oil seal manufacturers

Oil seal manufacturers play a pivotal role in the machinery and automotive industries, offering specialized solutions that ensure the proper functioning of numerous systems. Understanding the significance of oil seals and selecting a reliable manufacturer can dramatically enhance equipment performance, reliability, and longevity.

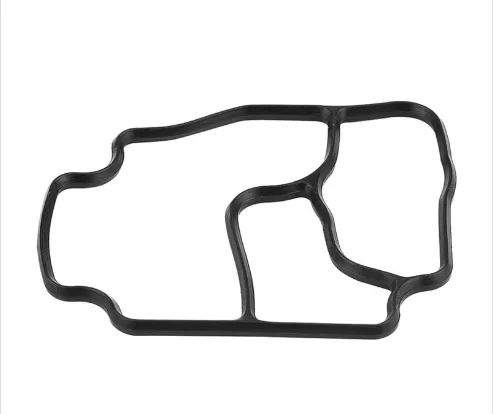

Oil seals, often referred to as rotary shaft seals or radial lip seals, are mechanical components designed to seal the spaces between stationary and moving components in machinery. Their primary function is to prevent lubricant leakage, maintain pressurization, and avoid dirt and contaminants from entering critical systems. Their applications span across numerous industries, including automotive, aerospace, manufacturing, and agriculture.

When choosing an oil seal manufacturer, several factors should guide your decision

1. Experience and Expertise Opt for manufacturers with a proven track record in producing high-quality oil seals. Experienced manufacturers typically offer a diverse range of seals made from different materials, catered to various industrial needs. This level of expertise ensures that their products can withstand demanding environments, providing reliable sealing solutions for different rotary applications.

2. Material Innovation A reputable manufacturer invests in material innovation. The choice of material, often ranging from nitrile rubber and silicone to PTFE, plays a critical role in the seal's performance. Advanced oil seals are designed to tolerate extreme temperatures and corrosive environments, tailored to meet specific industry requirements. Manufacturers that stay ahead in material technology add notable value, contributing to the extended lifespan and efficiency of the equipment.

oil seal manufacturers

3. Customized Solutions Leading manufacturers offer customized solutions, understanding that off-the-shelf products may not always meet unique application requirements. Collaborative customization leads to enhanced precision in sealing solutions, optimizing machinery performance and aligning with the specific needs of a client’s operations.

4. Quality Assurance and Standards Trustworthy oil seal manufacturers adhere to stringent quality controls and international standards, such as ISO and TS certifications. Consistent quality assurance practices ensure that each seal produced meets the necessary specifications for safety and efficiency. Quality seals are less likely to fail, reducing downtime and maintenance costs for businesses.

5. Technical Support and After-Sales Service Exceptional manufacturers provide comprehensive technical support and after-sales service. They work closely with clients to resolve any issues, offering guidance on seal installation and maintenance. This support helps maximize the lifespan of the seals, mitigating risks of equipment failure and expanding operational uptime.

6. Sustainable Practices Increasingly, the emphasis is on manufacturers who adopt sustainable practices. Eco-friendly production processes and recyclable materials are becoming significant considerations for many companies seeking to reduce their environmental footprint. Choosing manufacturers who prioritize sustainability can enhance a company’s reputation and align with broader corporate responsibility goals.

Overall, the choice of oil seal manufacturers impacts not only the efficiency of machinery but also operational continuity and cost-effectiveness. By focusing on experience, material innovation, customization, quality assurance, robust technical support, and sustainable practices, businesses can ensure they are obtaining not just a product, but a solution that aligns with their strategic and operational goals. Making informed decisions in selecting an oil seal manufacturer can substantially contribute to a company's success, reducing risks and fostering growth in an increasingly competitive marketplace.

-

High-Quality Seal 12x22x5 for Industrial & Automotive Use | YJM Seal

News Nov.25,2025

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

Products categories