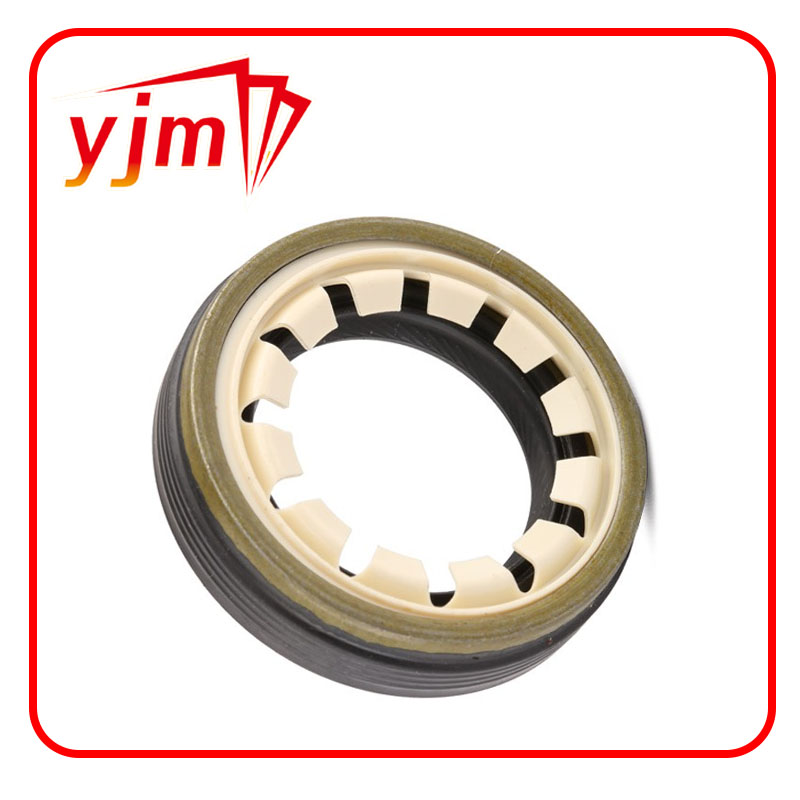

o ring 85mm

Understanding O-Rings A Focus on 85mm Models

When it comes to sealing solutions in various industries, O-rings are a vital component that ensures reliable performance. An O-ring is a simple yet effective circular sealing element, typically made from elastomeric materials like rubber, silicone, or fluoropolymer. These seals are designed to prevent the escape of fluids and gases, making them crucial in applications ranging from automotive to aerospace. This article focuses on O-rings, particularly the 85mm variant, exploring their materials, applications, and importance in engineering.

What is an O-Ring?

An O-ring is essentially a doughnut-shaped rubber seal. Its design allows it to fit snugly into a groove, compressing when assembled between two surfaces. This compression creates a tight seal, preventing leakage. The versatility of O-rings lies in their ability to withstand various pressures, temperatures, and chemical exposures, making them suitable for numerous applications.

Sizing of O-Rings The 85mm Standard

The designation of an O-ring, such as 85mm, refers to its inner diameter. An 85mm O-ring typically has a cross-section that can vary, influencing its performance characteristics. Common cross-sectional sizes for O-rings can range from 1.78mm to 3.55mm, depending on the application’s requirements. Choosing the correct size is crucial; too small may lead to insufficient sealing, while too large can cause installation challenges.

Materials Used in O-Ring Manufacturing

The choice of material for an O-ring plays a significant role in its effectiveness. Common materials include

1. Nitrile (NBR) Ideal for general-purpose applications, Nitrile O-rings offer good resistance to oils and fuels, making them popular in automotive applications.

2. Fluorocarbon (Viton) With excellent resistance to high temperatures and aggressive chemicals, Viton O-rings are preferred in aerospace and chemical processing industries.

3. Silicone Known for its high-temperature resistance and flexibility, silicone O-rings are often used in food and pharmaceutical applications.

o ring 85mm

4. EPDM Ethylene Propylene Diene Monomer O-rings are exceptional for outdoor applications and resist heat, ozone, and weathering.

Each material has its strengths and weaknesses, which must be matched to the specific application environment to ensure optimal performance.

Applications of 85mm O-Rings

O-rings, especially those at the size of 85mm, find extensive use in various applications

- Hydraulic Systems In hydraulic cylinders, 85mm O-rings help in maintaining pressure and preventing leaks, which is critical for the efficiency of machinery.

- Pneumatic Systems They are used in pneumatic tools and equipment to create airtight seals, ensuring proper functioning and comfort.

- Automotive Industry O-rings are frequently used in automotive engines, fuel systems, and air conditioning systems to prevent fluid leaks.

- Aerospace The reliability of O-rings in extreme conditions makes them indispensable in aircraft design, where safety is paramount.

Conclusion

The 85mm O-ring is a testament to the engineering marvels that simple shapes can contribute significantly to various industries. Understanding their functionality, material selection, and appropriate applications ensures that engineers and technicians can implement effective sealing solutions that meet safety and efficiency standards. As we continue to innovate and develop new technologies, the role of O-rings in creating robust and reliable systems will only become more critical.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories