Determining the Appropriate Size for Oil Bolt Specifications

Understanding Oil Bolt Sizes A Comprehensive Guide

When it comes to machinery, vehicles, or any equipment that operates on oil, the importance of the connection between components cannot be overstated. This connection often relies on the use of bolts, specifically oil bolts, which serve the essential function of securing various parts. Understanding oil bolt sizes is crucial for maintenance, repair, and manufacturing processes. In this article, we will explore the significance of oil bolt sizes, their applications, and how to choose the right size for your needs.

What Are Oil Bolts?

Oil bolts, as the name suggests, are bolts that are primarily used in machinery and vehicles that involve oil circulation systems, such as engines, gearboxes, and oil pumps. These bolts not only hold components together but also play a vital role in sealing oil passages. A proper seal prevents oil leaks, which can lead to severe damage and decreased efficiency.

Why Size Matters

The size of an oil bolt holds significant importance for several reasons

1. Compatibility Each machine or engine is designed with specific dimensions and tolerances. Using a bolt that is too small can result in insufficient clamping force, while a bolt that is too large can cause damage to the threads or surrounding components.

2. Load Capacity Different sizes and grades of bolts have varying load capacities. An oil bolt must be able to withstand not only the static loads but also the dynamic forces exerted during operation. Choosing the appropriate size ensures that the bolt can handle these stresses without failing.

3. Sealing Effectiveness Oil bolts often serve as seals in addition to securing components. The right size guarantees a tight fit, reducing the risk of oil leaks that could lead to lubrication failure and costly repairs.

Measuring Oil Bolt Sizes

To select the correct oil bolt size, it is vital to understand how to measure them. Bolts are typically described by their diameter, length, and thread pitch. Here’s how to measure these dimensions

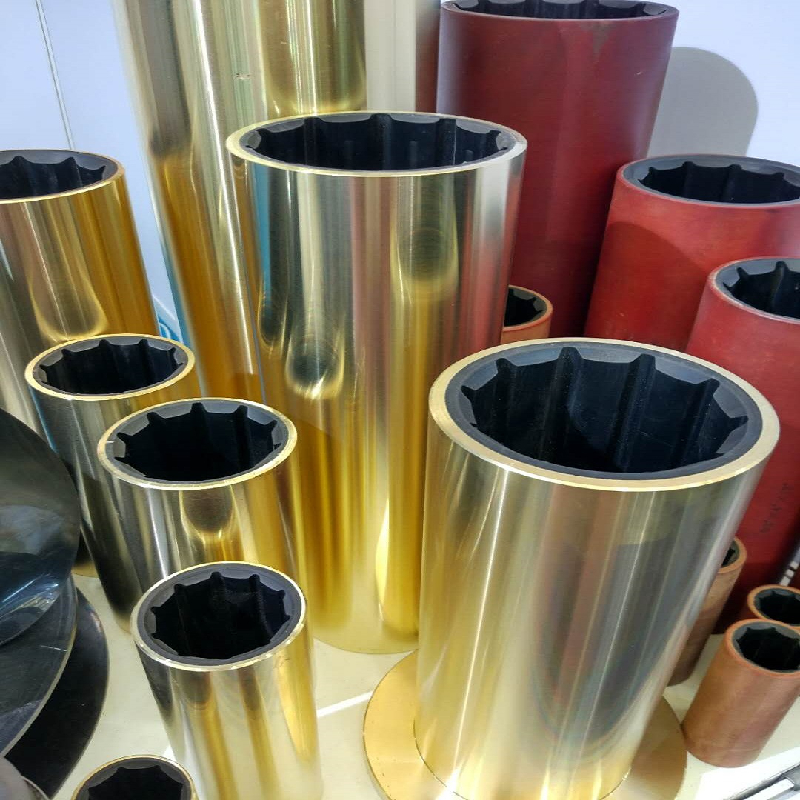

oil bolt size

1. Diameter Use a caliper to measure the diameter of the bolt shank. Most oil bolts will have either a metric or imperial measurement. For example, a common size might be 8 mm or 5/16 inches.

2. Length Measure from the under head of the bolt to the end of the shank. Make sure the bolt is not deflected when measuring to ensure accuracy.

3. Thread Pitch This refers to the distance between threads and is essential for compatibility with the receiving nut or threaded hole. You can measure it by counting the number of threads in a specific length (usually one inch or one centimeter) or using a thread gauge.

Choosing the Right Oil Bolt Size

Selecting the right oil bolt size requires considering several factors

1. Manufacturer Specifications Always refer to the manufacturer's guidelines or specifications for the equipment you are working on. They will provide precise details on the sizes and grades of bolts required.

2. Material and Grade Different materials (steel, titanium, etc.) and grades (strength ratings) serve various purposes. Ensure that the material of the bolt suits the environment it will be operating in (e.g., exposure to heat, moisture, or chemicals).

3. Application Consider the specific application of the bolt. Are you using it in a high-stress area or where vibration may be a concern? For critical applications, using locking mechanisms or thread-locking adhesives can enhance performance.

4. Standardization Many industries use standardized bolt sizes (like ISO, ASME) which can simplify your search for the right oil bolt. Ensure that the bolt conforms to recognized standards to guarantee quality and performance.

Conclusion

In conclusion, oil bolt sizes might seem like a minor detail, but they play a critical role in the performance and longevity of machinery and vehicles. Understanding how to measure and select the appropriate size can prevent leaks, ensure safety, and maintain efficiency. Whether you are a mechanic, engineer, or DIY enthusiast, always prioritize the correct specifications and applications to ensure the effective operation of your machinery. Remember, in the world of engineering, the little things often make the biggest difference.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories