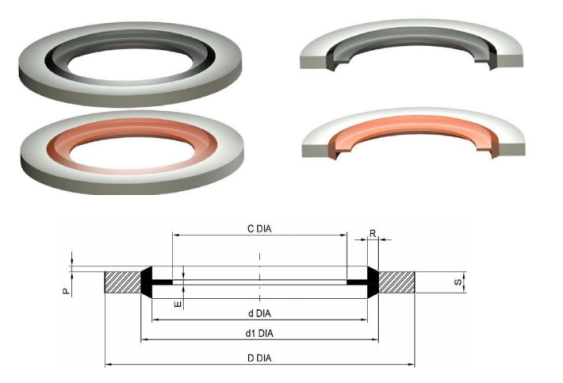

flat metal ring gasket

From an authoritative standpoint, adherence to industry standards like ISO 3601 for O ring dimensions and AS568 for usage is non-negotiable. These standards guarantee that the components meet rigorous quality and performance criteria. Consulting these guidelines is indispensable for engineers seeking to ensure compliance and optimal performance in their systems. Trustworthiness is cemented not just by selecting high-quality products but also by the supplier’s reputation. Collaborating with manufacturers known for a robust quality control process assures that the O rings and backup rings will perform as needed under specified conditions. Buyers are advised to request documentation of compliance and material certifications, a practice that underscores a commitment to reliability and safety. For businesses looking to optimize their search engine presence regarding O rings and backup rings, it is crucial to integrate relevant keywords strategically while providing valuable technical insights. Content that educates potential customers on the practical applications and advantages of using these components will inherently boost engagement metrics. In summation, O rings and backup rings form an indispensable alliance in mechanical sealing solutions. They represent an intersection of simplicity and engineering prowess, crucial for maintaining the integrity of sophisticated machinery. By focusing on genuine experience, technical expertise, and a commitment to authoritative sourcing and reliability, businesses can effectively communicate the vital role these components play, while enhancing their SEO strategy in a way that is both insightful and valuable.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories