O-Ring Replacement Guide for Oil Pump Maintenance and Efficiency Improvements

The Importance of Oil Pump O-Rings in Engine Performance

When it comes to the efficiency and longevity of an engine, many components play crucial roles. Among these is the oil pump, a pivotal element that ensures proper lubrication throughout the engine's moving parts. However, one often overlooked yet essential part of the oil pump is the O-ring. This small, circular component is vital for maintaining optimal oil flow, preventing leaks, and ensuring the overall performance of the engine.

Understanding O-Rings and Their Function

An O-ring is a simple, doughnut-shaped piece made from elastomeric materials such as rubber, silicone, or fluorocarbon. Its primary function is to create a seal between two components, in this case, the oil pump and the engine block. By forming a tight seal, the O-ring prevents oil from leaking out and helps maintain the necessary pressure within the oil system. This is particularly important because the oil pump operates under varying temperatures and pressures, which can lead to the deterioration of weaker seals.

The significance of the O-ring becomes even more apparent when we consider the consequences of a faulty seal. A compromised O-ring can result in oil leaks, which not only reduce the engine’s lubrication effectiveness but can also lead to catastrophic engine failure. Without adequate lubrication, friction between engine components can increase, resulting in overheating and extensive damage. Thus, the O-ring plays an essential role that goes far beyond its size.

Common Issues with O-Rings

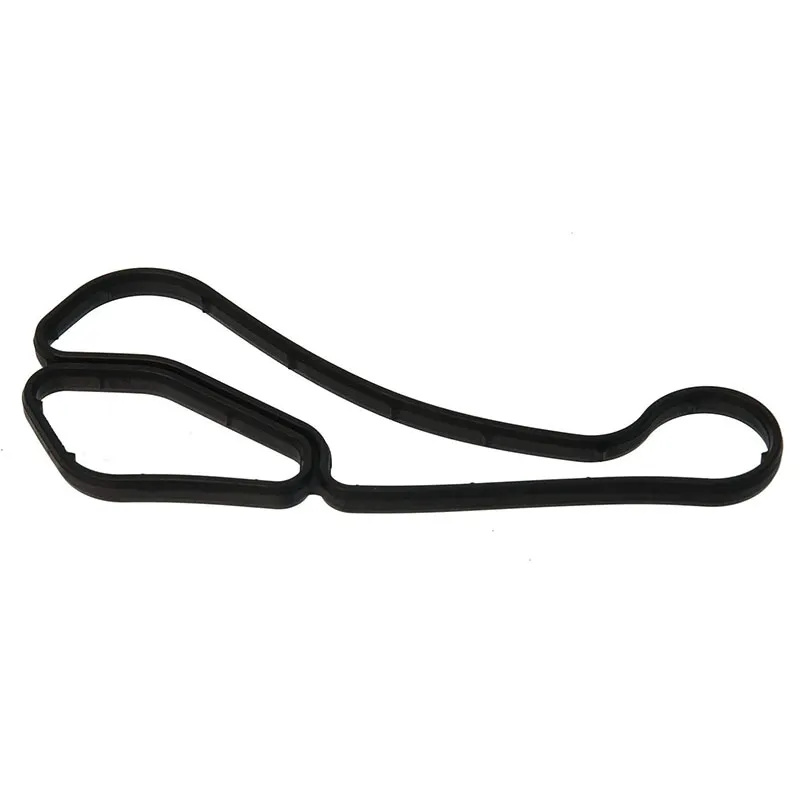

oil pump o ring

Over time, O-rings can degrade due to a variety of factors. Exposure to extreme heat, pressure, and corrosive substances can cause the material to harden, crack, or lose elasticity. When this happens, the O-ring may begin to fail, resulting in oil leaks. Regular maintenance and timely replacement of O-rings are crucial for ensuring that the oil pump operates efficiently and the engine remains in good condition.

In addition to the physical wear and tear on O-rings, there are other contributing factors to seal failure. For instance, improper installation can lead to misalignment, which compromises the O-ring’s ability to create a tight seal. Ensuring that O-rings are correctly installed and adequately lubricated during assembly is vital for their longevity. This highlights the importance of having qualified technicians perform maintenance on engines, as they possess the knowledge and skills to handle these components properly.

Selecting the Right O-Ring

When it comes to replacing an O-ring, selecting the correct type is essential. Different engines may require O-rings made from specific materials that can withstand particular temperatures and pressures. Using the wrong O-ring can have detrimental effects on the engine's performance. For instance, a material that cannot handle high temperatures may soften over time, leading to premature failure. Therefore, always consult the manufacturer’s specifications or seek professional assistance when selecting replacement O-rings.

Conclusion

In conclusion, O-rings might be small, but they play a monumental role in the overall health and performance of an engine. The oil pump, while larger and more complex, depends heavily on the integrity of its O-ring seal. Ensuring that these components are regularly checked, properly installed, and maintained can prevent costly repairs and extend the life of the engine. Whether you are a seasoned mechanic, a car enthusiast, or an everyday driver, remembering the significance of these seemingly minor parts can make a substantial difference in engine operation. Investing a little time and attention to the oil pump O-ring can yield significant dividends in performance, efficiency, and reliability.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories