Choosing the Right Oil Pan Washer for Efficient Automotive Maintenance

Understanding the Importance of Oil Pan Washers

The oil pan washer may seem like a small and often overlooked component in the automotive industry, but its significance in ensuring the proper functioning of an engine cannot be understated. This article will delve into what oil pan washers are, their functions, and why they are critical for the longevity and performance of an engine.

What is an Oil Pan Washer?

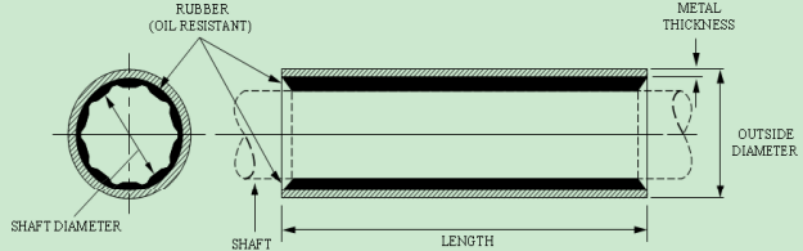

An oil pan washer is a flat, typically round gasket or sealing ring that is placed between the oil pan and the engine block. When the oil pan is bolted onto the engine, the washer creates a seal that prevents engine oil from leaking out. These washers are usually made of various materials, including metal, rubber, or composite materials, depending on the specific requirements of the engine and its operating conditions.

Functions of Oil Pan Washers

1. Leak Prevention The primary function of an oil pan washer is to prevent leaks. Engine oil is crucial for lubricating moving parts within the engine. If oil begins to leak due to a faulty or worn washer, it can lead to a significant loss of lubrication, resulting in increased friction, overheating, and ultimately, potential engine failure.

2. Vibration Dampening Engines generate a considerable amount of vibration during operation. Oil pan washers help absorb some of this vibration, which can protect both the oil pan and the engine block from wear and tear over time.

3. Thermal Expansion Compensation Engines operate under varying temperature conditions. The oil pan washer accommodates for thermal expansion and contraction of the engine parts, helping to ensure a consistent and effective seal even as components heat up or cool down.

oil pan washer

Importance of Quality Oil Pan Washers

Using high-quality oil pan washers is crucial for achieving optimal engine performance. When replacing these washers, it is essential to choose the right type that is specifically designed for the engine in question. Generic or subpar washers may not provide a proper seal, leading to leaks and potential engine damage.

Additionally, the installation process is vital. A properly installed oil pan washer can make the difference between a successful seal and a leaking oil pan. It is recommended to clean the mating surfaces thoroughly before installation and to torque the bolts to the manufacturer’s specifications to ensure the best seal possible.

Signs of a Worn Oil Pan Washer

Over time, oil pan washers can degrade due to factors such as temperature fluctuations, exposure to engine oil, and the mechanical stress of the engine. Recognizing the signs of a worn or failing washer is vital for immediate corrective action. Common indicators include

- Oil Spots or Puddles If you notice oil spots or puddles beneath your vehicle, it may indicate a leak from the oil pan. - Low Oil Levels Regularly checking oil levels can help catch leaks early. A sudden drop in oil levels might suggest a faulty washer. - Engine Noise Unusual noises from the engine might indicate lubrication issues due to insufficient oil levels.

Conclusion

In conclusion, oil pan washers are a small but critical component of engine assembly that plays a significant role in maintaining the health and efficiency of an engine. By preventing leaks, absorbing vibrations, and compensating for thermal expansion, they ensure that the engine operates smoothly and safely. Regular maintenance and timely replacement of these washers can prevent severe engine damage and extend the life of the vehicle, making it essential for vehicle owners and mechanics to prioritize this often-overlooked part of automotive care. In the realm of automotive maintenance, attention to detail can save significant costs and prevent larger issues down the road.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories