oil seal for rotating shaft

Understanding Oil Seals for Rotating Shafts

Oil seals, also known as shaft seals or oil rings, play a crucial role in various mechanical systems by preventing the leakage of fluids and contaminants. These seals are specifically designed for rotating shafts, making them indispensable in many industries, from automotive to manufacturing. This article aims to provide an overview of oil seals for rotating shafts, including their types, functions, applications, and maintenance considerations.

What Are Oil Seals?

Oil seals are circular sealing devices that fit around rotating shafts. Their primary function is to block the escape of lubricating oils and to prevent dirt, dust, and other contaminants from entering the machinery. They are typically made from elastomers, such as nitrile rubber, silicone, or fluorocarbon, depending on the application requirements. The choice of material affects the seal's durability, resistance to temperature fluctuations, and compatibility with various fluids.

Types of Oil Seals

There are several types of oil seals designed for different applications

1. Single Lip Oil Seals These seals have a flexible lip that contacts the shaft, creating a barrier against the fluid. They are commonly used in non-pressurized systems.

2. Double Lip Oil Seals With two flexible lips, these seals provide an extra layer of protection, making them ideal for preventing contamination while still allowing the internal lubrication of the shaft.

3. Spring-Loaded Oil Seals Incorporating a spring mechanism, these seals exert constant pressure against the shaft, ensuring a tighter seal and helping to compensate for wear over time.

4. Metal-Cased Oil Seals These seals offer added stability and resistance to the environmental elements. They are often used in heavy machinery where extra durability is needed.

Functions and Importance

The primary function of oil seals is to ensure the operational efficiency of rotating machinery

. They serve several critical purposesoil seal for rotating shaft

- Leak Prevention Oil seals prevent lubricants from leaking out of the equipment, which maintains the efficiency of lubrication and reduces wear on moving parts. - Contaminant Exclusion By preventing dirt and other contaminants from entering, oil seals help maintain the integrity of the lubrication system, thereby increasing the lifespan of the machinery.

- Pressure Maintenance In pressurized systems, oil seals help maintain the necessary pressure for optimal operation.

Failing to incorporate quality oil seals can lead to significant issues, such as increased maintenance costs, reduced equipment lifespan, and potential system failures due to overheating or contamination.

Applications of Oil Seals

Oil seals are used in various applications across multiple industries

- Automotive In vehicles, oil seals are used in engines, transmission systems, and differentials to keep the fluids contained and ensure smooth operation.

- Aerospace High-performance aircraft engines rely on oil seals for efficient functioning, especially under extreme conditions.

- Industrial Equipment Machinery in manufacturing plants often requires oil seals to prevent oil leaks and protect against contaminants.

- Home Appliances Many household appliances, such as washing machines and refrigerators, utilize oil seals to enhance their performance and durability.

Maintenance and Replacement

Regular inspection of oil seals is essential for maintaining equipment performance. Signs of wear, such as leaks or abnormal noises, indicate that the seals may need replacement. Proper installation is crucial; an incorrectly fitted seal can lead to premature failure.

In conclusion, oil seals are vital components for rotating shafts, ensuring efficient operation and longevity of machinery. Their significance spans various industries, highlighting the need for proper selection, installation, and maintenance. By understanding the types and functions of oil seals, operators can better manage their equipment and avoid costly downtimes due to seal failures.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

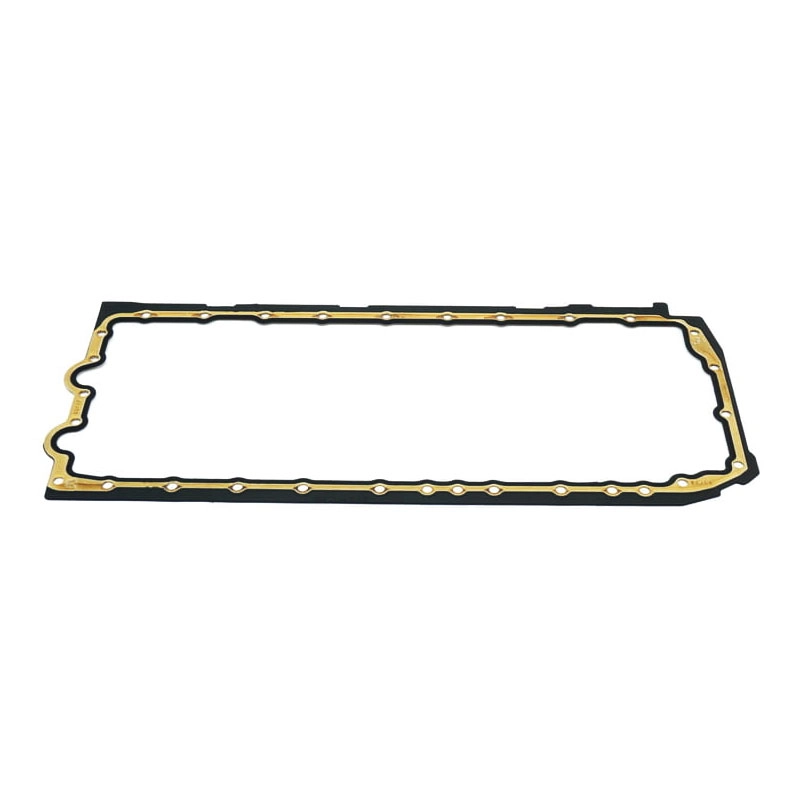

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories