o ring 90mm

The Importance of O-Rings in Industry A Focus on the 90mm Variant

O-rings are one of the most ubiquitous components used across various industries, including automotive, aerospace, manufacturing, and plumbing. Among the numerous sizes available, the 90mm O-ring has gained significant importance due to its versatility and effectiveness in sealing applications. This article delves into the characteristics, uses, and advantages of 90mm O-rings, as well as their impact on industrial efficiency and safety.

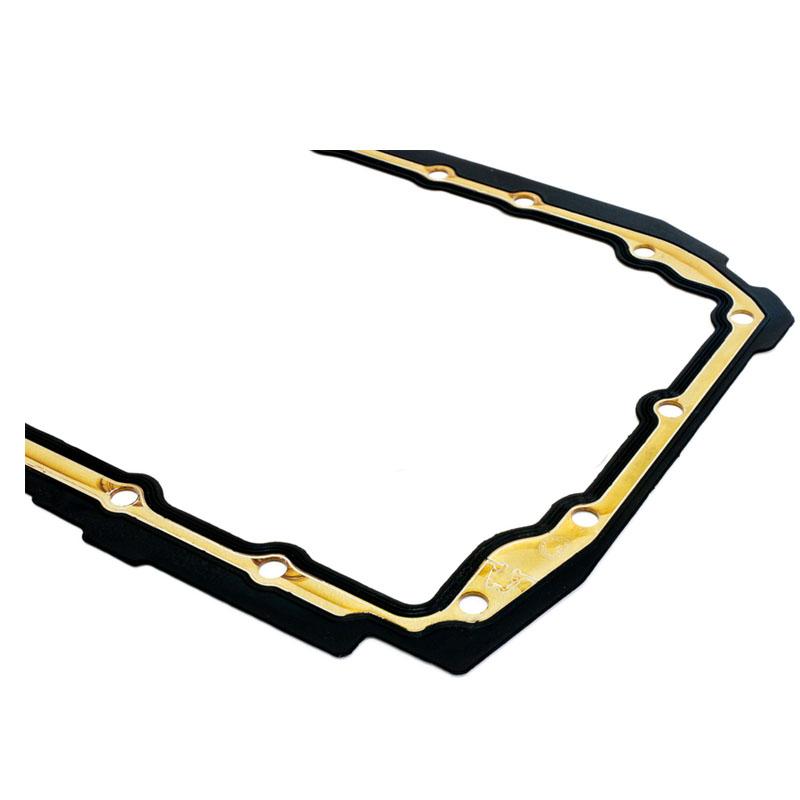

First, let’s explore what O-rings are. An O-ring is a mechanical gasket in the shape of a torus, designed to be seated in a groove and compressed during assembly between two or more parts. This design is crucial as it creates a seal that prevents the passage of fluids or gases. The efficiency of an O-ring depends largely on its material composition, size, and installation, making the right choice of O-ring critical for success.

The Importance of O-Rings in Industry A Focus on the 90mm Variant

In the automotive industry, 90mm O-rings are frequently used in various applications, such as in engines, fuel systems, and hydraulic components. For instance, they can be found in fuel tanks where a reliable seal is essential to prevent leaks that could pose safety risks. In hydraulic systems, they are critical for maintaining pressure and ensuring the smooth operation of machinery. A failure in the O-ring can lead to significant performance issues and costly repairs, emphasizing the need for selecting the right O-ring.

o ring 90mm

Moreover, the aerospace industry also relies heavily on O-rings, including the 90mm variant. Aircraft and spacecraft components must operate under extreme conditions, including significant fluctuations in temperature, pressure, and exposure to various chemicals. The integrity of O-rings in these applications is vital for safety and functionality. A well-designed O-ring ensures that seals withstand these challenges, preventing dangerous leaks or malfunctions.

One of the most significant advantages of using O-rings is their simple installation process. The compact design allows them to be easily integrated into various systems, saving time and labor costs during assembly. Additionally, O-rings can be used in both dynamic and static applications, showcasing their adaptability across different environments.

Furthermore, regular maintenance and prompt replacement of worn O-rings can greatly extend the lifespan of machinery and equipment. This proactive approach not only enhances operational efficiency but also reduces the risk of catastrophic failures and unscheduled downtimes, which can be expensive for businesses.

In conclusion, the 90mm O-ring plays a critical role in achieving effective sealing in various industrial applications. Its ideal dimensions, coupled with the choice of materials, make it a reliable component for ensuring the integrity of systems in demanding environments. As industries continue to evolve, the need for reliable and efficient sealing solutions like the 90mm O-ring will only grow, cementing its importance in modern engineering and manufacturing processes. Understanding and utilizing the capabilities of O-rings can pave the way for safer, more efficient operations across many sectors.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories