Effective Solutions for Oil Stem Seals in Automotive Applications

Understanding Oil Stem Seals Function, Importance, and Applications

Oil stem seals are critical components in various mechanical systems, particularly in engines and hydraulic systems, where they play a pivotal role in maintaining efficiency and reliability. These seals are designed to prevent oil leakage while ensuring that the hydraulic pressure needed for proper operation is sustained. Their importance cannot be overstated, particularly in applications where fluid integrity is essential for performance and safety.

Function of Oil Stem Seals

At their core, oil stem seals function as barriers that control the flow of lubricating oil in machinery. They accomplish this by forming a tight seal between moving parts, effectively preventing oil from leaking out and contaminants from entering the system. This containment is vital for the smooth operation of engines and machinery, where even a small amount of oil loss can lead to significant performance issues and accelerated wear.

The construction of oil stem seals typically involves materials that can withstand high temperatures and pressures while maintaining their flexibility and strength. Common materials include rubber compounds, thermoplastics, and sometimes metal reinforcements. These materials are chosen for their resilience and chemical resistance, ensuring that they can endure the harsh conditions often found in industrial applications and automotive environments.

Importance of Oil Stem Seals

Oil stem seals are especially critical in automotive engines, where they serve to maintain oil within the engine block and various components, such as valve stems and crankshafts. Leaks in these areas can not only lead to the loss of lubrication but also create a hazardous environment, increasing the risk of fires due to oil contact with hot surfaces. Furthermore, improper sealing can contribute to the contamination of the engine oil, leading to significant wear on engine parts and ultimately resulting in costly repairs.

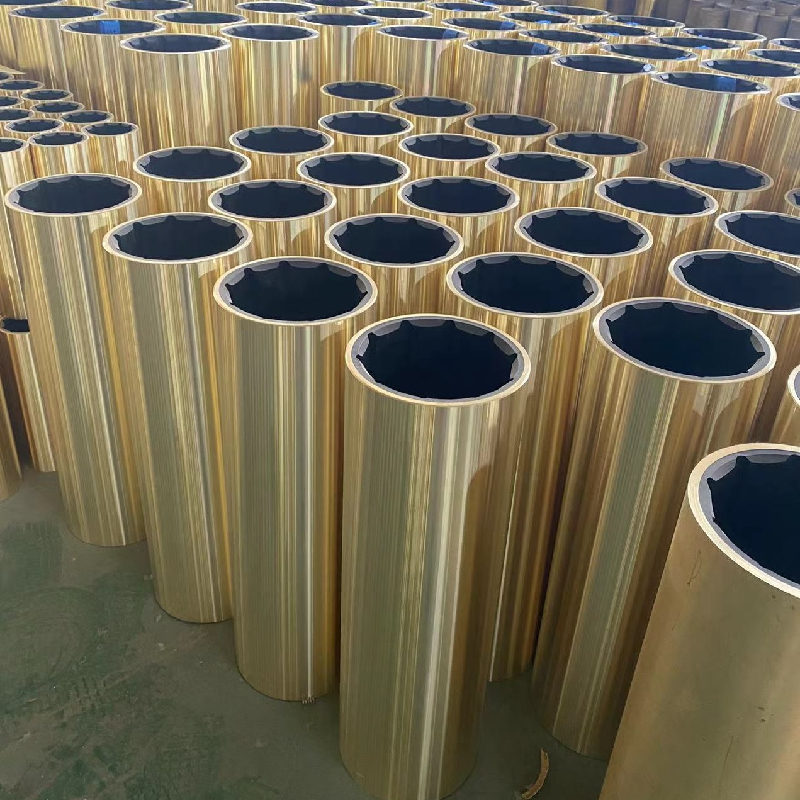

oil stem seals

Beyond automotive applications, oil stem seals are prevalent in hydraulic machinery, such as excavators and forklifts. In these systems, hydraulic fluid plays a crucial role in transferring power. Ensuring that the hydraulic fluid remains contained is essential for efficient operation; leaks can severely impair the functioning of hydraulic systems, costing time and money in maintenance and repairs.

Applications Across Industries

The versatility of oil stem seals allows them to be used in a range of industries. Aside from automotive and hydraulic applications, they are also essential in aerospace, manufacturing, and construction. In aerospace, for example, the reliability of oil seals in engine assemblies is paramount for the safety of flights. Likewise, in manufacturing processes that rely on precision machinery, oil seals help maintain optimal performance and protect expensive equipment from damage caused by oil leaks.

The development of oil stem seal technology is continuously evolving. Innovations in material science aim to improve the durability and efficiency of these seals, enhancing their performance under extreme conditions. Furthermore, advancements in design, such as the inclusion of multiple sealing lips or newly engineered geometries, help to optimize the sealing capabilities while reducing the chances of oil leakage.

Conclusion

In summary, oil stem seals are fundamental components that serve an essential function across varied industries. Their ability to prevent oil leaks and protect machinery from contamination is crucial for maintaining efficiency and preventing costly repairs. As we continue to see advancements in technology and materials, the effectiveness and reliability of oil stem seals are expected to improve, thereby supporting the ongoing demands of modern machinery and engines. Their role not only enhances operational efficiency but also contributes significantly to safety and environmental protection by minimizing potential oil spills and contamination.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories