oil seal 50 * 72 * 10

Understanding Oil Seals The 50 * 72 * 10 Standard

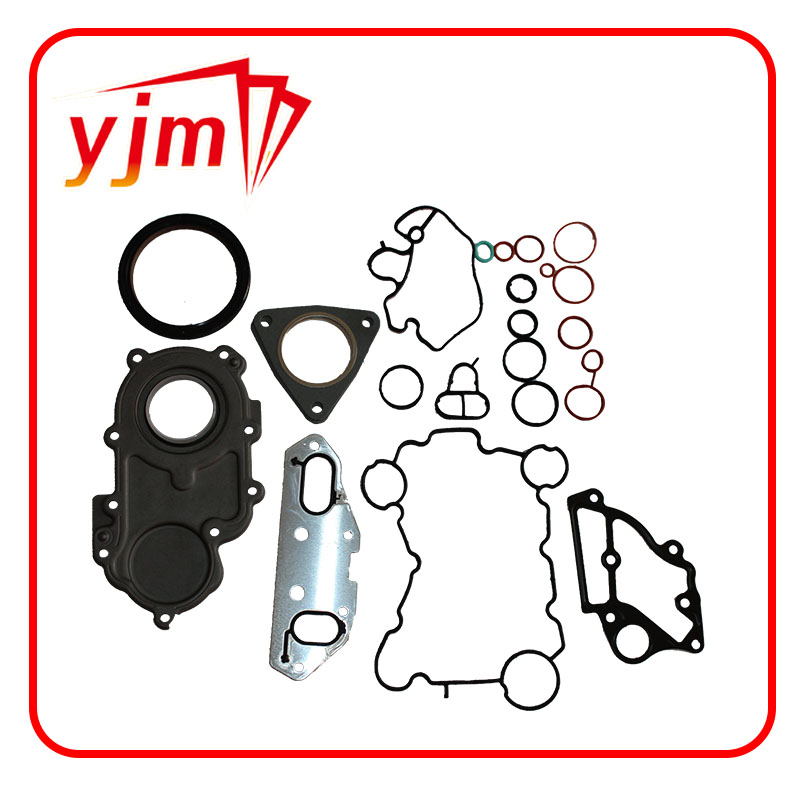

Oil seals are critical components in numerous mechanical systems, providing essential sealing functions that help prevent leaks and maintain the efficiency of machinery. One common type of oil seal is specified as 50 * 72 * 10, which refers to its dimensions a 50 mm inner diameter, a 72 mm outer diameter, and a 10 mm thickness. These seals are widely used in various applications, including automotive engines, industrial machinery, and hydraulic systems.

The Function of Oil Seals

At its core, an oil seal serves to isolate components within a machine, preventing the escape of lubricants and the ingress of contaminants. This sealing action is vital for ensuring that the machinery operates smoothly and efficiently. Without effective seals, oil can leak from the system, leading to lubrication failure, increased wear on moving parts, and, ultimately, failure of the machinery. Moreover, external contaminants such as dust, dirt, and moisture can infiltrate the system, causing further damage and reducing efficiency.

Design and Materials

The design of an oil seal must account for the specific operating conditions of the machinery in which it is used. Factors such as temperature, pressure, and the type of fluid being sealed all influence the selection of materials and design features of the seal. For the 50 * 72 * 10 oil seal, manufacturers typically utilize synthetic rubber compounds known for their durability and resistance to wear. Additionally, many oil seals are designed with a spring-loaded lip that helps maintain contact with the shaft and enhances sealing performance under varying operational conditions.

Applications of 50 * 72 * 10 Oil Seals

oil seal 50 * 72 * 10

Several industries rely on the standard 50 * 72 * 10 oil seal due to its versatile dimensions and robust performance. In the automotive sector, these seals are commonly found in engine assemblies, transmission systems, and differential housings. They play a crucial role in preventing engine oil leaks and ensuring that the transmission fluid remains contained, thereby protecting the critical internal components.

In industrial settings, the 50 * 72 * 10 oil seal is often employed in pumps, gearboxes, and hydraulic systems. In hydraulic applications, the sealing capability is essential for maintaining pressure and ensuring that hydraulic fluid does not escape, which could lead to system malfunction or safety hazards.

Installation and Maintenance

Proper installation of oil seals is crucial for their effective operation. Before installation, it is important to inspect the sealing surface for any scratches or damage that could compromise the seal’s integrity. During installation, care must be taken to avoid applying excessive force that could distort the seal or damage its surface.

Routine maintenance and inspection of oil seals can significantly extend their lifespan. Checking for signs of leakage, wear, or damage can help identify issues before they result in catastrophic failures. Replacing oil seals at the first sign of wear can prevent more extensive damage to surrounding components and ensure the continued operation of the machinery.

Conclusion

In conclusion, the oil seal, specifically the 50 * 72 * 10 model, plays a pivotal role in the reliability and efficiency of various mechanical systems. By preventing leaks and excluding contaminants, these seals protect vital machinery components and contribute to overall operational success. Understanding the importance of oil seals and their correct application can lead to enhanced performance and reduced downtime in both automotive and industrial contexts. As technology continues to advance, further developments in seal materials and designs will undoubtedly improve the functionality and longevity of these indispensable components.

-

High-Quality Seal 12x22x5 for Industrial & Automotive Use | YJM Seal

News Nov.25,2025

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

Products categories