16x26x7 Oil Seal Specifications and Applications for Reliable Sealing Solutions

Understanding Oil Seals The 16x26x7 Specimen

Oil seals are crucial components in various mechanical systems, serving the primary purpose of containing lubricants and preventing the ingress of contaminants. Among the different types and sizes of oil seals available, the 16x26x7 oil seal stands out for its specific dimensions, which denote a seal with an inner diameter of 16 mm, an outer diameter of 26 mm, and a width of 7 mm. This article will explore the significance, design, applications, and benefits of the 16x26x7 oil seal.

Structure and Design

The design of an oil seal is integral to its function. The 16x26x7 oil seal typically comprises a circular rubber material that forms a lip, which presses against the shaft. This lip creates a tight seal to contain the lubricants—such as oil or grease—while effectively blocking dirt, dust, and other contaminants from entering the machinery. The choice of material is crucial; common materials include nitrile rubber (NBR), fluorocarbon rubber (FKM), and silicone rubber, each offering different properties suited for specific applications, such as temperature resistance and compatibility with various fluids.

Understanding Oil Seals The 16x26x7 Specimen

Oil seals, particularly the 16x26x7 variant, find extensive use in numerous applications. They are commonly employed in automotive components such as gearboxes, engines, and differentials. In the automotive sector, their role in preventing oil leakage is critical not only for maintaining the proper function of the machine but also for ensuring safety and efficiency. Beyond automotive uses, these seals are also prevalent in industrial machinery, hydraulics, and even household appliances. Their versatility makes them an essential component across various domains, including agriculture, aerospace, and manufacturing.

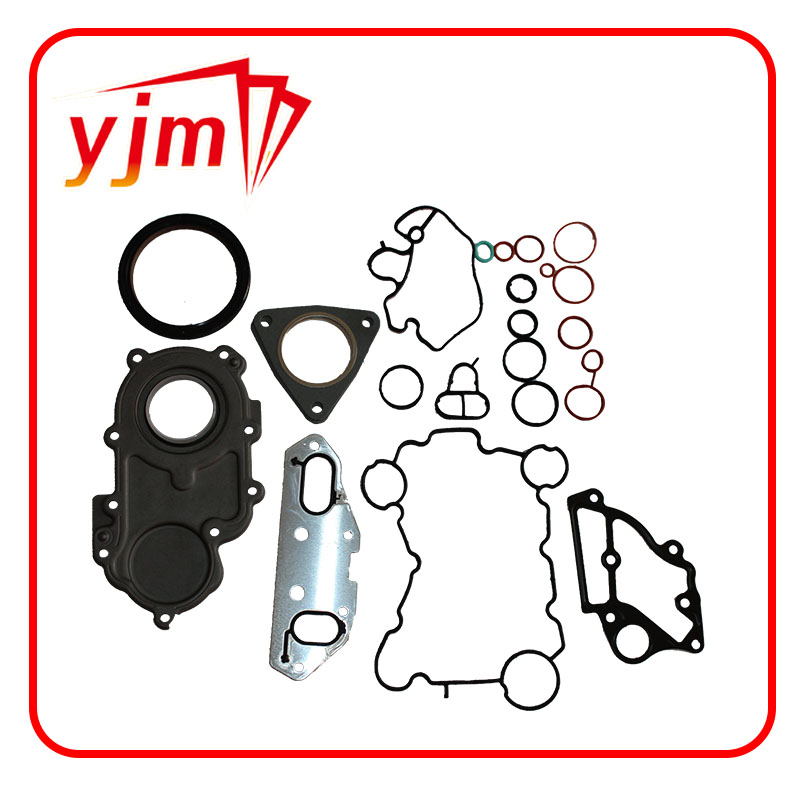

oil seal 16x26x7

Benefits of Using 16x26x7 Oil Seals

One of the primary benefits of the 16x26x7 oil seal is its ability to enhance the longevity and reliability of machinery. By effectively containing lubricants, these seals reduce the need for frequent maintenance and replacements, thus saving both time and operational costs. Furthermore, they help prevent contamination of the lubricant, which can lead to premature wear and tear of mechanical components.

Another significant advantage is the ease of installation. The standardization of the 16x26x7 size allows for simple replacement processes during maintenance. Mechanics and technicians can quickly identify the right seal, ensuring that downtime is minimized.

Moreover, many manufacturers design these seals to withstand high pressures and temperatures, making them suitable for high-performance applications. This resilience ensures that equipment operates optimally under challenging conditions, which is especially important in high-stakes industries like aerospace and telecommunications.

Conclusion

In conclusion, the 16x26x7 oil seal exemplifies the importance and functionality of oil seals in mechanical systems. Understanding its structure, design, and application provides insights into how these seemingly simple components contribute to the reliable operation of complex machinery. By preventing leaks and contamination, these seals play a vital role in enhancing efficiency, lowering maintenance costs, and prolonging the lifespan of equipment. As industries continue to evolve, the reliance on such essential components will only grow, reinforcing the need for quality oil seals like the 16x26x7 in our increasingly mechanized world.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories