Top Manufacturers of Oil Seals for Your Industrial Needs

Exploring the World of Oil Seal Companies

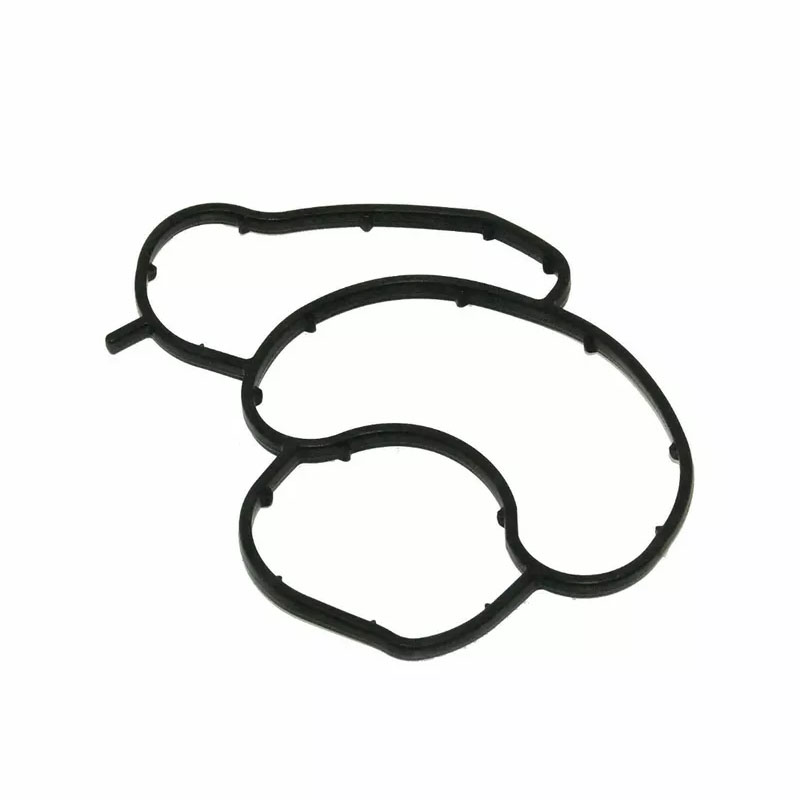

Oil seals, also known as grease seals or rotary seals, are vital components in various machinery and equipment. They play a crucial role in preventing the leakage of lubricants and fluids, which is essential for the smooth operation and longevity of mechanical systems. As industries evolve, the demand for high-quality oil seals has led to the emergence and growth of numerous oil seal companies worldwide. This article will delve into the significance of oil seal manufacturers, their products, and the factors that contribute to their success in this competitive market.

Understanding Oil Seals

Oil seals are designed to retain lubricants and prevent contaminants from entering machinery. They are commonly used in various applications, including automotive, aerospace, industrial machines, and household appliances. The effectiveness of these seals is critical, as failures can result in increased wear and tear, leading to costly repairs and downtime.

Manufacturers produce oil seals from various materials, including rubber, polyurethane, and silicone, among others. Each material type has its unique properties, making it suitable for specific applications. For instance, nitrile rubber is often used for its excellent resistance to petroleum-based fluids, while fluorocarbon rubber is preferred in high-temperature environments.

The Role of Oil Seal Companies

Oil seal companies specialize in the design, manufacture, and distribution of oil seals. They typically offer a wide range of products tailored to meet the diverse needs of their customers. These companies are crucial in ensuring that machinery operates efficiently and reliably through their innovative products.

1. Design and Engineering Expertise Leading oil seal companies invest in cutting-edge technology and skilled engineers to develop seals that can withstand extreme conditions. This includes high pressure, temperature variations, and exposure to corrosive substances. Custom design services are often available, allowing clients to specify their unique requirements.

oil seal companies

2. Quality Assurance To maintain competitiveness, oil seal companies emphasize quality control throughout the manufacturing process. This includes sourcing high-quality raw materials, conducting thorough testing, and adhering to international standards. Certifications such as ISO 9001 are often sought to demonstrate commitment to quality.

3. Research and Development Innovation is key in the oil seal industry. Companies that prioritize research and development can create new materials and designs that enhance seal performance. This not only improves the longevity of the seals but also helps reduce maintenance costs for end-users.

4. Customer Support Oil seal companies understand the importance of customer service. Providing technical support, timely delivery, and responsive communication are essential for building long-term relationships. Many companies also offer training and resources to help customers select the appropriate seals for their specific applications.

Market Trends and Challenges

The oil seal market is influenced by several trends, including the growing emphasis on sustainability, advancements in material technology, and the increasing demand for high-performance seals in emerging industries such as electric vehicles and renewable energy. Companies are exploring eco-friendly materials and production methods to meet the evolving expectations of consumers and regulatory standards.

However, challenges such as fluctuating raw material prices and intense competition necessitate that companies remain agile and responsive to market changes. Establishing a strong brand reputation and staying ahead of industry trends can set successful companies apart from their competitors.

Conclusion

Oil seal companies are integral to various industries' operational efficiency and reliability. Their commitment to quality, innovation, and customer satisfaction has positioned them as essential partners in machinery maintenance and performance. As technology continues to advances and industries evolve, these companies will play a pivotal role in providing the solutions needed to meet the demands of the modern world. With ongoing research and development, the future of oil seal manufacturing looks promising, paving the way for enhanced performance and sustainability in machinery applications.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories