Oil Pan Screw Replacement Guide for Enhanced Vehicle Performance and Longevity

Understanding Oil Pan Screws Importance and Functionality

Oil pan screws are small yet crucial components of an automobile's engine assembly. These screws play an essential role in securing the oil pan, which houses the engine oil necessary for lubrication, cooling, and proper functioning of the engine's components. Although they may seem inconspicuous, the significance of oil pan screws cannot be overlooked, as they contribute to the overall reliability and efficiency of the engine.

Function of Oil Pan Screws

The primary function of oil pan screws is to maintain the integrity of the oil pan by securely fastening it to the engine block. The oil pan, often made of aluminum or stamped steel, serves as a reservoir for oil, collecting it after it has circulated through the engine. When the engine operates, oil is drawn from the pan, circulated to vital components, and then returned to the pan. Any leak or breach in this system can lead to significant oil loss, resulting in engine overheating or catastrophic failure.

Oil pan screws are designed to withstand the harsh conditions of the engine environment. These screws are typically made from high-strength materials, such as steel or stainless steel, which can endure exposure to high temperatures and corrosive engine oils. Additionally, the screws are often treated with anti-corrosive coatings to enhance their durability and lifespan.

Types of Oil Pan Screws

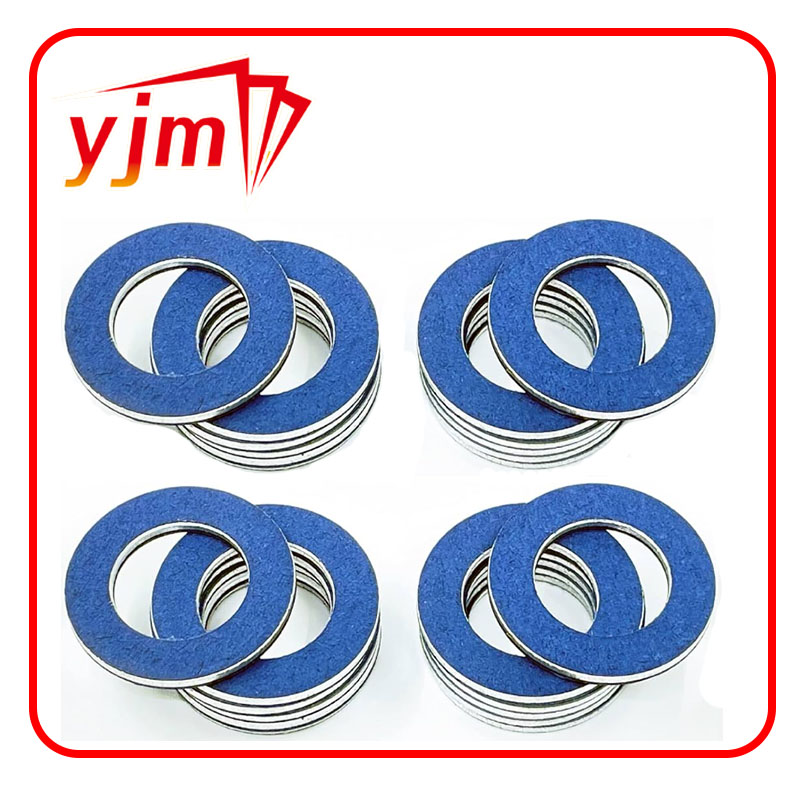

oil pan screw

There are various types of oil pan screws, each suited for specific applications. The most common types include hex head screws, socket cap screws, and flange screws. Hex head screws, recognizable by their hexagonal shape, are often used for their ease of installation and removal with standard tools. Socket cap screws provide a stronger grip and are advantageous in tight spaces, while flange screws feature a built-in washer that distributes load evenly, reducing the risk of deformation.

Importance of Proper Installation

When it comes to oil pan screws, proper installation is crucial. Over-tightening the screws can lead to warping of the oil pan, which can create leaks, while under-tightening can result in insufficient sealing, allowing oil to seep out. It is essential to follow the manufacturer’s specifications for torque settings during installation to ensure the optimal performance of the oil pan and its screws.

In emergencies, if an oil pan screw is stripped or damaged, it can lead to oil leaks that must be addressed immediately. Tools such as thread repair kits may assist in restoring the screw hole, allowing for the re-installation of a new oil pan screw. Regular inspection of the oil pan and its screws is advisable, particularly in older vehicles or those with high mileage.

Conclusion

In summary, oil pan screws may be small, but their importance in vehicle maintenance and engine performance is significant. They not only secure the oil pan but also ensure that the critical engine oil remains contained, allowing the engine to function optimally. As with many components in an engine, regular checks and adherence to proper installation practices can help maintain the longevity and efficiency of the vehicle. Understanding the role and significance of these screws can empower vehicle owners and mechanics alike to make informed decisions, ultimately contributing to safer and more reliable automotive operation.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories