High-Performance Oil Bolt Washers for Enhanced Sealing and Durability in Mechanical Applications

Understanding Oil Bolt Washers Their Importance and Functionality

In the world of machinery and automotive engineering, seemingly small components often play a crucial role in the overall performance and safety of a system. One such component that often goes unnoticed yet serves a vital function is the oil bolt washer. Although they may appear as simple discs made of various materials, their significance cannot be overstated.

What is an Oil Bolt Washer?

An oil bolt washer is a type of washer specifically designed to be used with bolts in applications related to oil systems, such as engines and hydraulic systems. These washers are typically placed between the bolt head and the surface of the material being fastened. Their primary purpose is to create a seal that prevents oil from leaking out of the joint, while also distributing the load of the bolt more evenly, which helps to prevent damage to the surfaces they are securing.

Materials Used

Oil bolt washers come in various materials, each suited for different applications depending on the requirements for temperature, pressure, and chemical compatibility. Common materials include

1. Rubber Often used for its excellent sealing capabilities, rubber washers are ideal for low-pressure oil applications. They are flexible and can accommodate slight irregularities in the surface they are sealing against.

2. Metal Washers made from metal, such as steel or aluminum, are typically used in high-pressure applications. They provide durability and strength but may require additional sealing compounds to prevent leaks.

3. Composite Materials Some washers are made from composite materials that combine the advantages of rubber and metal, providing both flexibility and resistance to pressure and temperature variations.

The Importance of Proper Installation

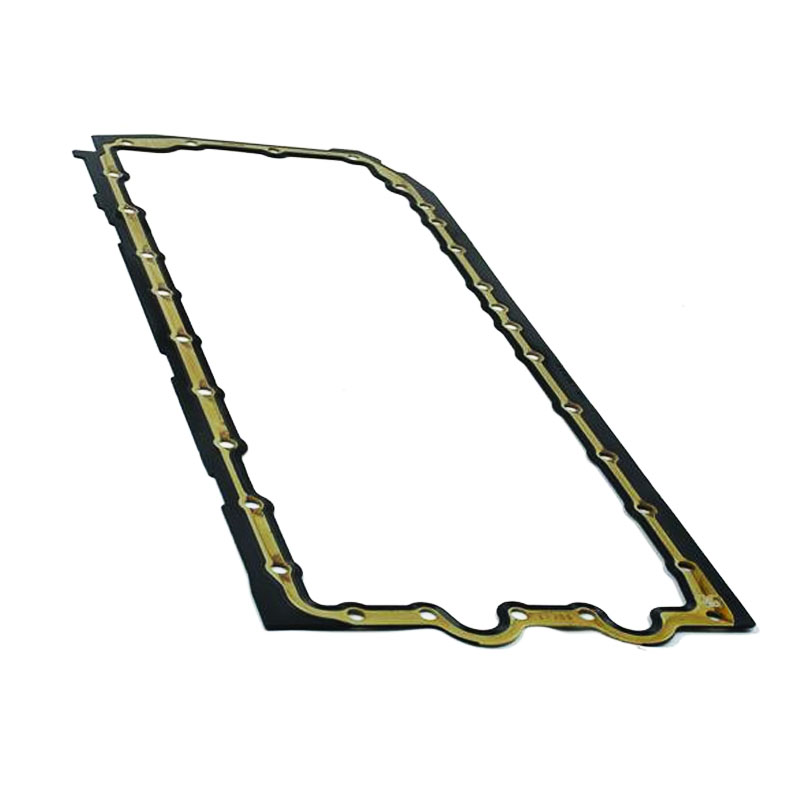

oil bolt washer

The effectiveness of an oil bolt washer depends heavily on its correct installation. When installing, it's essential to ensure that the surfaces being joined are clean and free of debris. Any contaminants can compromise the integrity of the seal. The bolt must also be torqued to the manufacturer's specifications; overtightening can compress the washer too much, leading to deformation and potential failure, while insufficient torque can result in leaks.

Common Applications

Oil bolt washers are used in a wide range of applications, including

- Automotive Engines They are crucial in holding components like oil pans, cylinder heads, and other engine parts securely while preventing oil leaks, which could lead to serious engine damage.

- Hydraulic Systems In hydraulic machinery where fluids are under high pressure, these washers help maintain system integrity by preventing fluid leaks at connection points.

- Industrial Equipment Many pieces of industrial machinery also utilize oil bolt washers to ensure operational safety and efficiency.

Maintenance and Replacement

Regular maintenance is vital for systems that utilize oil bolt washers. Inspecting for leaks should be a routine practice, especially in vehicles and heavy machinery. If leaks are detected, it's often a sign that the washer may be damaged and needs to be replaced. Additionally, upon reassembling components, it's advisable to replace the washers, as wear and tear can compromise their sealing capabilities.

Conclusion

Though often overlooked, oil bolt washers are an integral part of mechanical systems that handle oil and hydraulic fluids. The selection of appropriate materials, correct installation, and routine maintenance ensure that these small components effectively contribute to the overall reliability and safety of engines and machinery. As engineers and mechanics continue to innovate and improve machinery designs, the importance of such seemingly minor components will remain significant, underscoring the idea that in engineering, the smallest details often have the largest impact.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories