveness of O-ring face seals is largely attributed to their ability to maintain a tight seal despite the presence of vibration, pressure variations, and thermal expansion. As the two surfaces are pressed together, the O-ring deforms to fill any gaps, creating a hermetic seal. The compression also generates a film of lubricant, reducing friction and wear between moving parts, which is particularly beneficial in dynamic applications where rotation or linear motion occurs.

One of the unique features of O-ring face seals is their ability to self-adjust based on changes in pressure and temperature. The elastomeric nature of the O-ring means that it can recover its original shape after compressive forces are removed, maintaining a consistent sealing performance throughout the seal's lifespan.

Benefits of O-Ring Face Seals

O-ring face seals offer an array of advantages, making them a preferred choice in many applications

1. Versatility They can be used in various environments, including high-pressure and high-temperature situations, thanks to the range of materials available for O-rings. 2. Low Friction The design minimizes friction, which is particularly beneficial for rotating components, as it reduces wear and extends the life of machinery.

o ring face seal

4. Self-Adjustment Their ability to conform to irregularities in surface finishes ensures a consistent seal, despite fluctuations in operational conditions.

5. Cost-Effective Given their durability and reliability, O-ring face seals can offer long-term savings, reducing the need for frequent replacements and maintenance.

Applications

O-ring face seals find applications in numerous sectors

- Automotive Industry Used in engines, transmissions, and fuel systems where sealing against fluids is critical. - Aerospace In aircraft systems, they are essential for ensuring airtight seals in fuel lines and hydraulic systems.

- Food and Beverage In food processing equipment, they provide sanitary sealing solutions while conforming to regulatory standards.

- Pharmaceuticals Ensuring the integrity of sterile environments in drug manufacturing processes, thus maintaining safety and efficacy.

- Hydraulics Preventing fluid leaks in hydraulic cylinders and valves, contributing to the efficiency and safety of heavy machinery.

In summary, O-ring face seals are vital components that combine simplicity with efficiency. Their versatility, reliability, and ease of use make them indispensable in a variety of industries. As technology continues to evolve, so too will the materials and designs of O-ring face seals, paving the way for even more innovative sealing solutions to meet the challenges of modern engineering. Understanding their functionality and application is crucial for any professional involved in design, manufacturing, or maintenance within the relevant industries.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories