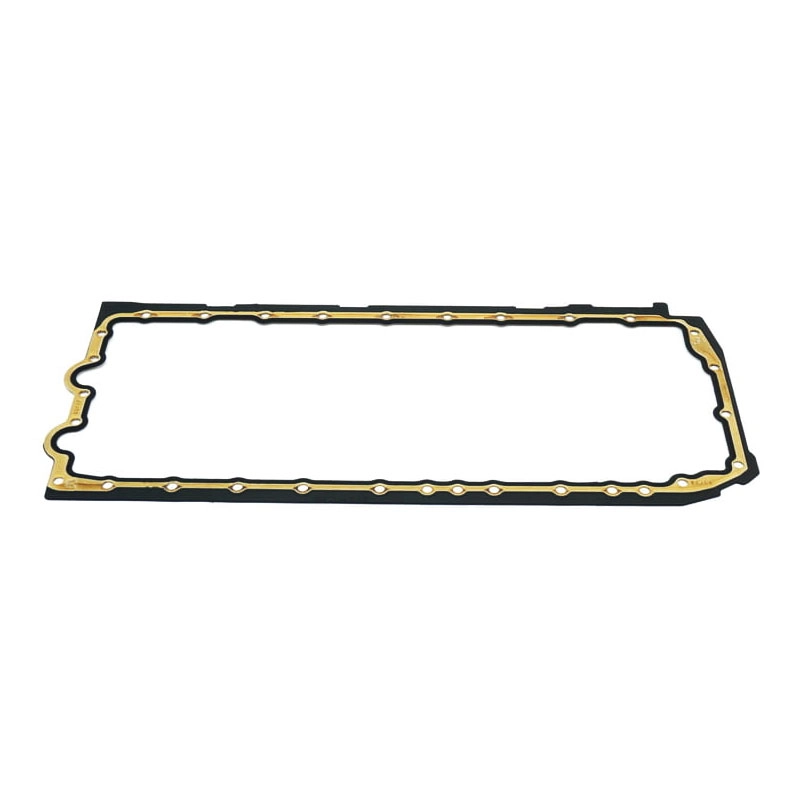

oil pan gasket material

Understanding Oil Pan Gasket Materials

The oil pan gasket plays a crucial role in any internal combustion engine, sealing the oil pan to the engine block and preventing oil leaks. Given its importance, selecting the right material for the oil pan gasket is vital for the engine's performance and longevity. Various materials are employed in the manufacturing of oil pan gaskets, each with its own set of characteristics that influence durability, resistance to temperature fluctuations, and compatibility with engine oils.

Understanding Oil Pan Gasket Materials

In modern applications, synthetic materials have become increasingly popular for oil pan gaskets. These include rubberized compounds and silicone-based materials. Rubber gaskets are highly flexible and can withstand various temperatures, making them ideal for the dynamic environment of an operating engine. Silicone gaskets, in particular, excel in high-temperature applications, maintaining their integrity even when exposed to excessive heat. Additionally, silicone creates a robust sealing surface that can resist oil and other fluids, extending the period before replacement becomes necessary.

oil pan gasket material

Another innovative material used in oil pan gaskets is polyurethane. Recognized for its superior chemical resistance, polyurethane gaskets provide a reliable seal while maintaining flexibility. Their resilience against both heat and oil degradation makes them an excellent choice for modern engines that operate under stringent conditions.

The choice of gasket material can also be influenced by the specific engine design and manufacturer recommendations. Some manufacturers may prefer particular materials based on their engine's unique engineering characteristics and performance requirements. For instance, high-performance engines that operate at elevated temperatures may benefit from advanced materials like multi-layer steel (MLS) gaskets, which offer enhanced sealing capabilities.

In conclusion, the selection of oil pan gasket materials is critical for ensuring optimal engine performance and longevity. Traditional options like cork and fiber have evolved into advanced synthetic materials such as rubber, silicone, and polyurethane, each providing distinct advantages. Understanding these materials enables engineers and mechanics to make informed decisions that promote engine efficiency and reliability, ultimately leading to a smoother and longer-lasting driving experience.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories