Understanding the Importance of Oil Pan O-Ring in Engine Performance and Maintenance

Understanding the Importance of Oil Pan O-rings in Engine Performance

When it comes to maintaining optimal engine performance, the oil pan is a crucial component that often goes unnoticed. The oil pan serves as a reservoir for engine oil, allowing it to circulate through the engine's vital parts. However, one small yet significant element associated with the oil pan is the O-ring. The oil pan O-ring plays an essential role in ensuring that the engine remains lubricated and free from leaks.

What is an Oil Pan O-ring?

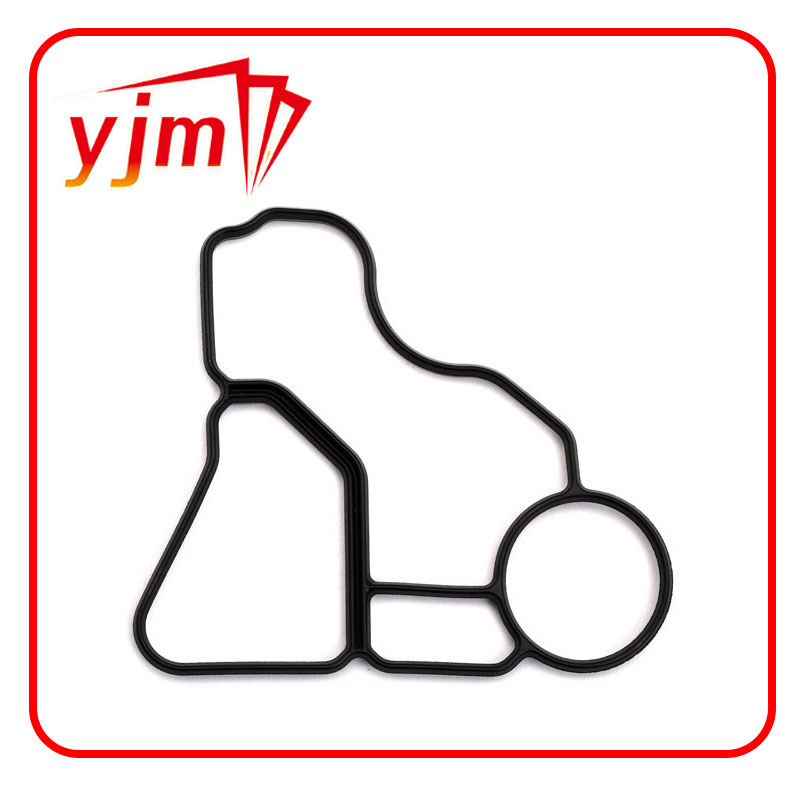

An oil pan O-ring is a circular seal made of rubber or silicone that is designed to create a watertight barrier between the oil pan and the engine block. This seal is critical for preventing oil leaks, which can lead to substantial engine damage if left unchecked. A good O-ring ensures that the oil stays contained within the pan, allowing for efficient lubrication of moving engine parts.

Importance of a Proper Seal

The oil circulating through the engine is responsible for lubrication, cooling, and cleaning interior components. If oil leaks due to a worn or damaged O-ring, the oil level can drop, leading to insufficient lubrication. Insufficient lubrication may cause increased friction among engine parts, which can result in overheating and ultimately cause the engine to seize.

Moreover, an oil leak can create significant environmental concerns, as leaked oil can contaminate soil and waterways. Additionally, oil stains on driveways or garage floors can reduce the aesthetic appeal of our living spaces. Thus, ensuring the O-ring is in good condition is essential for both engine health and environmental responsibility.

Signs of a Failing O-ring

As with many parts in the vehicle, O-rings can wear out over time

. There are several signs that may indicate a failing oil pan O-ringoil pan o ring

1. Oil Leaks The most obvious sign of a damaged O-ring is the presence of oil puddles or stains beneath the vehicle. If you notice a persistent oil leak, it is advisable to inspect the oil pan and O-ring for any signs of wear or damage.

2. Low Oil Levels Regularly checking the engine oil level is crucial. If you notice a drop in oil levels despite regular refills, the O-ring may be the culprit.

3. Check Engine Light In some vehicles, a failing O-ring can trigger the check engine light. If this warning light appears, it is worth examining the oil pan and its seals.

Replacement of the O-ring

If you discover that your oil pan O-ring is damaged or worn out, replacing it is generally a straightforward process but does require some mechanical skills. Here’s a brief outline of the steps involved

1. Drain the Oil First, drain the engine oil to avoid any spills. 2. Remove the Oil Pan Depending on your vehicle, this may require removing several bolts and brackets. 3. Replace the O-ring Remove the old O-ring and clean the surfaces. Then, place the new O-ring in its intended groove. 4. Reattach the Oil Pan Carefully position the oil pan back onto the engine block and resecure it with bolts. 5. Replenish Engine Oil Finally, refill the engine oil to the appropriate level.

It is essential to select a high-quality O-ring that is compatible with your specific vehicle make and model. Inferior-quality seals can lead to early failure and more frequent replacements.

Conclusion

In conclusion, the oil pan O-ring may seem like a small component, but its role in engine performance is vital. A proper seal protects against oil leaks and ensures that the engine operates smoothly. Regular maintenance and inspection can prevent the problems that arise from a failing O-ring, safeguarding your vehicle against costly repairs and environmental damage. Always remember that the health of your engine begins with small but significant parts like the oil pan O-ring.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories