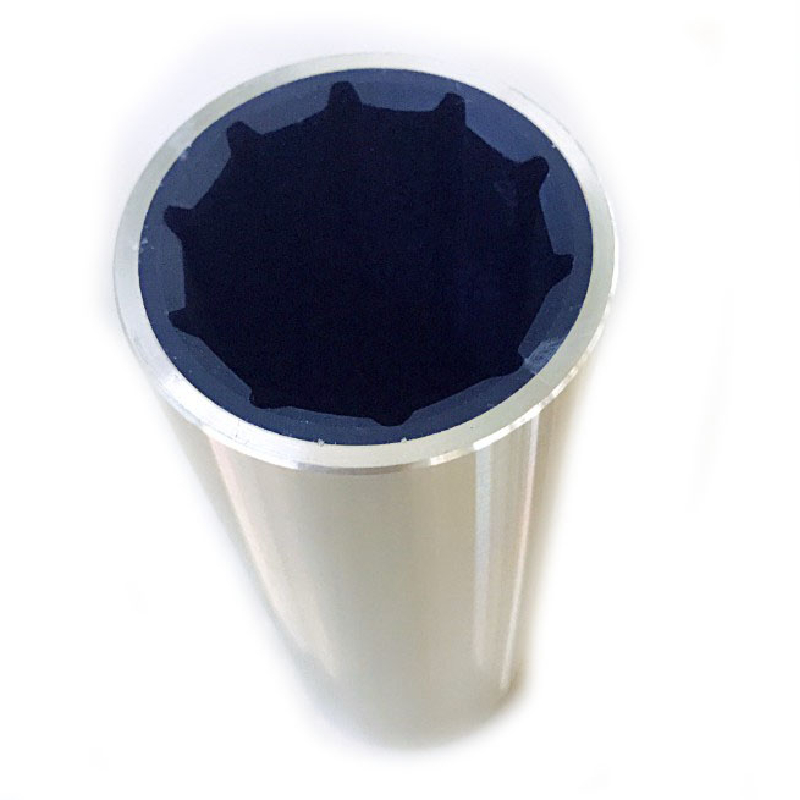

Engine Crankshaft Oil Seal 9031683001

When discussing expertise in this area, it's pivotal that experts highlight the subtle but significant differences in seal designs. For instance, the inclusion of a spring inside the seal can enhance its ability to maintain contact with the shaft under varying pressures, which is a common requirement in more robust industrial settings. Moreover, installation methodology can’t be overlooked. Even the highest quality seal can fail if improperly installed. Experts always recommend thoroughly cleaning the sealing area, ensuring no debris can compromise the integrity of the seal, and using appropriate tools to avoid distorting the seal during installation. From a trustworthiness standpoint, manufacturers of the oil seal 22 35 7 must adhere to strict production standards to ensure consistency and reliability. This commitment to quality is often validated by certifications and compliance with industrial standards, providing practitioners with peace of mind regarding the seal’s performance. Finally, it's critical for experts to remain abreast of evolving technologies in seal production, such as the development of new elastomer compounds that promise improved longevity and performance. Staying informed allows professionals to make data-driven decisions that elevate operational efficiency and machinery outcomes. In summary, the oil seal 22 35 7 might appear as a modest component, yet its role is indispensable in sustaining the seamless operation of numerous machines. With expertise, commitment to quality, and a focus on trustworthiness, these seals continue to support industries worldwide, serving as a testament to the significance of precision engineering in promoting mechanical efficacy.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories