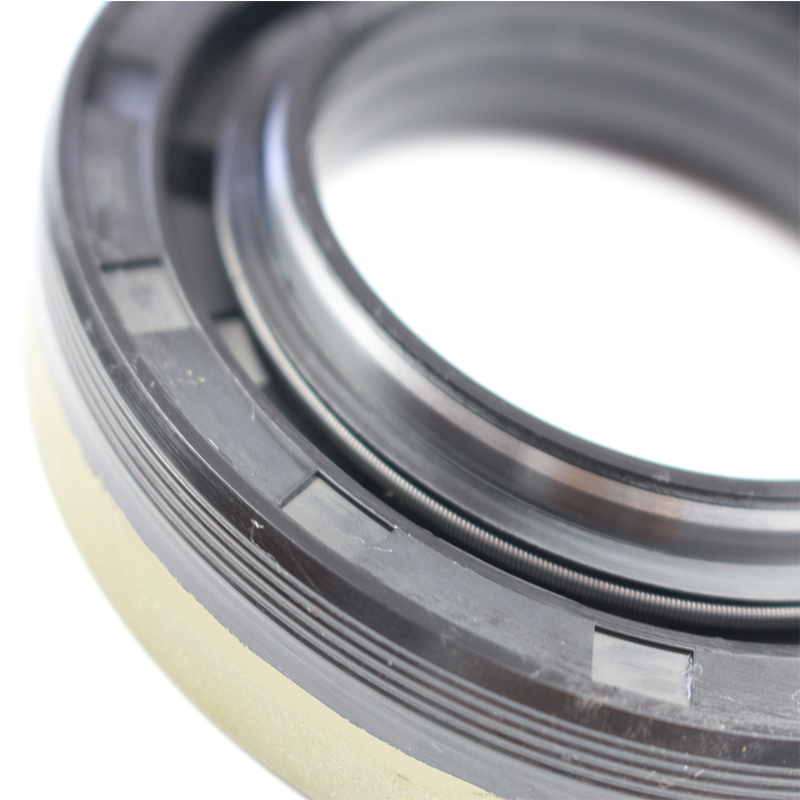

oil seal 100x120x12

Authority in the Marketplace The market authority of this oil seal size stems from its widespread adoption and proven efficacy. Numerous manufacturers across the globe conform to this specification, producing seals that consistently meet or exceed industry standards. Its adoption is a testament to the seal’s engineered reliability, with companies specifying it as a component in their OEM setups. Its prevalent use in diverse settings, from high-speed axles to turbines, bolsters its reputation. Certification standards for these oil seals, including ISO certifications, also lend a layer of trust and authority, affirming that the product aligns with rigorous quality controls. Such credentials reassure end-users of their investment in a component that is both reliable and optimal for demanding applications. Trustworthiness in Product Choice Trust is a non-negotiable factor in product choice within industrial contexts. The oil seal size 100x120x12, due to its robust material composition, has earned a reputation for reliability. For maintenance professionals and engineers, selecting these oil seals translates to peace of mind, knowing that they are using components that are less prone to premature failure. Trust is further reinforced through detailed product data sheets and installation guides provided by manufacturers, offering precise details on operating limits, expected life cycles, and compatibility. These documents are instrumental in educating users on best practices for installation and maintenance, ensuring that the oil seal delivers expected outcomes. In summary, the oil seal 100x120x12 serves as an exemplar of how small components can have substantial impacts on mechanical systems. Through practical experience, expertise in functionality, market authority, and trustworthiness, it stands as a critical piece that supports the seamless operation of complex machinery. Such oil seals are not merely parts of mechanical systems but rather key contributors to their sustainability and longevity.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories