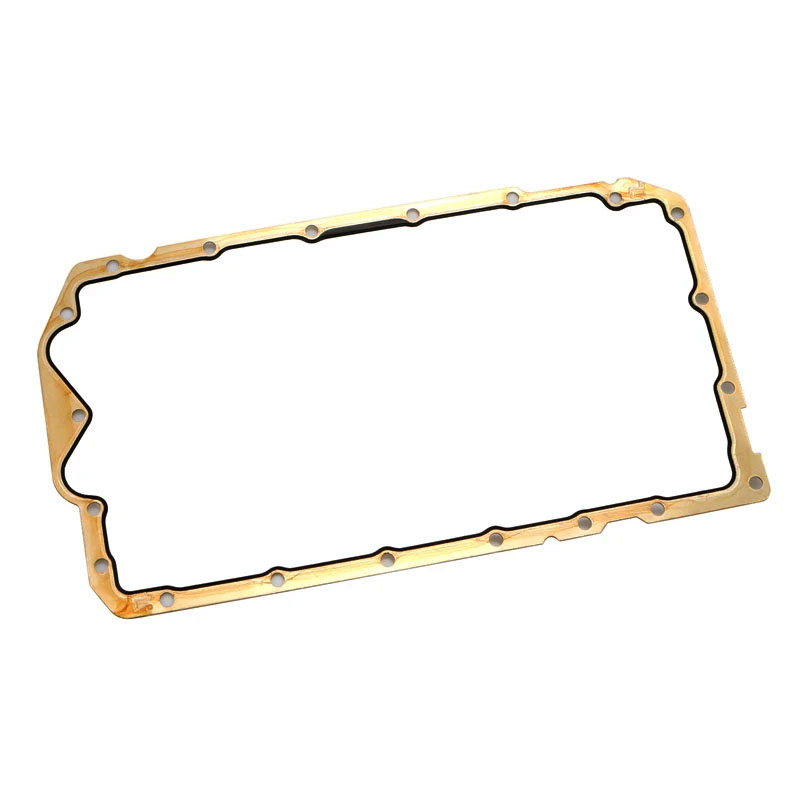

oil seal 45 62 8

Understanding the Importance and Applications of Oil Seals The 45x62x8 Specification

Oil seals are crucial components in various mechanical systems, as they play a vital role in preventing leakage of fluids and contaminants while maintaining the necessary lubrication within machinery. Among the various types and sizes available, the oil seal specified as 45x62x8 has gained popularity for its versatile applications in automotive and industrial settings. In this article, we will explore the definition, components, applications, and maintenance of the 45x62x8 oil seal.

What is an Oil Seal?

An oil seal, also known as a radial shaft seal, is a mechanical device that fills the gap between a rotating shaft and its housing or casing. Its primary function is to retain lubricating oil while preventing the ingress of dirt, dust, and other contaminants that can cause wear and tear on the moving parts of a machine. Oil seals are generally made from elastomers and can be designed to withstand various operating conditions, including temperature fluctuations, chemical exposure, and pressure variations.

Specifications of the 45x62x8 Oil Seal

The numbers in the designation 45x62x8 refer to the dimensions of the oil seal - 45 mm Inner diameter (the size that fits onto the shaft) - 62 mm Outer diameter (the size that fits into the housing) - 8 mm Width (the thickness of the seal)

These dimensions indicate that the oil seal is ideally suited for applications that require a robust sealing solution in compact spaces.

Material Composition

Oil seals can be made from various materials, including nitrile rubber (NBR), fluorocarbon rubber (FKM), and silicone rubber, among others. The choice of material typically depends on the operating environment. For example, NBR is commonly used for standard oil sealing applications due to its excellent resistance to petroleum-based oils and a wide range of temperatures. In contrast, FKM seals are used in more demanding conditions, where high temperatures and aggressive chemicals are present.

Applications of the 45x62x8 Oil Seal

oil seal 45 62 8

The 45x62x8 oil seal finds applications in various industries, including automotive, manufacturing, and oil and gas. Some common uses include

1. Automotive Engines Used in crankshafts, camshafts, and gearboxes, the oil seal helps maintain lubrication while preventing oil leaks that can lead to engine failure.

2. Pumps and Compressors Oil seals are integral to pumps and compressors, ensuring that lubricants remain contained and efficiently circulate without contamination.

3. Industrial Machinery Equipment such as hydraulic cylinders, conveyors, and gearboxes often utilize oil seals like the 45x62x8 to maintain operational efficiency by preventing contaminant ingress.

4. Marine Applications In the marine industry, oil seals are used in applications such as propeller shafts and gearboxes, where moisture resistance is crucial.

Maintenance and Replacement

Regular maintenance of oil seals can help prolong their life and ensure optimal performance. Signs that an oil seal may need replacement include visible leaks, increased noise from the machinery, or reduced lubrication effectiveness. During replacement, it is essential to clean the sealing surfaces properly, use the correct installation technique, and ensure that the new oil seal matches the specified dimensions (45x62x8) and material requirements for the specific application.

Conclusion

The 45x62x8 oil seal is an essential component in various mechanical systems that require reliable sealing solutions. By understanding its specifications, applications, and maintenance practices, engineers and technicians can ensure that machinery operates smoothly and effectively, reducing downtime and extending the life of mechanical components. In a world where efficiency and reliability are paramount, investing in quality oil seals is undoubtedly a wise choice.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories