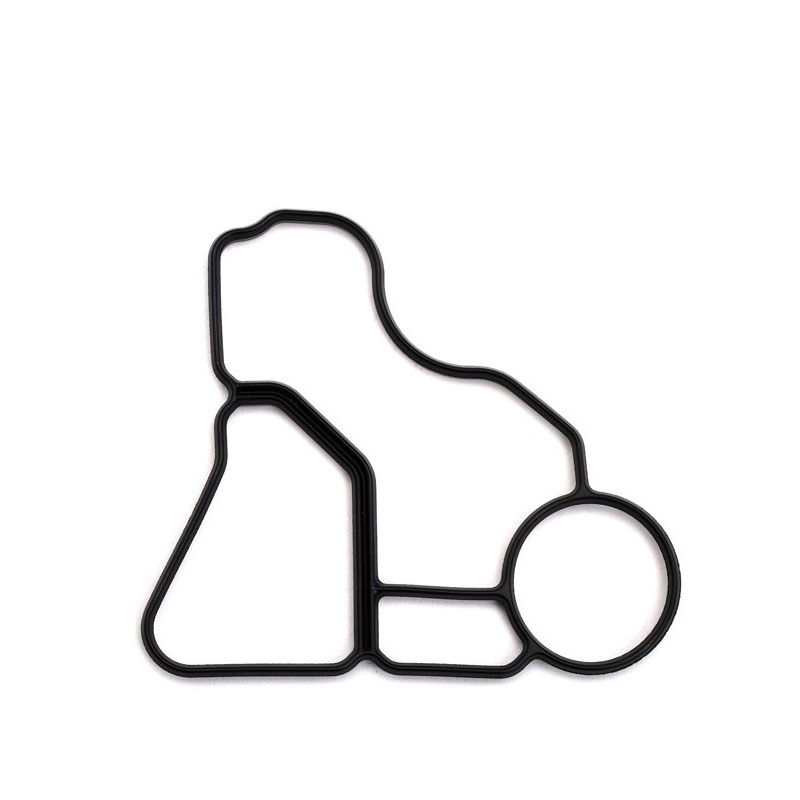

oil seal 30 52 10

Understanding Oil Seals The Case of the 30 52 10 Model

Oil seals are critical components in many mechanical systems, playing an essential role in preventing the leakage of fluids and the ingress of contaminants. Among various types of oil seals, the 30 52 10 specification has gained attention in both industrial and automotive applications. Understanding the features, applications, and benefits of oil seals like the 30 52 10 can help manufacturers and engineers make informed decisions for their projects.

What is an Oil Seal?

An oil seal, also known as a lip seal or fluid seal, is designed to retain lubricants such as oils and greases while excluding dirt, dust, and other contaminants from entering a mechanism. These seals usually consist of an elastomeric material and may include a metal casing to enhance structural integrity. The sealing function is typically provided by one or more flexible lips that create a tight fit against a rotating shaft or static surface.

The Specifications 30 52 10

The designation 30 52 10 refers to the dimensions of a specific type of oil seal. In this case, the numbers represent the seal's inner diameter (30 mm), outer diameter (52 mm), and height or thickness (10 mm). These dimensions are crucial for ensuring a proper fit within the equipment it is intended for. An accurately sized oil seal ensures optimal performance and minimizes the risk of leaks.

Material Composition

Oil seals are available in various materials, each suited for different applications based on temperature, pressure, and the type of fluid being contained. Common materials include nitrile rubber (NBR), fluorocarbon rubber (FKM), and polyacrylate. The 30 52 10 model can be made from one of these materials to match the specific requirements of the application. For example, NBR is resilient to petroleum-based oils and suitable for moderate temperatures, whereas FKM offers better resistance to high temperatures and aggressive chemicals.

Applications of the 30 52 10 Oil Seal

oil seal 30 52 10

The versatility of the 30 52 10 oil seal makes it suitable for a wide range of applications. This specific model is often used in automotive engines, hydraulic systems, pumps, and gearboxes. In automotive contexts, it can be found in crankshaft and camshaft applications, where effective sealing is vital for maintaining oil pressure and preventing leaks. In industrial machinery, these seals help maintain lubrication within rotating shafts, ensuring smooth operation and extending the life of the equipment.

Benefits of Using Oil Seals

Utilizing oil seals like the 30 52 10 brings several advantages

1. Leak Prevention One of the primary functions of an oil seal is to prevent the escape of lubricants. This not only helps in conserving resources but also ensures that machinery operates efficiently.

2. Contaminant Exclusion Oil seals effectively block dirt, dust, and debris from entering critical components, reducing wear and tear and enhancing the reliability of machinery.

3. Extended Equipment Life By maintaining proper lubrication and preventing contamination, oil seals contribute significantly to the longevity of mechanical systems.

4. Ease of Replacement Oil seals are generally easy to replace, minimizing downtime in industrial applications and reducing maintenance costs.

Conclusion

In summary, the 30 52 10 oil seal is a vital component that offers significant advantages in various industries, particularly in automotive and machinery applications. By ensuring effective sealing of lubricants and preventing external contaminants from causing damage, oil seals play an integral role in the longevity and efficiency of mechanical systems. Understanding the specifications, materials, and applications of oil seals is crucial for anyone involved in product design, manufacturing, or maintenance, highlighting their importance in modern engineering practices.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories