Oil Seals and Rubber Products for Optimal Performance and Durability in Various Applications

The Importance of Oil Seals and Rubber Products in Modern Industries

Oil seals and rubber products play a critical role in countless applications across various industries. From automotive engineering to manufacturing and even household items, these components ensure smooth operation, prevent contamination, and enhance the overall performance of machinery and devices. This article delves into the significance of oil seals and rubber products, their applications, and their benefits.

What Are Oil Seals?

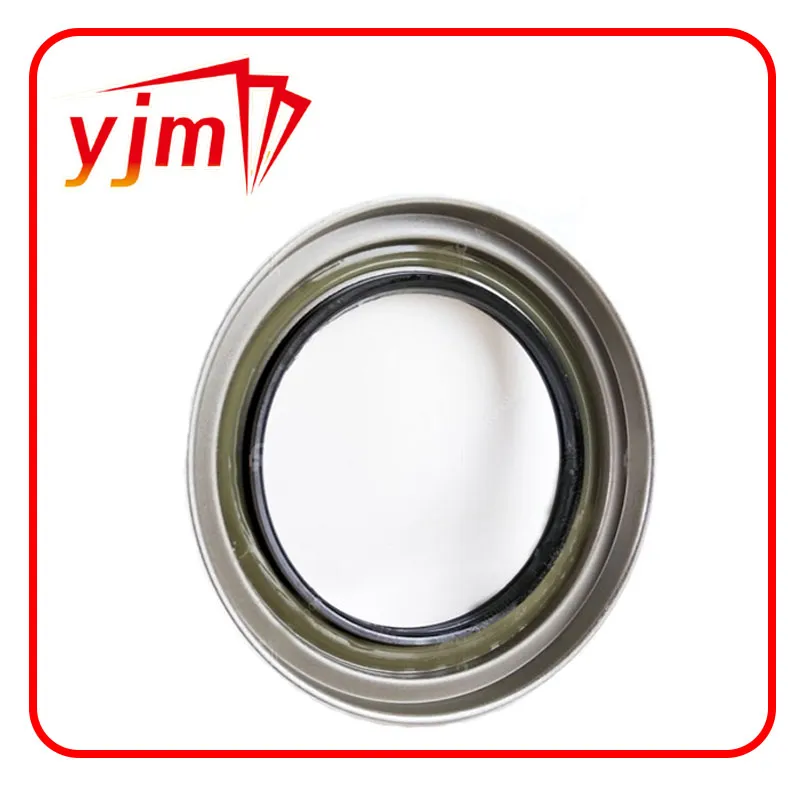

Oil seals, also known as shaft seals, are mechanical components designed to retain lubricating oil while preventing the ingress of dirt, dust, and other contaminants. They create a seal between moving and stationary parts in machinery, such as engines and gearboxes, to ensure efficient operation. Made primarily from rubber or thermoplastic materials, oil seals come in various shapes and sizes to suit different applications.

The structure of an oil seal typically includes a sealing lip, which makes contact with the shaft, and a casing that fits snugly in the housing. The lip is responsible for maintaining the seal, and its design can vary depending on the intended purpose. For example, lip geometry, hardness, and surface finish are all tailored to meet specific performance requirements.

Applications of Oil Seals

Oil seals are used in a vast array of applications, including

1. Automotive Industry Oil seals are essential in vehicles, sealing critical areas in engines, transmissions, and differentials. They help maintain proper lubrication, enhance fuel efficiency, and extend the lifespan of components.

2. Industrial Machinery In manufacturing settings, oil seals are used in pumps, compressors, and conveyor systems to prevent leaks and contamination. This is crucial for maintaining operational efficiency and reducing maintenance costs.

3. Aerospace Oil seals in aerospace applications must withstand extreme conditions, including high temperatures and pressures. They are critical in ensuring the reliability of aircraft systems.

The Role of Rubber Products

oil seal & rubber products

Rubber products, including gaskets, O-rings, and bushings, complement the functions of oil seals by providing additional sealing and cushioning capabilities. Rubber offers excellent elasticity, resilience, and resistance to wear, making it an ideal material for many industrial applications.

Rubber products serve various purposes in different industries

- Gaskets Used to create a tight seal between two surfaces, ensuring that no fluids escape or contaminants enter. - O-Rings Circular sealing devices that prevent the passage of fluids and gases in dynamic or static applications. - Bushings Provide cushioning and support between moving parts, absorbing vibrations and reducing friction.

Benefits of Using Oil Seals and Rubber Products

The advantages of integrating high-quality oil seals and rubber products into industrial systems cannot be overstated

1. Enhanced Performance These components improve the efficiency of machinery by minimizing leaks and reducing friction, leading to better energy use.

2. Increased Longevity By protecting against contamination and lubricating effectively, oil seals and rubber products extend the lifespan of equipment and reduce the need for costly repairs.

3. Cost-Effectiveness Investing in quality seals and rubber products can result in significant savings on maintenance and downtime, ultimately benefiting the bottom line.

4. Environmental Protection By preventing leaks and minimizing waste, oil seals and rubber products contribute to a cleaner environment and compliance with regulations.

Conclusion

In summary, oil seals and rubber products are integral components in modern machinery and applications. Their ability to maintain efficiency, protect against contamination, and enhance longevity makes them essential in various industries. As technology continues to evolve, the development of advanced oil seals and rubber products will undoubtedly play a pivotal role in driving innovation and improving performance across sectors. Emphasizing quality in these components is not just an option; it's a necessity for achieving optimal results in any industrial operation.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories