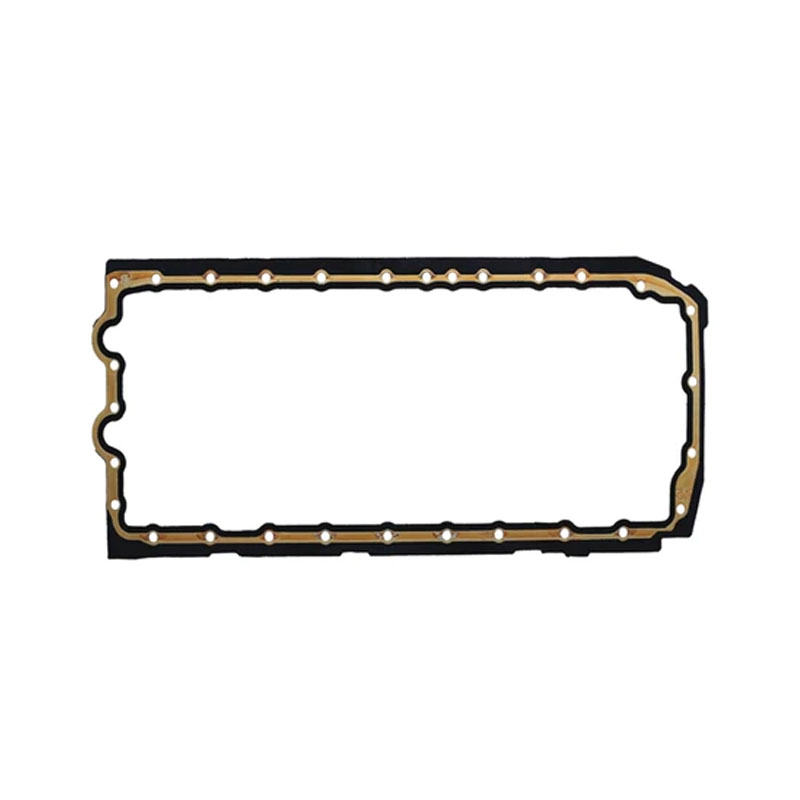

o ring backup ring

Understanding O-Ring Backup Rings A Comprehensive Guide

When it comes to sealing technologies, O-rings are among the most widely used components in various industries. They serve critical functions by providing a reliable seal to prevent leakage in numerous applications, from hydraulics to automotive systems. But to enhance the reliability and lifespan of O-rings, engineers often employ backup rings. This article delves into the importance of O-ring backup rings, how they work, and the benefits they offer.

What are O-Ring Backup Rings?

O-ring backup rings are mechanical devices designed to support O-rings in high-pressure applications. Made from materials such as polyurethane, PTFE, or other durable compounds, backup rings enable the O-rings to maintain their shape and sealing capabilities under various conditions. They are strategically placed along the inside or outside of the O-ring groove, acting as a reinforcement that prevents the O-ring from extruding or deforming during operation.

How Do Backup Rings Work?

When an O-ring is subjected to pressure, it can experience forces that may cause it to extrude out of its groove — especially in dynamic applications where there is movement. A backup ring serves as a solid barrier that restricts this extrusion. By providing additional support, backup rings ensure that the O-ring maintains its proper sealing function even under extreme pressure or fluctuating operating conditions.

There are two primary types of backup rings static backup rings and dynamic backup rings. Static backup rings are used in applications where the parts do not move relative to each other, while dynamic backup rings are utilized in applications with moving parts, ensuring the O-ring remains sealed during operation.

o ring backup ring

Benefits of Using O-Ring Backup Rings

1. Enhanced Reliability The primary advantage of using backup rings is improved sealing reliability. By preventing O-ring extrusion, backup rings significantly reduce the risk of leaks, which can lead to costly failures or safety hazards.

2. Increased Longevity O-rings can wear out due to exposure to high pressures and temperatures. With the added support of backup rings, the lifespan of O-rings is extended, saving both time and money in maintenance and replacements.

3. Versatility Backup rings are available in various sizes and materials, making them suitable for a wide range of applications, including those with extreme temperatures or pressures. This versatility allows for more design freedom and customization based on specific operational needs.

4. Cost-Effective Solution While there may be additional costs associated with integrating backup rings into a sealing solution, the reduction in maintenance and replacement costs typically justifies the investment. The long-term savings outweigh the initial expenditure, making backup rings a cost-effective choice.

Conclusion

In conclusion, O-ring backup rings play a crucial role in enhancing the performance and reliability of sealing solutions across various industries. By preventing extrusion and promoting longevity, backup rings ensure that O-rings function effectively under demanding conditions. As technology continues to advance, the importance of backup rings will only increase, solidifying their place in modern engineering and design. Understanding their role can help in selecting the most appropriate sealing solutions for specific applications, ultimately leading to safer and more efficient operations.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories