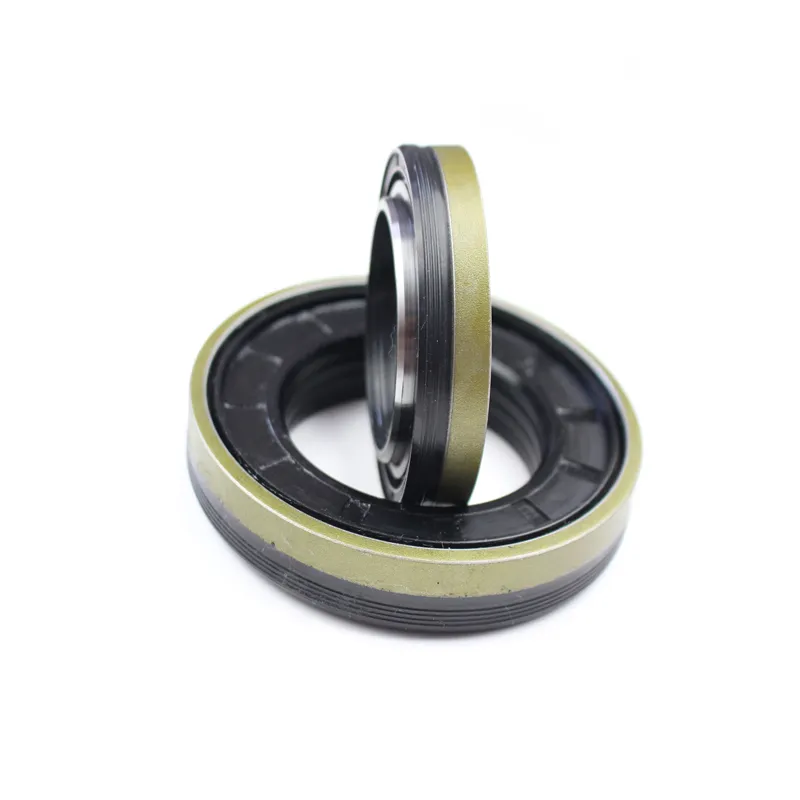

oil seal 170x200x15

Understanding the Oil Seal 170x200x15 A Key Component in Machinery

In the world of machinery and mechanical systems, oil seals play a crucial role in ensuring the smooth operation and longevity of equipment. One particular size that stands out in various applications is the oil seal 170x200x15. This specific size, measured in millimeters, is widely used across different industries due to its efficiency in preventing fluid leakage, which is essential for optimal machine performance.

What is an Oil Seal?

An oil seal, also known as a shaft seal or lip seal, is a device used to seal the space between stationary and rotating components in machinery. It is designed to keep lubricants in while preventing contaminants such as dirt, dust, and moisture from entering. This functionality is vital for maintaining the integrity of the lubrication system, which in turn reduces wear on moving parts and extends the lifespan of mechanical systems.

Specifications of Oil Seal 170x200x15

The designation 170x200x15 refers to the dimensions of the oil seal. The first number, 170, indicates the inner diameter (ID) of the seal, while the second number, 200, represents the outer diameter (OD). The third number, 15, signifies the width of the seal. With these specifications, the oil seal 170x200x15 is suitable for various shaft sizes and applications.

Typically made from durable materials such as rubber or synthetic rubber compounds, oil seals are designed to withstand a wide range of temperatures and pressures. The construction of these seals often includes a metal casing to provide added strength and stability, allowing them to maintain their shape and function effectively over time.

Applications of Oil Seal 170x200x15

oil seal 170x200x15

The oil seal 170x200x15 is commonly found in several applications, including automotive, industrial machinery, and agricultural equipment. In automotive contexts, these seals are essential for engine assemblies, transmission systems, and differential housings. They ensure that oil stays within these components, preventing leaks that could lead to significant damage and costly repairs.

In industrial settings, oil seals are crucial in hydraulic systems, gearboxes, and pumps. They protect against the loss of hydraulic fluid and ensure that machinery operates efficiently without unnecessary downtime. In agricultural machinery, oil seals contribute to the reliability of tractors, combines, and other equipment, where continuous operation in varied environmental conditions is essential.

The Importance of Quality

When it comes to oil seals, quality matters immensely. Choosing low-quality seals can lead to premature failure, resulting in oil leaks and overall machinery malfunctions. It is vital for procurement professionals and engineers to source seals from reputable manufacturers who adhere to industry standards. A quality oil seal will not only fit properly but will also perform under pressure, maintaining a seal that withstands the rigors of mechanical operation.

Installation and Maintenance

Proper installation of oil seals is critical to their performance. An incorrectly installed oil seal can lead to leaks and contamination. It is essential to follow manufacturer guidelines and utilize the right tools during installation. Additionally, routine maintenance checks should be conducted to inspect for signs of wear or damage, which can indicate the need for replacement. Early detection of issues can save time and money by preventing more substantial mechanical failures.

Conclusion

The oil seal 170x200x15 represents a small but vital component in the vast world of machinery. Its ability to prevent leaks and protect components is indispensable in various applications, from automotive engines to industrial machinery. By prioritizing quality and proper maintenance, businesses can ensure the longevity and efficiency of their equipment. Understanding the significance of this particular oil seal not only assists in choosing the right components but also contributes to the overarching goal of smooth and reliable machinery operation. Whether in manufacturing, automotive, or agricultural industries, the oil seal remains a cornerstone of effective design and engineering.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories