oil seal power steering

Understanding Oil Seal Power Steering An In-Depth Overview

In the world of automotive engineering, power steering is a crucial system that enhances the driver’s ability to maneuver a vehicle with ease. One critical component that often goes unnoticed but plays a significant role in the functionality of power steering systems is the oil seal. This article delves into the importance of oil seals in power steering systems, their construction, and maintenance.

What is Power Steering?

Power steering is a system that helps reduce the amount of effort needed to steer a vehicle. It uses hydraulic or electric actuators to assist the driver in turning the steering wheel. Most modern vehicles rely on hydraulic power steering, which utilizes a pump to direct pressurized fluid to the steering gear, reducing the physical effort required to turn the steering wheel.

The Role of Oil Seals

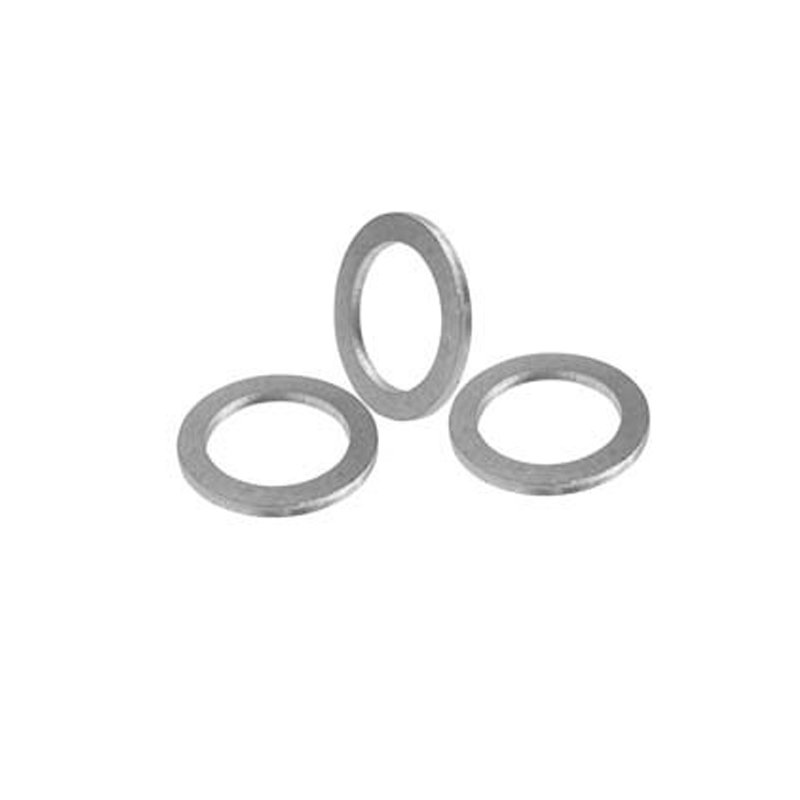

Oil seals, sometimes referred to as shaft seals or lip seals, are vital for maintaining the integrity and performance of power steering systems. These seals are designed to prevent the leakage of hydraulic fluid from the steering gear and other components, ensuring that the system operates smoothly and efficiently. They also protect the internal parts of the steering system from dirt, moisture, and other contaminants that could lead to wear and tear.

Construction of Oil Seals

Oil seals are typically made from materials like rubber, silicone, or polyurethane. These materials are chosen for their ability to withstand variations in temperature and pressure while maintaining a good seal. The design of an oil seal usually features a lip that makes contact with the shaft, creating a barrier that retains the hydraulic fluid within the system. The effectiveness of the seal is critical, as any compromise can lead to fluid leakage, resulting in loss of pressure and, subsequently, steering assist.

Signs of Worn Oil Seals

oil seal power steering

Over time, oil seals can wear out due to factors such as age, heat, and exposure to harsh environmental conditions. Drivers should be aware of several warning signs that indicate a potentially failing oil seal in their power steering system. These include

1. Fluid Leaks Puddles of hydraulic fluid under the vehicle can be a clear indication that there’s a leak caused by a worn seal. 2. Steering Difficulty If the steering wheel becomes hard to turn or feels less responsive, it may mean that the hydraulic system is losing pressure due to a leaking oil seal.

3. Noisy Steering System A whining or groaning noise when turning the wheel could suggest that the power steering pump is struggling due to insufficient fluid, which in turn may be caused by a faulty seal.

Maintenance and Replacement

To avoid issues related to oil seal failure, regular maintenance of the power steering system is essential. This includes inspecting the seals for signs of wear and replacing them when necessary. A general rule of thumb is to check the seals every time the power steering fluid is changed, which is typically every 30,000 to 50,000 miles, depending on the vehicle manufacturer’s recommendations.

When replacing worn oil seals, it's crucial to choose high-quality components to ensure long-lasting performance. Installation should be handled by professionals, as improper placement can lead to premature seal failure.

Conclusion

Oil seals play an indispensable role in the functioning of power steering systems, ensuring that hydraulic fluid remains confined to its designated pathways while preventing external contaminants from entering. Recognizing the signs of worn seals and performing regular maintenance can not only prolong the life of the power steering system but also enhance overall vehicle performance and safety. In essence, paying attention to these seemingly small components can save drivers significant time and money in repairs down the road.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories