automotive oil seal

The oil seal 140x170x15 aligns with global industry standards, an essential aspect that cannot be overlooked. Manufacturers who adhere to ISO certifications and other regulatory standards demonstrate a commitment to quality. These standards ensure that seals can withstand operational pressures, whether used in automotive, marine, or heavy machinery industries. Authoritativeness comes from a brand's history of performance and customer satisfaction, which is often reflected in their compliance with such rigorous standards. Trustworthiness in Performance Trust in an oil seal’s performance is built over time through consistent application outcomes. Anecdotal evidence from industry professionals attests to the reliability of the 140x170x15 oil seal. Its effectiveness in protecting bearings and other critical components from environmental contaminants has been validated in numerous case studies. Users frequently praise its ability to maintain operational efficiency without frequent replacements, instilling a sense of reliability that is paramount in operational planning and budgeting. Choosing the right oil seal is more than a selection; it’s an investment in your machinery’s future. While various factors, such as material and design, influence a seal's price, the cost is often recuperated through decreased downtime and extended machinery life. Seasoned engineers and maintenance professionals understand that opting for a trusted brand can make all the difference. In conclusion, the significance of an oil seal like the 140x170x15 extends beyond its physical dimensions. It embodies a blend of experience, expertise, authoritativeness, and trustworthiness, serving as a testament to the intricate balances in engineering. Selecting a suitable oil seal means entrusting a small yet vital peacekeeper with your machinery's integrity, ensuring operational efficiency and maintaining the health of critical components.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

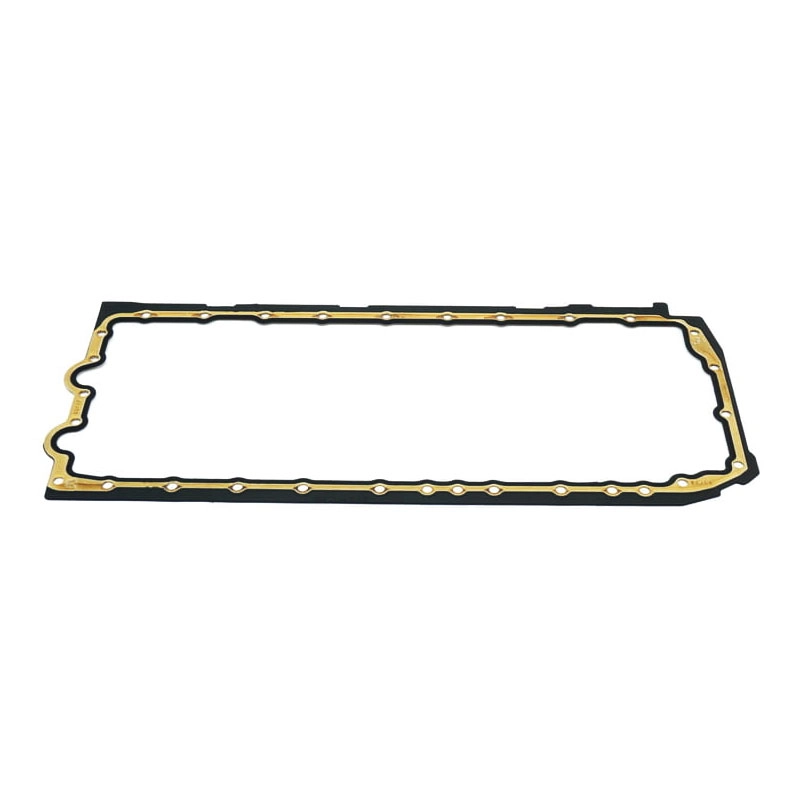

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories