oil seal manufacturers

Understanding Oil Seal Manufacturers Their Role and Importance in Industrial Applications

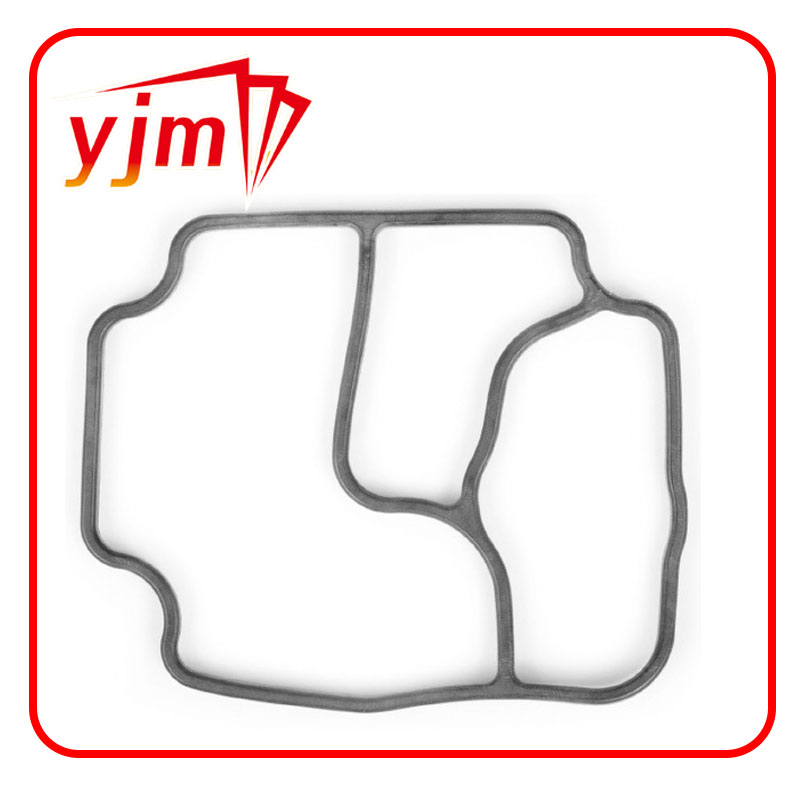

Oil seals, also known as oil seals or rotary shaft seals, are vital components in various machinery and equipment, designed to prevent the leakage of lubricants from engines, gearboxes, and other assemblies. The role of oil seal manufacturers is crucial in ensuring the reliability and longevity of these seals, as they provide the essential materials and engineering expertise necessary for effective sealing solutions. This article delves into the various aspects of oil seal manufacturers, including their importance, production processes, and the criteria for selecting a reliable supplier.

The Importance of Oil Seals

Oil seals serve two primary functions. Firstly, they prevent lubricant escape, which is crucial for maintaining the proper lubrication of moving parts within machinery. Secondly, they protect the internal components from contaminants such as dust, dirt, and moisture, which can significantly impact the performance and longevity of the equipment. The failure of oil seals can lead to costly repairs and downtimes, making the role of manufacturers in producing high-quality seals all the more critical.

Manufacturing Processes

The manufacturing of oil seals involves several key stages, starting from design and material selection to production and quality control. Typically, oil seals are designed to fit specific machinery requirements and operational conditions, including temperature, pressure, and the type of lubricants used.

1. Material Selection The materials used in oil seals are crucial for their performance. Common materials include rubber, silicone, and thermoplastic elastomers. Each material offers different properties, such as resistance to temperature extremes, chemical exposures, and mechanical stresses.

2. Design Oil seal manufacturers utilize advanced software for the design process, enabling them to create seals that conform precisely to the specifications of the equipment. CAD (Computer-Aided Design) tools help in visualizing dimensions and features, ensuring a precise fit.

3. Production After finalizing the design, manufacturers begin the production process, which can involve techniques like extrusion, molding, or machining. Ensuring uniformity in production is essential to guarantee that each seal meets industry standards.

4. Quality Control Rigorous testing and quality control measures are implemented at various stages of production. This often includes dimension checks, material hardness assessments, and tests for resistance to various environmental factors. Ensuring that each oil seal meets high standards is critical for the performance and reliability of the final products.

oil seal manufacturers

Choosing a Reliable Oil Seal Manufacturer

When it comes to selecting an oil seal manufacturer, several factors should be taken into consideration

1. Experience and Expertise Look for manufacturers with a proven track record in the industry. Their experience can provide valuable insights into material selection and design considerations.

2. Quality Certifications Reputable manufacturers often hold industry-recognized quality certifications, such as ISO 9001. These certifications signal their commitment to delivering high-quality products.

3. Customization Capabilities Depending on specific application needs, the ability to customize oil seals is essential. A good manufacturer should offer tailored solutions that meet unique requirements.

4. Customer Support and Service The level of customer support provided can significantly affect your overall experience. A responsive company that offers technical support and assistance can make all the difference when addressing any challenges that may arise.

5. Reviews and References Researching customer reviews and seeking references can help in assessing the reliability and reputation of the manufacturer. First-hand accounts from other businesses can provide insights into their quality and service levels.

Conclusion

Oil seal manufacturers play a fundamental role in ensuring that machinery operates efficiently and reliably. Their focus on quality, precision, and innovation directly impacts the performance of various applications across multiple industries. By understanding the manufacturing process, the importance of high-quality seals, and the criteria for selecting a manufacturer, businesses can make informed decisions that foster equipment longevity and performance excellence. As industries continue to evolve, the demand for superior oil seals will remain pivotal, driving manufacturers to innovate and enhance their offerings continuously.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories