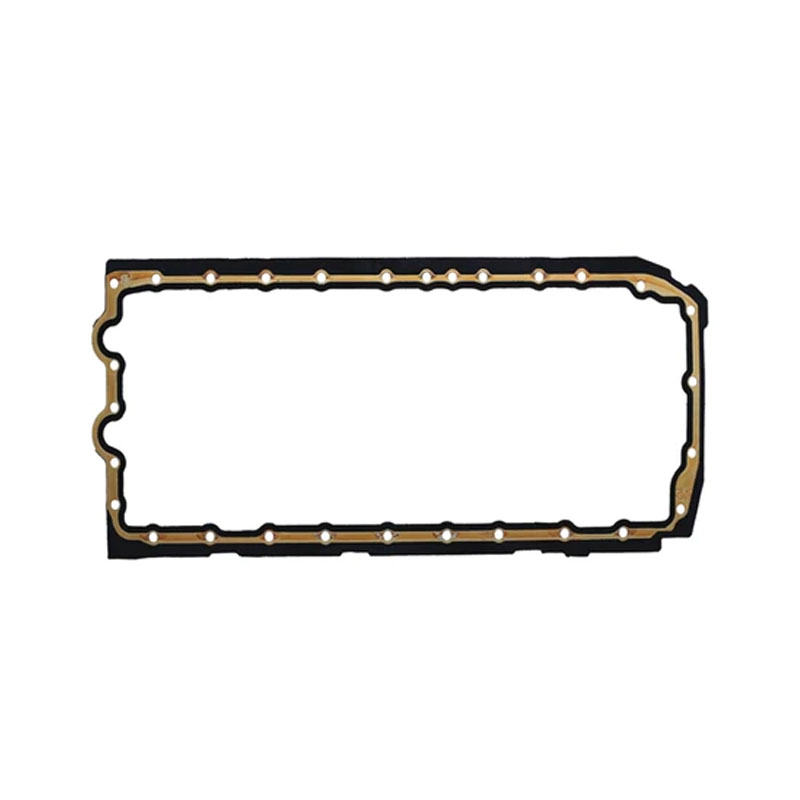

oil housing seal

Understanding Oil Housing Seal Importance and Applications

Oil housing seals play a critical role in various mechanical systems, particularly in automotive and industrial applications. These seals are crucial because they help retain oil within the housing, preventing leaks that can cause significant damage to machinery. The importance of oil housing seals cannot be understated, especially in environments that require precision and reliability.

What is an Oil Housing Seal?

An oil housing seal is a type of sealing device designed to prevent the escape of lubricating oil from a housing, ensuring that the machinery continues to operate smoothly. Typically made from materials such as rubber, felt, or polyurethane, these seals are engineered to withstand high pressures and temperatures while providing effective sealing capabilities. They are commonly used in engines, gearboxes, and other mechanical assemblies where oil is essential for lubrication.

The Importance of Oil Housing Seals

1. Preventing Oil Leaks The primary function of oil housing seals is to prevent the leakage of oil from the housing. Oil leaks can lead to various problems, including reduced lubrication efficiency, increased friction, overheating, and potential engine failure. By ensuring that the oil remains contained, these seals help maintain the integrity and functionality of the system.

2. Extending Equipment Lifespan Proper sealing contributes to the overall longevity of machinery. By reducing oil leaks, oil housing seals prevent wear and tear on components caused by inadequate lubrication. This, in turn, helps avoid costly repairs and extends the lifespan of the equipment.

3. Environmental Protection Oil leaks can have serious environmental consequences. They can contaminate soil and water sources, leading to ecological damage. By effectively sealing oil within the housing, these seals not only protect the machinery but also safeguard the environment from potential harm.

4. Enhancing Performance A well-functioning oil housing seal can enhance the overall performance of a mechanical system. By ensuring that the lubricating oil remains in place, these seals allow for optimal oil flow, which is vital for maintaining the proper temperature and function of the machinery.

oil housing seal

Types of Oil Housing Seals

There are several types of oil housing seals, each designed for specific applications. The most common include

- Lip Seals These seals are designed with a lip that faces the lubricating oil. They are particularly effective in preventing leaks in rotating shafts, such as those found in engines and gearboxes.

- O-Ring Seals O-rings are circular seals that provide a tight fit between two surfaces. They are versatile and commonly used in various industries, including automotive and aerospace.

- Gaskets Gaskets serve as seals between two rigid surfaces to prevent leakage. They are often used in conjunction with oil housing seals to provide a comprehensive sealing solution.

Maintenance and Replacement

To ensure the longevity and effectiveness of oil housing seals, regular maintenance is essential. Signs of wear or damage should be addressed promptly. Common indicators that a seal needs replacement include visible oil leaks, unusual noises from the machinery, or overheating components.

In conclusion, oil housing seals are vital components in mechanical systems, providing essential functions such as preventing leaks, protecting the environment, and enhancing overall performance. Understanding the types of seals and their importance can help in the maintenance and repair of machinery, ensuring optimal operation and durability. Whether in automotive applications or industrial machinery, these seals play a crucial role in the successful functioning of complex systems. Proper attention to oil housing seals can lead to a more efficient, sustainable, and functional operation.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories