Guidelines for Choosing the Right Oil Seal for Your Application

Understanding Oil Seal Selection A Comprehensive Guide

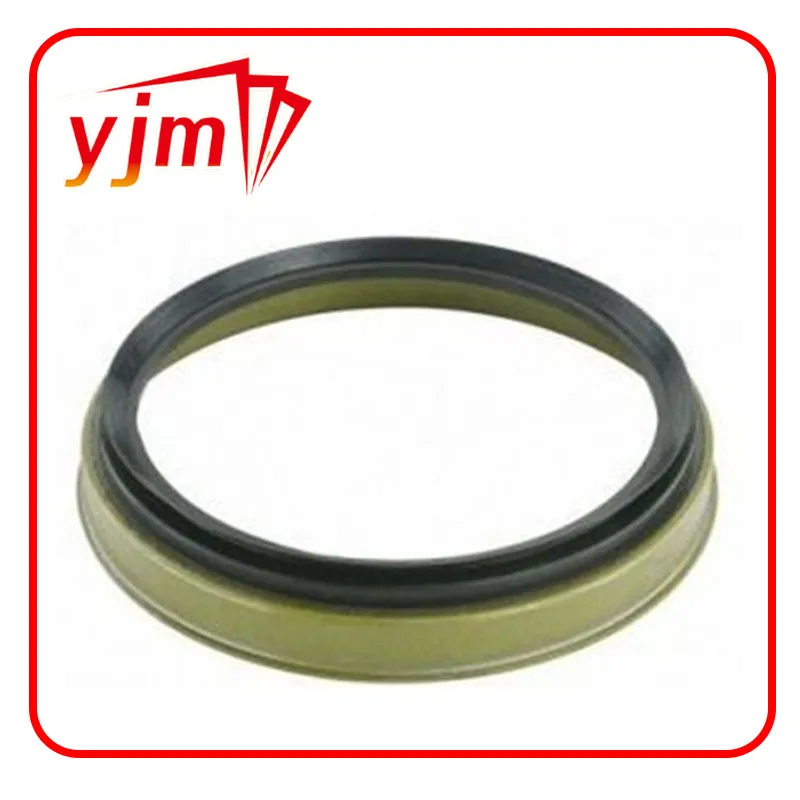

Oil seals play a crucial role in various machinery and equipment by preventing the leakage of lubricants while also keeping contaminants out. Selecting the right oil seal can significantly enhance the performance and longevity of equipment. This article aims to provide a comprehensive guide to oil seal selection, outlining key considerations that engineers and technicians should keep in mind.

1. Understanding Oil Seal Functions

Before diving into the selection process, it is important to understand the fundamental functions of oil seals. Their primary purpose is to retain lubrication within components, such as bearings and gears, while preventing external contaminants like dirt, dust, and water from entering. Additionally, oil seals minimize friction and wear between moving parts, thus enhancing operational efficiency.

2. Types of Oil Seals

Oil seals come in various types, each designed for specific applications. The most common types include

- Lip Seals These consist of a rubber or elastomeric lip that makes contact with a shaft. They are widely used due to their high sealing efficiency and ability to adapt to shaft misalignment. - Mechanical Seals Typically used in high-pressure applications, mechanical seals rely on two flat surfaces that are pressed together. These seals can provide superior sealing capabilities but are generally more complex and expensive.

- O-Rings While not a typical oil seal, O-rings are often used in conjunction with other sealing methods. They provide a reliable seal for static and dynamic applications.

Understanding the application requirements will guide the selection of the appropriate oil seal type.

3. Material Selection

The material of an oil seal is a critical factor influencing its performance. Common materials include

- Nitrile Rubber (NBR) This versatile material is widely used for oil seals due to its excellent resistance to petroleum products, aging, and moderate heat conditions

.oil seal selection

- Fluoroelastomers (FKM) Offering superior heat and chemical resistance, FKM is suitable for applications involving aggressive chemicals and high temperatures.

- Polyurethane Known for its wear resistance and durability, polyurethane is an excellent choice for applications subject to harsh conditions.

When selecting the seal material, consider factors such as operating temperature, chemical compatibility, and the type of fluid being sealed.

4. Size and Fit

The size of the oil seal is vital to its effectiveness. A proper fit ensures that the seal performs its function without leakage. To select the right size, you need to know the shaft diameter and housing bore dimensions. It is also essential to consider the tolerances, as improper sizing can lead to premature wear or seal failure.

5. Operating Conditions

Understanding the operating conditions is paramount for successful oil seal selection. Factors such as temperature fluctuations, pressure levels, and rotational speed can all impact the performance of the seal. When choosing an oil seal, it’s essential to evaluate these conditions to ensure the material and design are suited for the intended application.

6. Manufacturer Specifications

Always refer to the manufacturer's specifications when selecting oil seals. These specifications provide detailed information about the seal's material properties, operational limits, and suitability for specific applications. Following these guidelines will help in achieving optimal performance and reliability.

7. Conclusion

Selecting the right oil seal is essential for maintaining the efficiency and longevity of machinery. By considering the type of seal, material selection, proper sizing, and operating conditions, engineers can make informed decisions that meet application demands. Investing time in the oil seal selection process can prevent costly downtime and extend the life of equipment. Whether you are working on a simple task or a complex machinery project, understanding these principles will help ensure the success of your sealing applications.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories