High-Quality 65 85 10 Oil Seal for Enhanced Performance and Durability

Understanding Oil Seals The 65x85x10 Specification

Oil seals play a crucial role in various mechanical systems by preventing lubricants from leaking out and contaminants from entering machinery. One specific type of oil seal that is widely used across different industries is the 65x85x10 oil seal. This designation refers to the dimensions of the seal 65 mm in inner diameter, 85 mm in outer diameter, and a 10 mm thickness. Understanding the features and applications of this oil seal can help in making informed decisions regarding maintenance and equipment longevity.

Design and Construction

The 65x85x10 oil seal typically consists of a rubber or elastomeric material, which provides elasticity and strength. The inner diameter slides over a shaft, while the outer diameter is fixed into a housing. The thickness of 10 mm ensures that the seal can accommodate slight variations in shaft dimensions and housing tolerances, making it versatile for different applications. Additionally, many oil seals are reinforced with a metal casing, improving resistance against wear and enhancing sealing performance.

Functionality

Understanding Oil Seals The 65x85x10 Specification

Applications

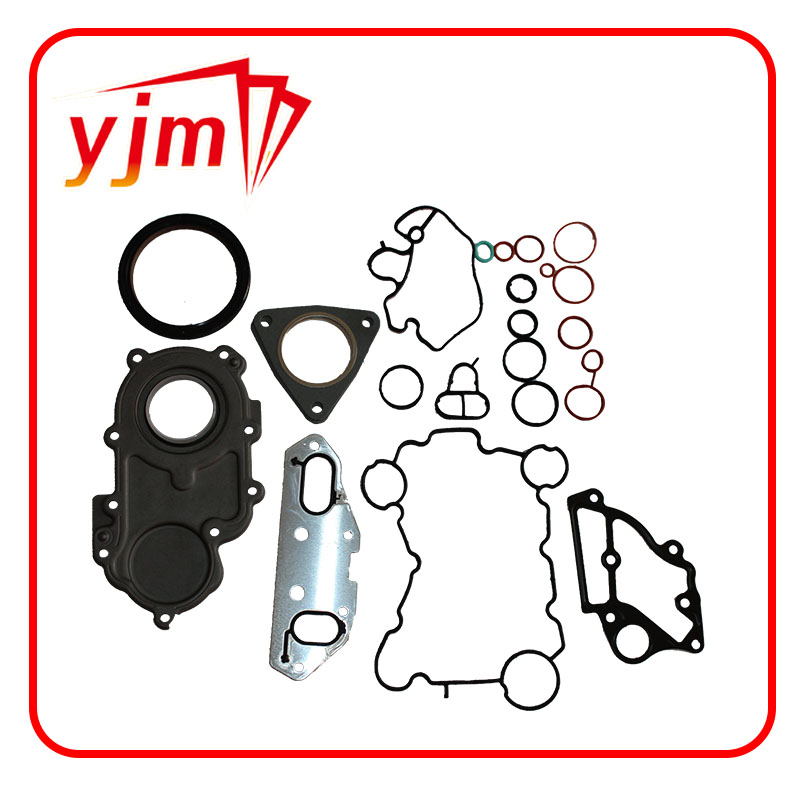

oil seal 65 85 10

The 65x85x10 oil seal is commonly found in a variety of applications. In automotive contexts, it is used in engines, transmissions, and differentials to keep oil contained and ensure optimal performance. In industrial machinery, these seals often find their place in pumps, compressors, and gear systems. Additionally, they are critical in agricultural machinery, construction equipment, and even in the manufacturing of consumer products. The versatility of this oil seal makes it a go-to choice for engineers and maintenance professionals across various sectors.

Benefits of Quality Oil Seals

Investing in high-quality oil seals, such as the 65x85x10 variant, offers several benefits. First and foremost, quality seals reduce the risk of leaks, which can lead to costly downtime and repairs. By effectively sealing crucial components, they help to extend the lifespan of the equipment and improve overall operational efficiency. Furthermore, reliable oil seals minimize the entry of contaminants, which can cause wear and tear on critical moving parts, further enhancing the longevity of the machinery.

Maintenance and Replacement

Regular maintenance checks play a pivotal role in ensuring the integrity of oil seals. Signs of wear, such as stains from leaking oil, excessive noise, or decreased performance, indicate that it may be time for a replacement. The process of replacing a 65x85x10 oil seal generally involves removing the old seal, cleaning the shaft and housing, and installing the new seal carefully to prevent damage.

In conclusion, the 65x85x10 oil seal is a small yet vital component in a wide array of machinery. Understanding its importance and ensuring its proper maintenance can lead to improved operational reliability and efficiency. Properly functioning oil seals not only help protect the machinery but also contribute significantly to overall productivity. By choosing the right oil seal, businesses can safeguard their investments and ensure their equipment operates smoothly for years to come.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories