Replacement Oil Seal for 25mm by 35mm Shaft Size in Various Applications

Understanding Oil Seals The 25x35x7 Specifications

Oil seals, also known as grease seals, are crucial components in various mechanical systems. They serve to prevent the leakage of lubricants while keeping contaminants from entering machinery. In this article, we will focus on a specific type of oil seal defined by the measurements 25x35x7 mm, exploring its applications, importance, and features.

What Do the Numbers Mean?

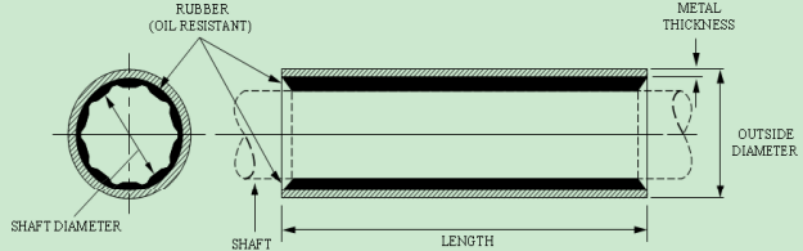

The designation 25x35x7 refers to the dimensions of the oil seal

- 25 mm This is the inner diameter (ID) of the seal. It fits snugly around a shaft or cylindrical surface. - 35 mm This is the outer diameter (OD) of the seal. It creates a seal against the housing or casing. - 7 mm This number indicates the thickness of the seal. A thicker seal usually suggests a more robust design capable of withstanding higher pressures.

These dimensions are crucial as they determine the seal’s fitting compatibility with the machinery. Ensuring the correct fit is vital to maintaining the equipment's efficiency and reliability.

Applications of 25x35x7 Oil Seals

Oil seals with these dimensions are commonly used in various industrial applications, including

1. Automotive One of the most prevalent uses of 25x35x7 oil seals is in vehicles. They can be found in transmission systems and engine components, preventing oil from leaking while keeping dirt and moisture out.

2. Industrial Machinery Many machines equipped with rotating shafts, such as pumps and motors, utilize these seals. With their ability to handle lubrication effectively, they enhance the longevity of the machinery by reducing wear and tear.

3. Agricultural Equipment Farming machinery, including tractors and harvesters, also employs these seals. Given the harsh conditions they operate in, robust seals are essential for maintaining functionality over time.

4. Construction Equipment Heavy machinery, like excavators and bulldozers, faces significant stress. Oil seals with the 25x35x7 specifications help contain lubricants in the hydraulic systems, ensuring smooth operation.

oil seal 25 35 7

Importance of Oil Seals

The role of oil seals in machinery cannot be overstated. Their primary function is to prevent leakage and contamination. Here are some key reasons why oil seals are important

- Lubrication Maintenance By containing the lubricant, oil seals ensure that internal parts remain lubricated, minimizing friction and wear. This is particularly important in systems where constant movement occurs.

- Contamination Prevention Keeping dirt, dust, and moisture out of machinery prevents unwanted wear and extends the life of internal components. A small amount of contamination can lead to significant damage over time.

- Improving Performance An effective oil seal leads to better operational efficiency. With proper lubrication and no contamination, machinery performs better and has a lower risk of breakdowns.

Features of High-Quality Oil Seals

When selecting oil seals, certain features contribute significantly to their effectiveness

- Material Oil seals are made from various materials, including rubber, polyurethane, and metal. Choosing the right material depending on the application and environment (such as temperature and exposure to chemicals) is crucial.

- Design Some oil seals come with additional features such as lip designs that enhance sealing capabilities. A dual-lip seal, for example, provides extra protection against contaminants.

- Durability The operational conditions dictate the required durability of an oil seal. High-quality seals can withstand varying pressures and temperatures, ensuring they last longer under demanding conditions.

Conclusion

In summary, the 25x35x7 oil seal is a small yet pivotal component in various machinery and automotive applications. Understanding its role and specifications helps in selecting the right seal for specific needs, ultimately enhancing operational efficiency and the longevity of equipment. Whether in vehicles, industrial machinery, or agricultural tools, the importance of oil seals cannot be underestimated. As technology progresses, advancements in seal materials and designs will continue to improve their performance, making them an integral part of modern mechanical systems. Proper maintenance and timely replacement of these seals are also essential to avoid costly repairs and ensure continuous operation.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories