High-Performance Oil Seal Specifications for 20x40x7 Applications

Understanding Oil Seals The 20 40 7 Specification

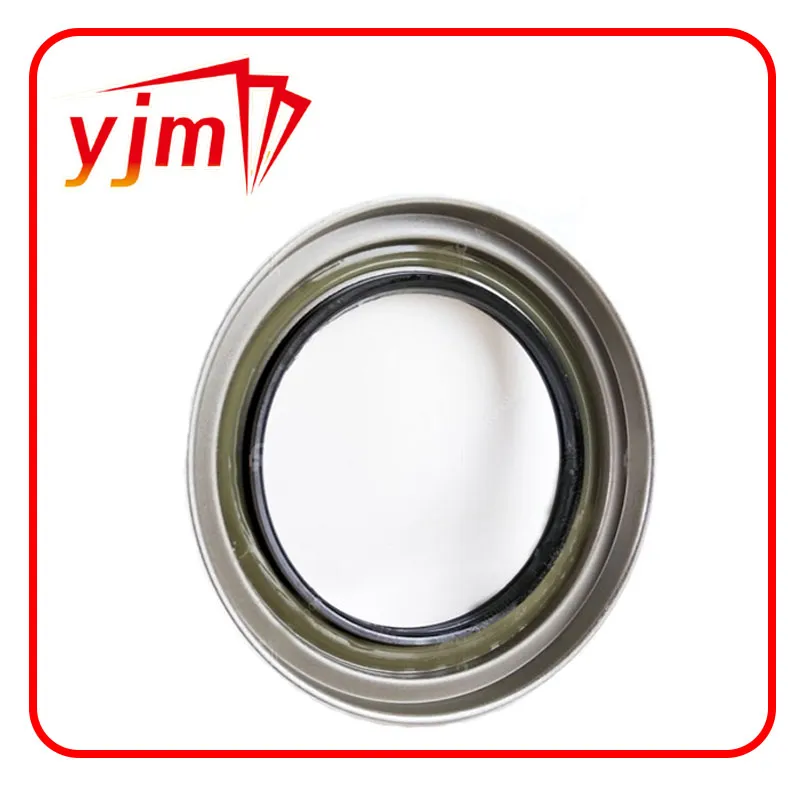

Oil seals, often referred to as lip seals or rotary shaft seals, are essential components in mechanical and automotive applications. Their primary function is to seal the interface between rotating and stationary parts, preventing the leakage of lubricants and entry of contaminants. Among the various sizes and specifications available, the 20 40 7 oil seal has garnered attention for its specific applications and benefits.

What Does 20 40 7 Mean?

The designation 20 40 7 provides important information about the dimensions of the oil seal. The first number, 20, indicates the inner diameter of the seal in millimeters, which means it is designed to fit onto a shaft or cylindrical surface with a diameter of 20 mm. The second number, 40, represents the outer diameter of the seal, which is 40 mm. The final number, 7, signifies the thickness of the seal, measuring 7 mm.

These dimensions are critical because they dictate the compatibility of the oil seal with various machinery and engine parts. Ensuring a proper fit is crucial for the effectiveness of the seal in preventing leaks and maintaining optimal operating conditions.

Applications of 20 40 7 Oil Seals

The 20 40 7 oil seals find use in a multitude of applications across different industries. Some common uses include

1. Automotive In vehicles, these oil seals are often used in engines and transmission systems. They help prevent oil leaks, ensuring that lubricants are contained within the moving parts, thereby improving efficiency and extending service life.

2. Industrial Machinery Many types of machinery, such as conveyor systems and construction equipment, rely on oil seals to retain lubricants and protect against dust and dirt. The 20 40 7 seals are well-suited for applications requiring reliable performance under varying pressures and temperatures.

oil seal 20 40 7

3. Agricultural Equipment Tractors and other farming machinery are exposed to harsh conditions. The robust design of oil seals, like the 20 40 7, ensures that they can withstand dust, moisture, and extreme temperatures commonly encountered in agricultural settings.

Benefits of Using Oil Seals

The advantages of using oil seals, particularly the 20 40 7 type, include

1. Leak Prevention The primary purpose of any oil seal is to prevent leaks. A properly fitted oil seal stops lubricants from escaping, which not only maintains necessary fluid levels but also prevents contamination of other components.

2. Extended Equipment Life By effectively sealing the lubricants, oil seals help reduce corrosion and wear on machinery parts. This leads to fewer breakdowns, less maintenance, and ultimately, a longer service life for the equipment.

3. Cost-Effectiveness Investing in quality oil seals can save money in the long run. By preventing leaks and reducing maintenance needs, businesses can avoid costly repairs associated with fluid loss and equipment failures.

4. Versatility Oil seals are available in varying materials and designs, accommodating a wide range of environmental conditions. The 20 40 7 specification can be selected in materials that withstand heat, chemicals, and ozone, enhancing durability.

Conclusion

In summary, the 20 40 7 oil seal serves a vital role in maintaining the integrity of various mechanical systems. Its specific dimensions cater to a variety of applications, particularly in the automotive and industrial sectors. By ensuring optimal sealing performance, these oil seals contribute to efficiency, reliability, and longevity of machinery. Understanding the specifications and applications of oil seals helps professionals choose the right components for their needs, leading to better operational success and reduced costs. Investing in quality oil seals is not just a matter of preventing leaks; it’s about fostering efficiency and reliability in every aspect of machinery operation.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories