Selecting the Right Size for Oil Bolt Applications and Installations

Understanding Oil Bolt Size Importance and Specifications

When it comes to machinery and automotive applications, the significance of oil bolt size is often overlooked yet plays a crucial role in the overall functionality and reliability of mechanical systems. Oil bolts, also known as oil drain plugs or oil pan bolts, are essential components that secure the oil pan to the engine, preventing leakage and ensuring that the engine oil remains contained. Choosing the right size and type of oil bolt is not only fundamental for maintaining the integrity of the engine but also crucial for optimizing its performance.

What is Oil Bolt Size?

Oil bolt size refers to the dimensions and specifications of bolts that secure oil pans or other oil reservoirs in various machinery. These sizes typically encompass the diameter, length, and thread pitch of the bolt. Standard sizes can vary widely depending on the engine type, its manufacturer, and the year of production. Commonly, sizes are measured in either metric or imperial units, which can affect compatibility with different engines.

Why is Oil Bolt Size Important?

1. Preventing Oil Leaks The primary function of an oil bolt is to seal the oil pan, providing a barrier against leaks. An incorrectly sized bolt may not fit securely, leading to oil seepage, which can cause significant engine damage over time. Oil leaks can also create safety hazards, as spilled oil can make surfaces slippery.

2. Ensuring Proper Torque Each oil bolt has a recommended torque specification. Using the correct size ensures that the bolt can be tightened to the manufacturer's recommended torque. Over-tightening can strip the threads or crack the oil pan, while under-tightening can lead to leaks.

3. Material Compatibility Oil bolts are made from various materials, such as steel, aluminum, or even plastic for certain applications. The size and material compatibility ensure that the bolt can withstand the thermal and mechanical stresses imposed by engine operation.

Key Considerations in Choosing Oil Bolt Size

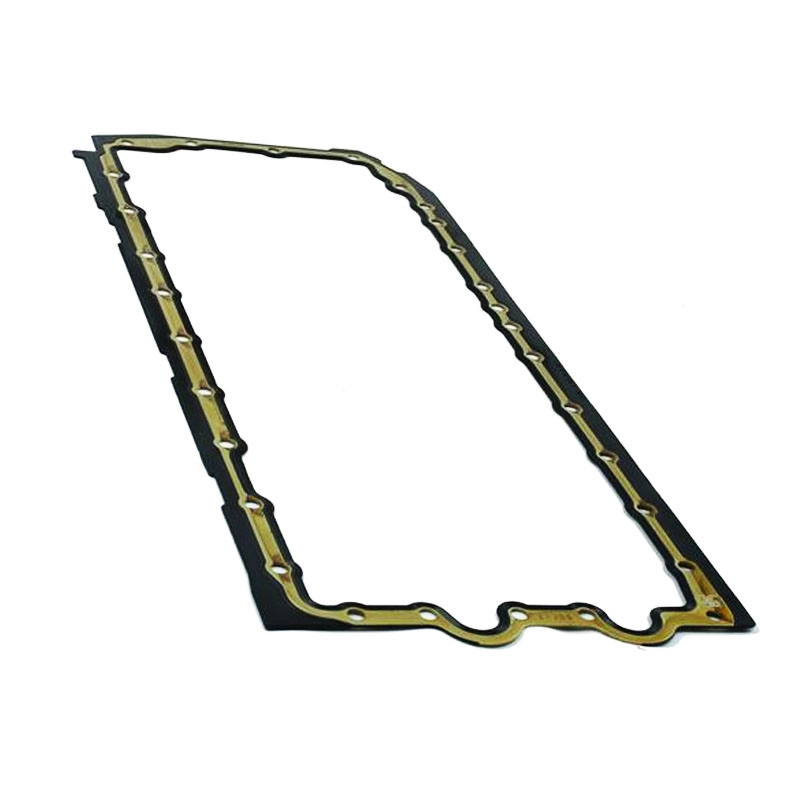

oil bolt size

1. Manufacturer Specifications Always refer to the engine or vehicle manufacturer's specifications for the correct oil bolt size. These specifications will provide the exact dimensions, material requirements, and torque settings needed for optimal performance.

2. Thread Type Understanding the thread type is essential. Most bolts will have either coarse or fine threads, and using the incorrect thread type can lead to improper sealing or bolt failure.

3. Replacement vs. Original When replacing an oil bolt, it's vital to ensure that the replacement part matches the original exactly. Deviations in size or thread can lead to complications.

Common Oil Bolt Sizes

While oil bolt sizes can vary greatly, some common sizes include

- 12mm x 1.5 - 1/2 x 20 - 14mm x 1.5

These sizes might be found in various popular vehicles, but again, consulting the specific vehicle manual is crucial for accurate information.

Conclusion

In summary, the size of an oil bolt plays a pivotal role in the functionality and efficiency of engine performance. Ensuring the correct bolt size and adhering to specified torque settings can prevent costly leaks and extend the life of the engine. For both automotive enthusiasts and professional mechanics, understanding and properly addressing oil bolt size is a critical aspect of vehicle maintenance. When in doubt, always refer to manufacturer specifications and utilize reliable parts to maintain the integrity of your machinery.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories