oil seal 50 70 10

Understanding Oil Seals The Importance of the 50-70-10 Variant

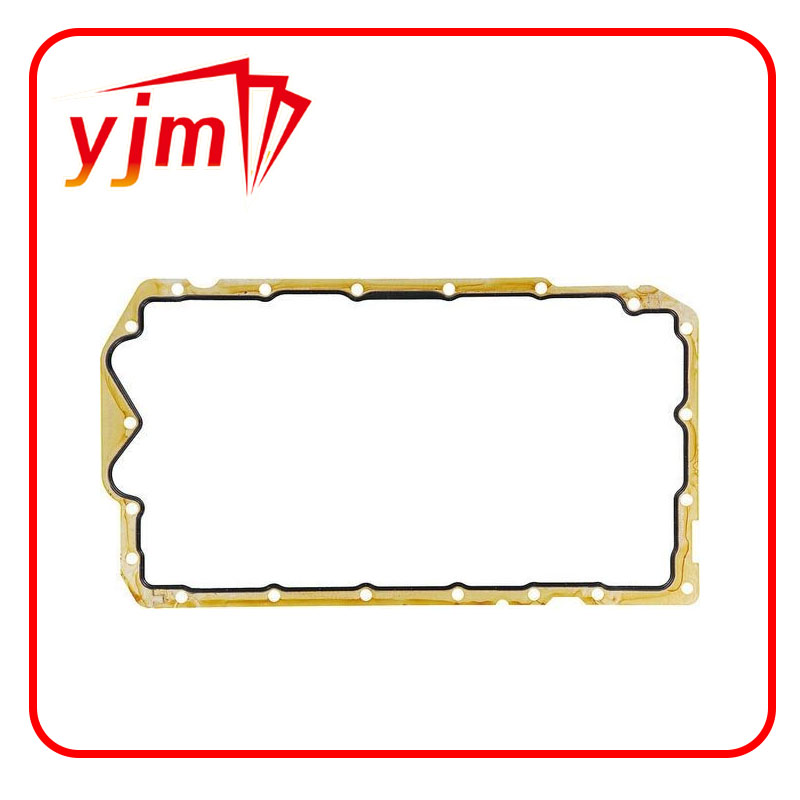

Oil seals, commonly referred to as lip seals or rotary shaft seals, are essential components in machinery and automotive applications. Designed to prevent the leakage of fluids, they play a critical role in maintaining the efficiency and longevity of mechanical systems. One notable variant worth discussing is the 50-70-10 oil seal, which is defined by its dimensions a 50 mm outer diameter, a 70 mm inner diameter, and a 10 mm cross-section.

Design and Materials

The 50-70-10 oil seal typically features a rubber or elastomeric material that provides the necessary flexibility and cushioning to create a tight seal around moving components. The design includes a lip that conforms to the shaft's surface, effectively blocking the escape of lubricants and the entrance of contaminants. The choice of material is crucial; it must withstand various conditions such as temperature fluctuations, chemical exposure, and wear from friction. Common materials include Nitrile (Buna-N), Viton, and silicone, each selected based on the specific application and environmental factors.

Applications

Oil seals like the 50-70-10 are widely used in various industries, including automotive, aerospace, manufacturing, and consumer appliances. In vehicles, they are often found in the engine, transmission, and differential. Their ability to keep oil contained prevents leaks that could lead to severe mechanical failures and costly repairs. In industrial machinery, oil seals protect gearboxes and hydraulic systems, ensuring they operate seamlessly and efficiently.

oil seal 50 70 10

Functionality and Importance

The primary function of the 50-70-10 oil seal is to retain lubricants and protect the internal components of machinery from dirt, dust, and moisture. This function is critical because the presence of foreign particles can lead to increased wear, overheating, and ultimately, mechanical failure. By ensuring a tight seal, these oil seals contribute significantly to reducing maintenance needs and extending the service life of equipment.

Installation and Maintenance

Proper installation of the 50-70-10 oil seal is vital for its performance. It should be correctly aligned and seated without damage to the sealing lip. Regular inspections can also help in identifying any wear or degradation in the seal, allowing for timely replacements before a leak occurs. Understanding the signs of a failing oil seal, such as oil spots under machinery or lower-than-normal lubricants, can save substantial repair costs and downtime.

Conclusion

In conclusion, the 50-70-10 oil seal is a pivotal component in numerous applications, ensuring operational efficiency and protecting intricate machinery from potential damage. By understanding its design, applications, and importance, users can appreciate the role these seals play in both everyday devices and heavy industrial equipment. Investing in quality oil seals and ensuring they are correctly installed and maintained can greatly enhance machinery performance and reliability.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories