oil seal for rotating shaft

Oil Seals for Rotating Shafts An Essential Component for Sealing and Protection

In the realm of mechanical engineering and machinery maintenance, oil seals play a critical role in ensuring the longevity and efficiency of rotating shafts. These components, often overlooked, are essential for preventing the leakage of lubricants and contaminants, thus safeguarding the operational integrity of machinery in diverse industries, from automotive to industrial manufacturing.

Understanding Oil Seals

Oil seals, sometimes referred to as shaft seals or lip seals, are devices designed to retain lubricants within a mechanical system while simultaneously preventing the ingress of dirt, dust, and moisture. They are typically made from elastomers, such as nitrile rubber, silicone, or fluorocarbon, which provide excellent sealing properties and resistance to various temperatures and chemical exposures.

The design of an oil seal usually consists of a circular body with an outer diameter that fits snugly in the housing and an inner diameter that encircles the rotating shaft. The sealing surface features a lip that exerts pressure against the shaft, creating a tight seal. The quality of materials and precision in manufacturing play significant roles in the effectiveness and durability of these seals.

Application in Rotating Shafts

Rotating shafts are found in numerous applications, from electric motors and gearboxes to pumps and industrial machinery. Each of these applications demands precise sealing to ensure proper lubrication and to minimize wear and tear. Oil seals are specifically engineered to address the dynamic conditions present in these scenarios.

For instance, in an automotive engine, oil seals are essential to keep engine oil from leaking out while preventing contaminants from entering the engine. The failure of an oil seal can lead to serious consequences, including reduced lubrication, increased friction, overheating, and ultimately, engine failure. Similarly, in industrial applications, oil seals not only protect against leaks but also enhance the efficiency of rotating equipment by maintaining optimal lubrication conditions.

Choosing the Right Oil Seal

oil seal for rotating shaft

Selecting the appropriate oil seal for a specific application requires careful consideration of several factors. Key aspects include

1. Material Compatibility Different materials are suited for different types of oils and operating conditions. For example, silicone seals may be ideal for high-temperature applications, while nitrile seals excel in environments involving petroleum oils.

2. Operating Conditions The operating temperature, pressure, and speed of the rotating shaft must be evaluated. High-speed applications may require seals designed to withstand increased centrifugal forces, while extreme temperature ranges necessitate materials with appropriate thermal stability.

3. Shaft Finish and Tolerance The surface finish and tolerances of the shaft play a pivotal role in sealing effectiveness. A smooth, properly machined surface on the shaft contributes to a better seal and extends the lifespan of the oil seal.

4. Seal Design Various designs exist for oil seals, including single-lip, double-lip, and S-type seals. Each configuration offers different sealing capabilities and is suited to specific applications.

Maintenance and Replacement

Regular inspection and maintenance of oil seals are crucial for preventing equipment failures. Signs of wear, such as visible leaks, dirt accumulation, or unusual noises from rotating machinery, can indicate that an oil seal needs replacement. Prompt action can avert costly downtime and extensive damage to machinery.

Conclusion

Oil seals for rotating shafts may seem like small components in a vast array of mechanical systems, but their importance cannot be overstated. By effectively sealing lubricants while keeping contaminants at bay, these seals help maintain operational efficiency and prolong the lifespan of machinery. When selecting, installing, and maintaining oil seals, a meticulous approach can lead to significant benefits in performance and reliability. In an industry where downtime and repairs can incur high costs, investing in quality oil seals is a smart choice that plays a vital role in safeguarding the integrity of rotating shafts and the systems they operate within.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

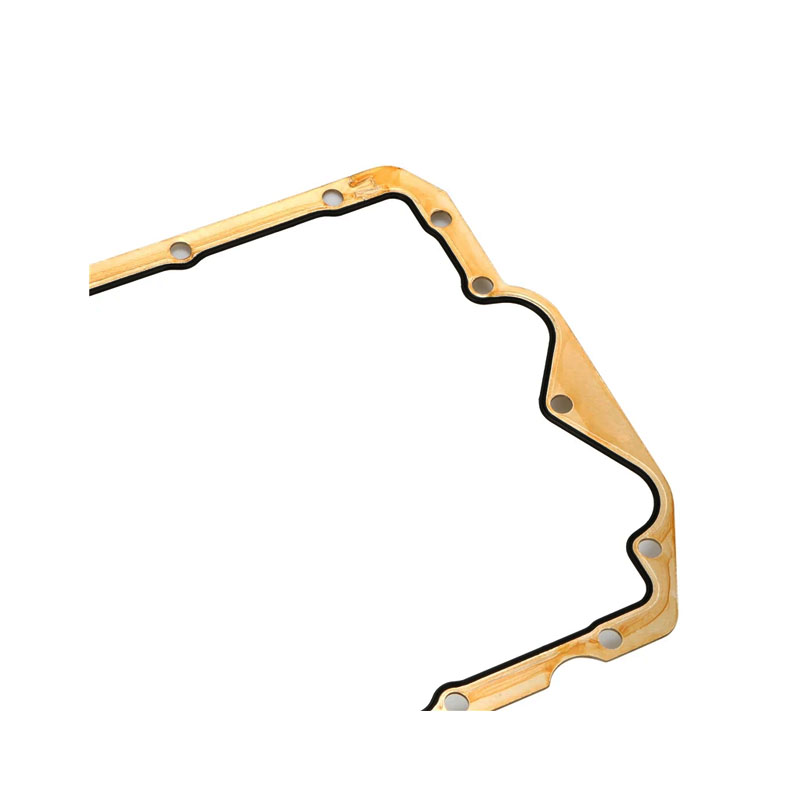

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories