o ring 150mm

Understanding the Importance of O-Rings The 150mm Case

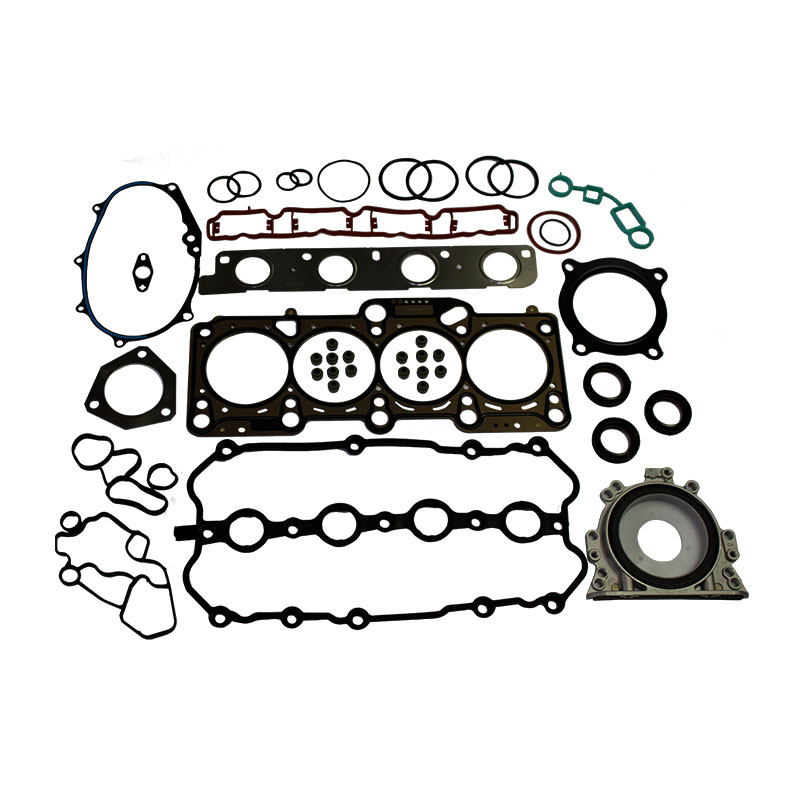

O-rings are ubiquitous components in engineering and manufacturing, playing a vital role in ensuring the efficiency and safety of various systems. When focusing on a specific size, such as the 150mm O-ring, it becomes clear how critical these seals can be across different applications, from automotive to aerospace.

What is an O-Ring?

An O-ring is a circular, donut-shaped elastomeric seal designed to create a seal at the interface between two objects. Typically made from materials such as rubber, silicone, or polyurethane, these seals are used to prevent the escape of fluids and gases. When compressed between two mating surfaces, an O-ring deforms to fill the gap, thereby creating an effective barrier against leakage.

The Significance of the 150mm Size

The 150mm O-ring represents a specific diameter that fits particular applications requiring a substantial seal. Its size makes it ideal for various industrial purposes, including hydraulic systems, pneumatic devices, and even household appliances. The larger the O-ring, the more volume it can effectively seal, allowing it to handle higher flow rates and pressures—all while maintaining durability and flexibility.

Applications of 150mm O-Rings

1. Hydraulic Systems In hydraulic machinery, 150mm O-rings are commonly used to seal hydraulic cylinders and pumps, ensuring that the hydraulic fluid does not leak under high pressure. They maintain system integrity and performance, preventing operational failures that could lead to costly downtime.

2. Pneumatic Applications Similar to hydraulic systems, pneumatic devices use compressed air to function. A 150mm O-ring can provide excellent sealing properties in pneumatic actuators and valves, reducing the risk of air leaks that could compromise efficiency.

o ring 150mm

3. Automotive Sealing In the automotive sector, components such as engine oil pumps and water pumps often feature O-rings. The 150mm size could be used in larger vehicle systems, ensuring effective sealing to prevent leakage of crucial fluids, which, in turn, contributes to the longevity and reliability of the vehicle.

4. Aerospace and Aviation In the aerospace industry, precision and reliability are paramount. O-rings play a vital role in sealing fuel systems, hydraulic controls, and pressurized cabins. A 150mm O-ring could be crucial to maintaining the integrity of systems that operate under extreme conditions, both in terms of pressure and temperature.

5. Food and Pharmaceutical Industries In environments that necessitate cleanliness and sanitary conditions, such as food processing and pharmaceuticals, O-rings are used in equipment to prevent contamination. The resistance to certain chemicals and high temperatures makes 150mm O-rings suitable for these applications, ensuring that products remain safe and uncontaminated.

Material Selection

The effectiveness of a 150mm O-ring is not just about size; the material from which it is made plays an equally important role. Selecting the right elastomer is critical for optimal performance, especially regarding temperature resistance, chemical compatibility, and mechanical durability. Common materials include

- Nitrile Rubber (NBR) Known for good resistance to oils and fuels, it's commonly used in automotive applications. - Silicone Rubber Excellent for high-temperature applications and widely used in food and medical industries. - Fluorocarbon (Viton) Offers superior resistance to high temperatures and chemical exposure, essential in rigorous industrial environments.

Conclusion

The 150mm O-ring is a powerful yet simple technology that plays a crucial role across various sectors. Its ability to create effective seals allows machinery and systems to function optimally, consequently boosting productivity and reliability. As industries continue to evolve and demands for efficiency rise, the importance of high-quality O-rings, including those sized at 150mm, will remain significant. Whether in automotive, aerospace, or manufacturing, understanding and selecting the right O-ring can make a considerable difference in performance and longevity. O-rings make the world go round, often in ways we might not appreciate until they fail. Investing in quality components is not merely a choice; it’s a necessity for operational excellence.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories