Understanding O-Ring Cord Applications and Benefits in Various Industries

The Versatility of O-Ring Cords in Modern Applications

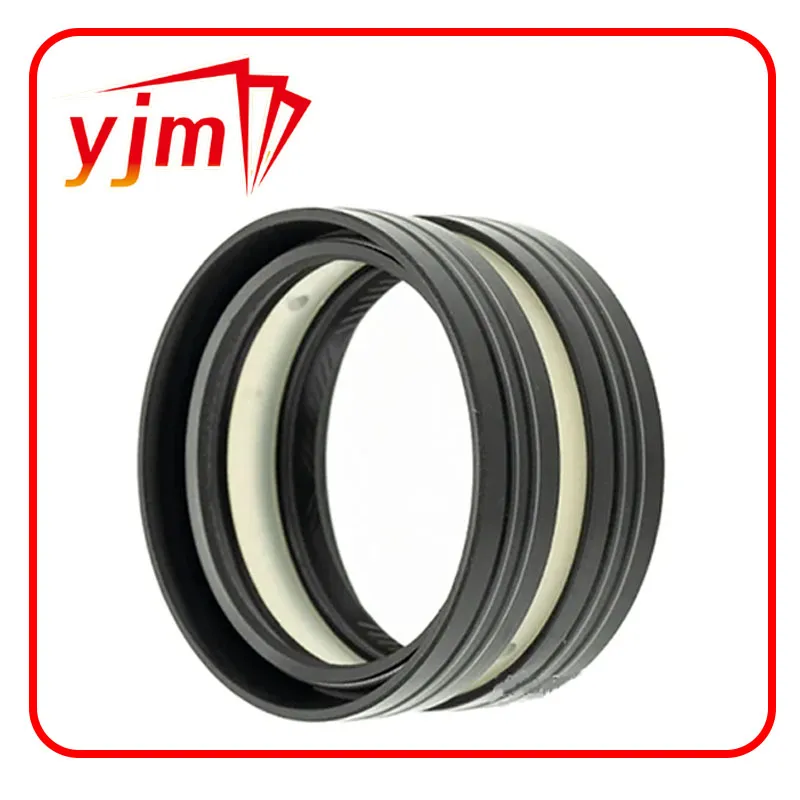

O-ring cords, often made from rubber or silicone materials, are flexible, circular lengths of cord that serve multiple purposes in various industries. These cords come in various diameters and can be customized to meet specific requirements, making them an essential component in numerous applications. Their versatility is underscored by their use in everything from automotive and aerospace to household products and industrial machinery.

The Versatility of O-Ring Cords in Modern Applications

In the aerospace industry, the reliability of O-ring seals is crucial. High-performance O-ring cords must endure extreme temperatures and pressures while maintaining their sealing capabilities. Used in critical systems such as fuel lines, hydraulic systems, and environmental control systems, these O-ring cords prevent leaks and ensure the safety and functionality of aircraft. Engineers and designers often rely on the consistent performance characteristics of O-ring cords to meet the stringent regulations and safety standards of aviation.

o ring cord

Additionally, O-ring cords are prevalent in the manufacturing of household appliances. From washing machines to dishwashers, these versatile cords can be found in gaskets and seals that keep water contained, prevent leaks, and ensure the proper functioning of various parts. Their ability to withstand exposure to water and detergents makes them an ideal choice for these applications. Moreover, the ease of customization allows manufacturers to create specific O-ring designs that accommodate the unique needs of their products.

The industrial sector also benefits greatly from O-ring cords. They are used in hydraulic systems, pneumatic applications, and various machinery where sealing is critical. O-ring cords can handle high-pressure fluids, ensuring that machinery operates smoothly and efficiently. This reliability reduces downtime and maintenance costs, making O-ring cords a practical choice for manufacturers seeking to enhance productivity.

In recent years, advancements in material science have led to the development of specialized O-ring cords that cater to unique challenges. There are O-ring cords specifically designed for extreme temperatures, chemical resistance, and enhanced wear properties. For instance, fluorocarbon O-rings offer superior resistance to aggressive chemicals, making them invaluable in the chemical processing industry. Similarly, high-temperature O-rings are engineered to perform flawlessly in environments where traditional materials might fail.

In summary, O-ring cords are integral to numerous applications across various industries due to their sealing capabilities, flexibility, and durability. From automotive engines to aerospace and industrial manufacturing, their importance cannot be overstated. With ongoing advancements in materials and technology, the future of O-ring cords looks bright, promising even more innovative applications that will further enhance efficiency and safety across sectors. As industries continue to evolve, the versatility and reliability of O-ring cords will undoubtedly play a pivotal role in shaping the future of engineering and manufacturing.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories