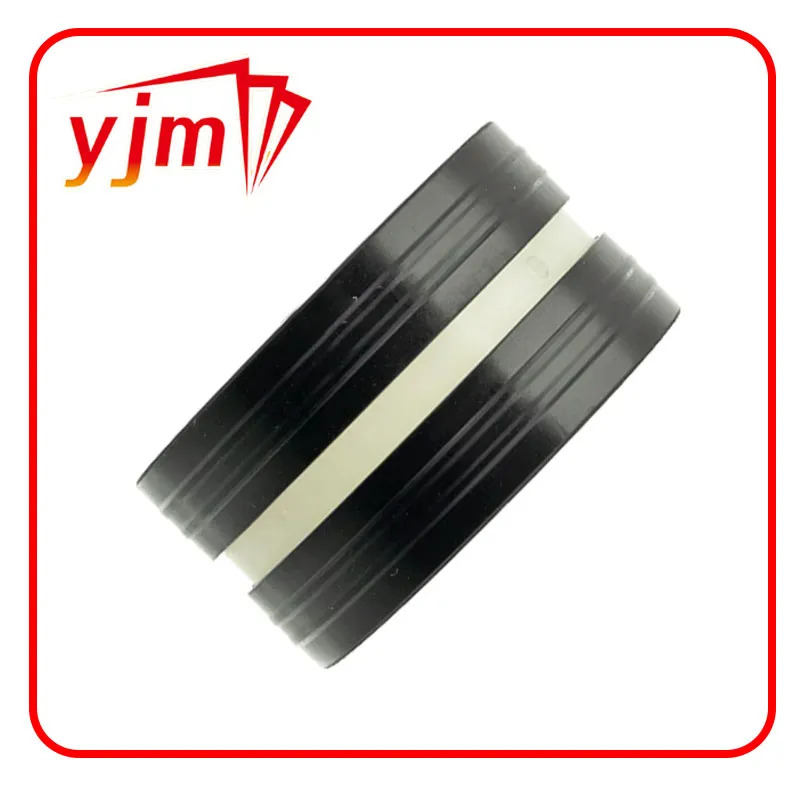

oil seal china

Understanding Oil Seals in China A Comprehensive Overview

Oil seals, also known as grease seals or shaft seals, play a crucial role in various mechanical systems, ensuring the optimal performance and longevity of machinery. In China, the production and supply of oil seals are significant due to the country's extensive manufacturing industry that spans automotive, aerospace, and consumer goods, among others. This article explores the importance of oil seals, factors driving their manufacturing in China, and the current market trends.

What Are Oil Seals?

Oil seals are mechanical components designed to seal in lubricants and keep out dirt, debris, and moisture from entering machinery. They are critical in reducing friction between moving parts, which, in turn, enhances the efficiency of engines and other mechanical systems. Typically made from materials like rubber or thermoplastics, oil seals come in various shapes and sizes to fit different applications.

The Importance of Oil Seals

1. Performance Enhancement Proper sealing minimizes the risk of lubricant leakage, which is vital for the correct functioning of machinery. This performance enhancement translates to better fuel efficiency and reduced operational costs.

2. Longevity By preventing contaminants from entering the system, oil seals significantly extend the lifespan of equipment. This durability is particularly important in sectors like automotive manufacturing, where the quality and reliability of components are paramount.

3. Safety In certain applications, such as aviation or high-speed machinery, the failure of an oil seal can lead to catastrophic results. Proper sealing protects not only the machine but also human safety.

Manufacturing Landscape in China

China is considered one of the world's largest manufacturers of oil seals. The country boasts a substantial number of factories specializing in the production of various seals, catering to both domestic and international markets.

oil seal china

1. Economies of Scale Chinese manufacturers benefit from economies of scale, enabling them to produce high volumes of oil seals at competitive prices. This translates into lower costs for consumers and businesses looking to procure these essential components.

2. Innovation and Technology With advancements in materials science and engineering, many Chinese companies have invested in modern manufacturing technologies. This focus on R&D has led to the production of high-performance oil seals that meet international standards.

3. Export Potential China has positioned itself as a global supplier of oil seals, exporting to markets in North America, Europe, and beyond. The robust supply chain and logistics capabilities make it easier for manufacturers to reach international customers quickly.

Market Trends

The oil seal market in China has experienced significant growth in recent years, driven by several factors

1. Increasing Demand from the Automotive Industry With the burgeoning automotive sector in China, the demand for oil seals has surged. Electric vehicles (EVs) also present new opportunities, requiring specialized sealing solutions.

2. Emphasis on Quality Standards As international standards become more stringent, Chinese manufacturers are adapting to regulations related to material safety and environmental impact. This commitment to quality is essential for maintaining competitiveness in global markets.

3. Sustainability Initiatives Many companies are now adopting sustainable practices in their manufacturing processes. This shift not only enhances corporate responsibility but also appeals to environmentally conscious consumers and businesses.

Conclusion

In summary, oil seals are vital components in various mechanical applications, and their production in China represents a crucial element of the country’s manufacturing landscape. With solid demand driven by industries like automotive and aerospace, coupled with advancements in technology and manufacturing processes, the oil seal market in China is set for continued growth. As quality standards evolve and sustainability becomes increasingly important, manufacturers must stay agile to meet these new challenges while ensuring that their products perform reliably in a wide range of applications. This ongoing development highlights China's significant role in the global oil seal industry and its commitment to maintaining high standards in both production and product efficacy.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories