Exploring O-Ring and Backup Ring Functionality in Sealing Applications

The Importance of O-Rings and Backup Rings in Sealing Technologies

In various industrial applications, effective sealing solutions are vital for ensuring operational efficiency, safety, and longevity of equipment. Among the plethora of sealing devices available, O-rings and backup rings hold a crucial place. They serve as fundamental components in creating reliable seals, preventing leaks of fluids and gases, and protecting the integrity of machinery. This article will explore the significance, materials, applications, and advantages of O-rings and backup rings, highlighting their essential roles in sealing technologies.

Understanding O-Rings

An O-ring is a circular, doughnut-shaped elastomeric sealing element, characterized by its cross-sectional circular shape. The simplicity of its design is one of the reasons for its widespread use. O-rings function by being compressed between two mating surfaces. This compression creates a sealing force that fills the gap to prevent the escape of fluids or gases. O-rings are highly versatile and can be found in a range of sizes, materials, and hardness ratings, allowing them to be tailored for various applications.

The Role of Backup Rings

Backup rings, on the other hand, are used in conjunction with O-rings in high-pressure applications or where there is significant movement. These rings are typically made from harder materials than O-rings and are designed to prevent the O-ring from extruding or being displaced from its sealing groove, particularly in dynamic sealing situations. By providing spatial support, backup rings enhance the O-ring's performance and lifespan, particularly under extreme conditions.

Material Selection

The performance of O-rings and backup rings is heavily dependent on the materials used in their construction

. Common materials for O-rings include- Nitrile Rubber (NBR) Ideal for applications involving oils and fuels, NBR is resistant to compression set and has good wear resistance. - Fluorocarbon (FKM) Known for its exceptional chemical resistance, FKM is used in environments exposed to aggressive chemicals and high temperatures.

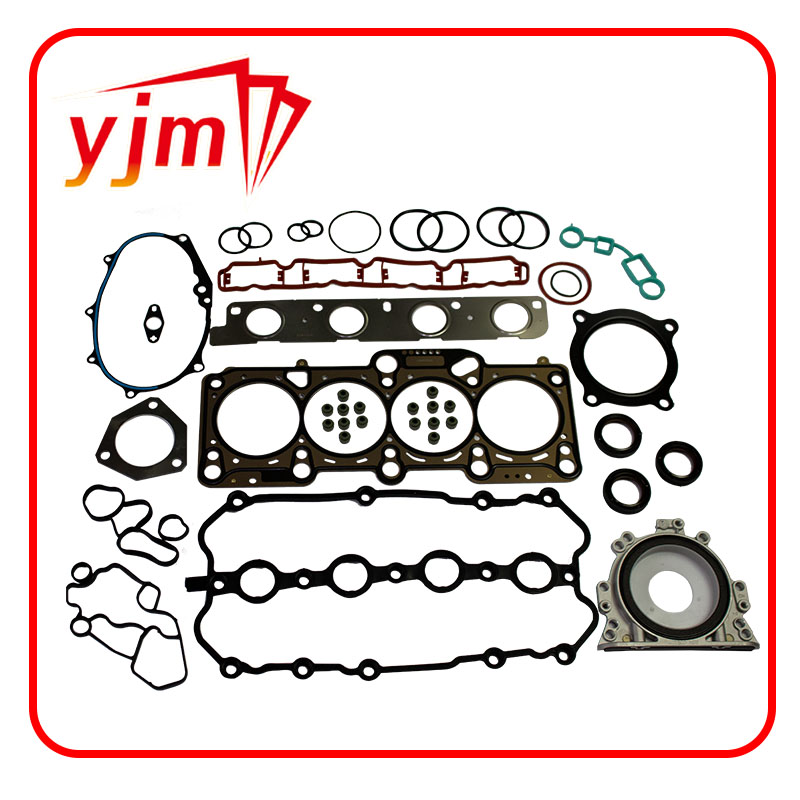

o ring and backup ring

- Silicone With excellent temperature tolerance and flexibility, silicone is used where extreme temperatures are prevalent.

- EPDM (Ethylene Propylene Diene Monomer) This material is particularly suitable for applications involving water and steam, resisting heat and oxidation.

Backup rings are often made from materials like PTFE (Polytetrafluoroethylene), which provide excellent thermal stability and chemical resistance, ensuring they can withstand harsh operating environments without degrading.

Applications in Industries

The use of O-rings and backup rings spans across numerous industries, including automotive, aerospace, oil and gas, pharmaceuticals, and food processing. In the automotive sector, they are crucial for sealing engines and transmission components, while in aerospace, they help maintain the integrity of fuel systems and hydraulic components. The oil and gas industry relies on these rings for sealing equipment exposed to extreme pressure and corrosive substances.

In the realm of pharmaceuticals, the importance of clean and reliable seals cannot be overstated. O-rings and backup rings ensure that processes remain sterile while preventing contamination of products. Similarly, in food processing, these sealing elements are designed to meet stringent safety standards, preventing leaks that could compromise product quality.

Advantages of O-Rings and Backup Rings

The benefits of utilizing O-rings and backup rings are numerous. Their simple design allows for easy installation and replacement. They also provide a cost-effective sealing solution, reducing the need for complex assemblies or machining processes. Additionally, when properly selected and installed, O-rings and backup rings can significantly extend the life of equipment by preventing leaks and protecting internal components, thereby reducing maintenance costs.

In conclusion, O-rings and backup rings are integral to contemporary sealing technologies. Their versatility, cost-effectiveness, and performance reliability make them indispensable across a wide range of applications. As industries continue to evolve and demand higher performance standards, the importance of these components will only grow, underscoring the need for ongoing innovation in materials and design to meet the challenges of the future. Whether in a manufacturing plant or a high-tech aerospace application, O-rings and backup rings are the unsung heroes that keep systems sealed and functioning optimally.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories