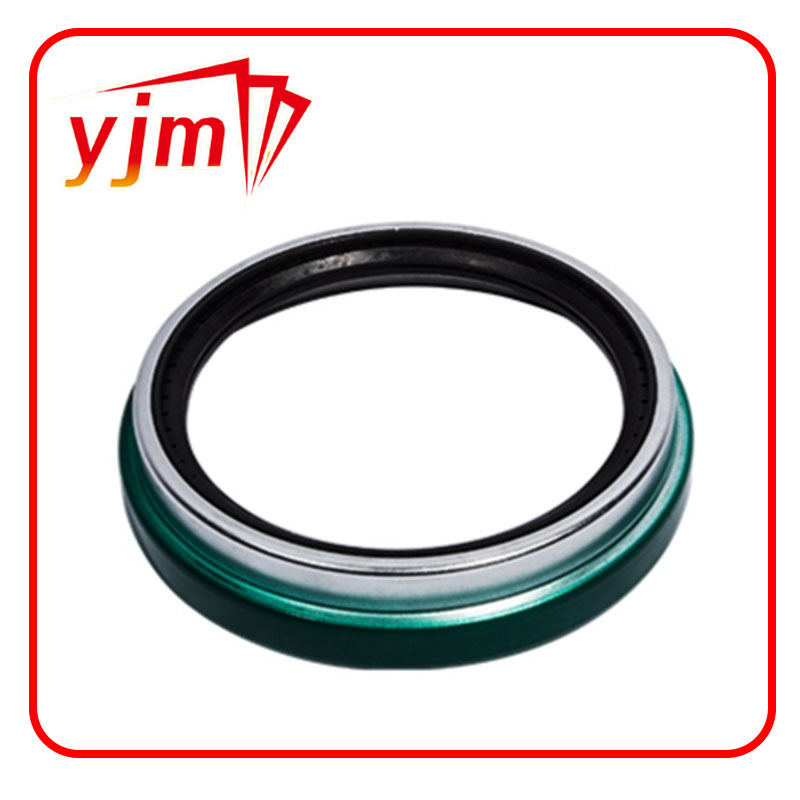

oil seal 130x160x12

Understanding Oil Seals A Focus on the 130x160x12 Specification

Oil seals, often referred to as shaft seals or lip seals, play a crucial role in various mechanical systems by preventing the leakage of lubricants. One particular specification that garners attention in the industry is the oil seal measuring 130x160x12 millimeters. This article will delve into the purpose, construction, applications, and selection of oil seals, specifically focusing on this defined size.

What is an Oil Seal?

An oil seal is a component that seals the connection between two parts of machinery, often where rotating shafts penetrate stationary housings. Its primary function is to prevent the loss of oil or lubricants while keeping out contaminants such as dust, dirt, and moisture. This is vital for maintaining the efficiency and longevity of mechanical systems. Oil seals ensure that the lubrication remains in the system, reducing friction and wear, which can lead to breakdowns and increased maintenance costs.

Dimensions of Oil Seal 130x160x12

The designation 130x160x12 refers to the dimensions of this specific oil seal. The first number, 130 mm, represents the inner diameter (ID), which fits snugly around a shaft. The second number, 160 mm, indicates the outer diameter (OD), which fits into the housing. Lastly, 12 mm refers to the thickness of the seal. The precise sizing is critical because it ensures a proper fit, which is essential for effective sealing.

Construction and Materials

Oil seals typically consist of several key components a rubber or elastomeric sealing lip, a body, and sometimes a spring. The sealing lip is the primary element that forms a barrier against oil leakage. This lip is usually made from various materials, including nitrile rubber, silicone, or fluorocarbon elastomers, each chosen based on the conditions under which the seal will operate (temperature, pressure, and chemical exposure).

Among the materials, nitrile rubber is commonly used for its excellent resistance to petroleum-based oils and its good aging properties. Silicon rubber can withstand higher temperatures and is generally used in more demanding environments. Fluorocarbon materials (e.g., Viton) offer resistance to aggressive chemicals and extreme temperatures but may be more costly.

Applications of 130x160x12 Oil Seals

oil seal 130x160x12

The 130x160x12 oil seal has a variety of applications in different industries. Common uses include

1. Automotive Engineering Oil seals are essential in vehicle engine assemblies, automatic transmissions, and differential housings to prevent oil leakage and ensure the efficient functioning of components.

2. Manufacturing Equipment In industrial machinery, oil seals are used to protect bearings and gears, enhancing equipment reliability and minimizing downtime.

3. Pumps and Compressors These seals are critical in pumps and compressors, where they keep the lubricants contained and ensure that external contaminants do not interfere with the operation.

4. Agricultural Machinery Heavy machinery used in agriculture also relies on effective oil seals to maintain their performance under severe working conditions.

Selecting the Right Oil Seal

Choosing the correct oil seal is essential for optimal performance. Here are key factors to consider

- Shaft and Housing Size The dimensions must match precisely, as indicated by the 130x160x12 specification. - Material Compatibility The selected material should withstand the operating environment, including temperature fluctuations and chemical exposure. - Operating Conditions Understand the conditions where the seal will function, including speed, pressure, and potential contaminants. - Seal Design There are various designs, such as single-lip or double-lip seals, which may be suited depending on the application.

Conclusion

Oil seals such as the 130x160x12 specification are integral to a plethora of mechanical systems across different industries. They prevent lubricant loss and keep contaminants at bay, ensuring smooth and efficient operation. When selecting oil seals, it’s vital to consider the application's unique characteristics to avoid failure and extend the lifespan of machinery. Understanding these aspects can significantly contribute to better maintenance practices and improved operational efficiency in various applications.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories