Oil Seal Dimensions 40x52x7 for Optimal Performance and Durability Use

Understanding Oil Seals Focus on the 40 52 7 Specifications

Oil seals, also known as lip seals or rotary shaft seals, are essential components in various mechanical systems, ensuring the efficient operation and longevity of machinery. Among the myriad specifications, one that stands out in specific applications is the oil seal designated as 40 52 7. This article explores the importance, functionality, and applications of oil seals, with a particular focus on the 40 52 7 specification.

What is an Oil Seal?

An oil seal is a device that prevents the leakage of lubricants while protecting bearings and other vital components from contaminants such as dust and dirt. Typically made from materials like rubber, silicone, or metal, oil seals are designed to accommodate the rotational movement of shafts, providing a reliable barrier against external elements and maintaining the internal lubrication system of machinery.

The primary functions of oil seals include

1. Preventing Leakage They serve as a barrier that prevents lubricants from leaking out of the system, thereby ensuring that the machinery operates smoothly without compromising its lubrication. 2. Keeping Contaminants Out Oil seals prevent dust, dirt, and water from entering the lubrication system, which can cause wear and premature failure of components.

3. Maintaining Pressure They help maintain the pressure within a system, which is crucial for the optimal performance of hydraulic systems and certain mechanical assemblies.

Understanding the 40 52 7 Specification

The specification 40 52 7 refers to the dimensions and features of a specific oil seal. In this case, the numbers can be broken down as follows

- 40 mm This is the inner diameter of the oil seal. It indicates the size of the shaft that the seal is designed to fit onto. - 52 mm This is the outer diameter of the seal, which specifies the outer size that will fit into the housing or bore of the machinery. - 7 mm This number denotes the thickness of the seal. It is crucial for determining the seal's compatibility with various mechanical assemblies.

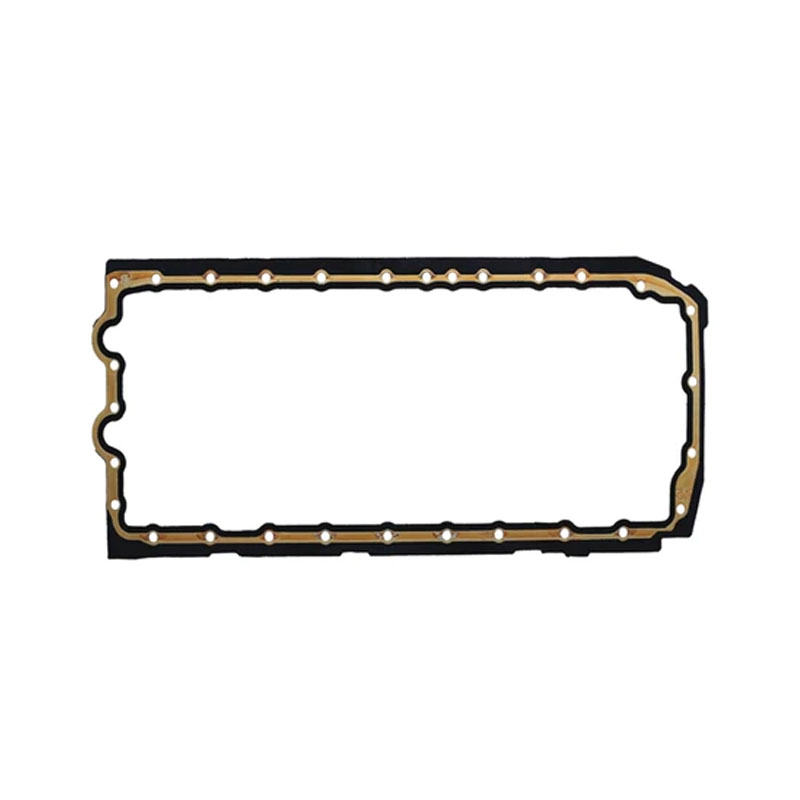

oil seal 40 52 7

These dimensions are critical for ensuring that the oil seal fits properly within the designated components, thereby maximizing effectiveness. An incorrectly sized seal can lead to leakage, contamination, and ultimately failure of the component it is designed to protect.

Applications of the 40 52 7 Oil Seal

The 40 52 7 oil seal is utilized in a variety of applications across different industries. Some common applications include

1. Automotive In vehicles, oil seals are used in engines, transmissions, and differentials to keep oil contained and prevent contamination from dirt and water. The 40 52 7 oil seal is particularly suitable for certain models and types of machinery, ensuring that vital lubricants remain intact.

2. Industrial Machinery Various types of industrial equipment, such as pumps and motors, utilize oil seals to prevent leaks and protect bearings. The 40 52 7 seal can be found in hydraulic systems and gearboxes, where pressure and cleanliness are crucial for operational efficiency.

3. Agricultural Equipment Tractors and other farm machinery often rely on these seals to prevent the loss of hydraulic fluids and maintain the integrity of the engine compartments.

4. Home Appliances Some household appliances, like washing machines and dishwashers, also employ oil seals in motors and pumps, where water and lubrication are interdependent.

Conclusion

The 40 52 7 oil seal is a prime example of how specific designations can play a critical role in machinery performance. Its ability to prevent leakage and contamination makes it an indispensable component in various applications, from automotive sectors to industrial machinery. Understanding the importance and functionality of oil seals is vital for anyone involved in mechanical design, maintenance, or operation, ensuring that machinery runs smoothly and efficiently over its lifespan.

As technology advances and machinery becomes more complex, the need for high-quality oil seals will only continue to grow, making models like the 40 52 7 essential for modern engineering. Investing in reliable oil seals is not merely a matter of performance; it is a commitment to ensuring the longevity and efficiency of machines across all industries.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories