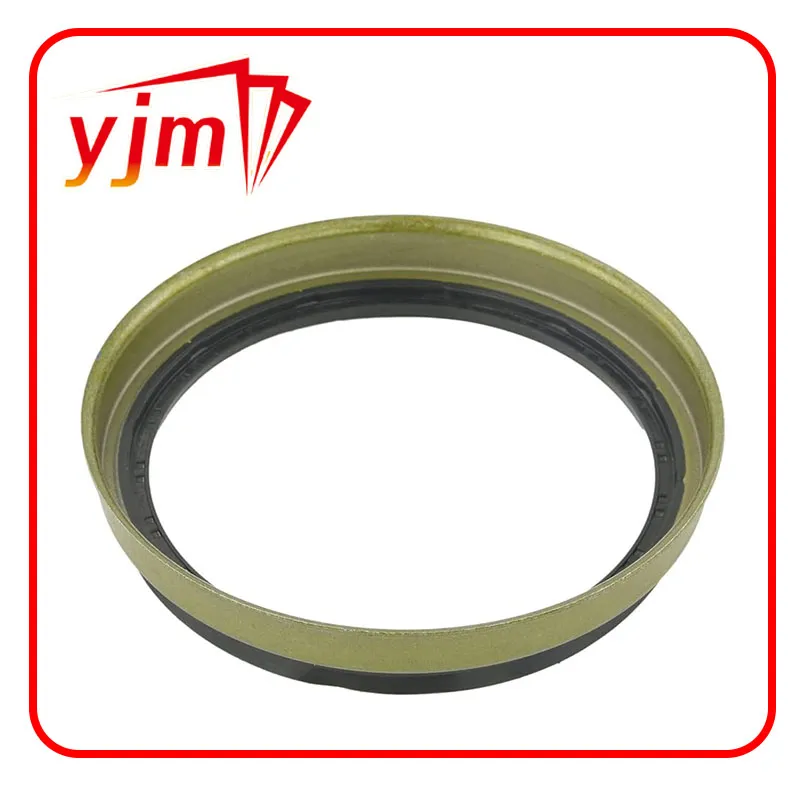

Engine Crankshaft Oil Seal 9031683001

Authoritativeness among Chinese oil seal manufacturers is reinforced by adherence to international standards. Companies often possess ISO certifications and comply with regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). Such compliance not only validates their manufacturing processes but also builds trust with global clientele, ensuring that the products meet stringent international quality standards. Trustworthiness, perhaps the most critical pillar, is achieved through transparency and reliable customer service. Reputable manufacturers provide detailed product specifications, transparent pricing, and robust after-sales support. A customer-centric approach ensures that clients receive timely responses to inquiries and technical assistance, fostering long-lasting business relationships built on mutual respect and reliability. In the domain of oil seal production, Chinese manufacturers are not merely suppliers; they are partners in engineering excellence. Through continuous improvement and customer collaboration, they offer innovative solutions that cater to a global market, emphasizing sustainability and efficiency. For businesses considering importing oil seals from China, engaging with manufacturers who exemplify experience, expertise, authoritativeness, and trustworthiness is indispensable. Evaluating manufacturers on these parameters ensures that you embark on partnerships that elevate your operational capabilities and reinforce your competitive advantage, while accessing some of the most advanced and reliable oil seal solutions available today.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories