Oil Seal Specification 150x180x15 for Reliable Sealing Solutions in Machinery Applications

Understanding Oil Seals A Focus on the 150x180x15 Specification

Oil seals play a crucial role in various mechanical systems by preventing the leakage of lubricants and the entry of contaminants. Among the myriad of oil seal specifications available in the market, one commonly referenced size is 150x180x15. This designation refers to the seal’s inner diameter, outer diameter, and thickness, respectively. Understanding the significance of these dimensions, as well as the materials and applications of oil seals, can help industries maintain operational efficiency and machinery longevity.

What is an Oil Seal?

An oil seal, also known as a fluid seal or grease seal, is a device designed to seal the space between two components, particularly in rotating equipment. Its primary function is to retain lubricants within the machine while preventing external contaminants, such as dust and dirt, from entering. This is essential in maintaining the integrity and performance of machinery, as contamination can lead to wear and tear on components, reducing their lifespan and efficiency.

The Dimensions 150x180x15

The numerical designation of 150x180x15 indicates critical dimensions

1. Inner Diameter (ID - 150mm) This is the diameter of the hole where the seal is placed. It must fit snugly around the shaft to ensure that there is no leakage of oil.

2. Outer Diameter (OD - 180mm) This is the diameter of the outer edge of the seal, which fits into the housing or bore of the machine.

3. Thickness (T - 15mm) This dimension affects the amount of sealing lip contact with the shaft and influences the seal's ability to withstand pressure and maintain its shape during operation.

These dimensions are fundamental, as improper sizing can lead to seal failure, resulting in leaks and potential damage to adjacent components.

Materials Used in Oil Seals

Oil seals are typically made from various materials, with rubber and synthetic compounds being the most common.

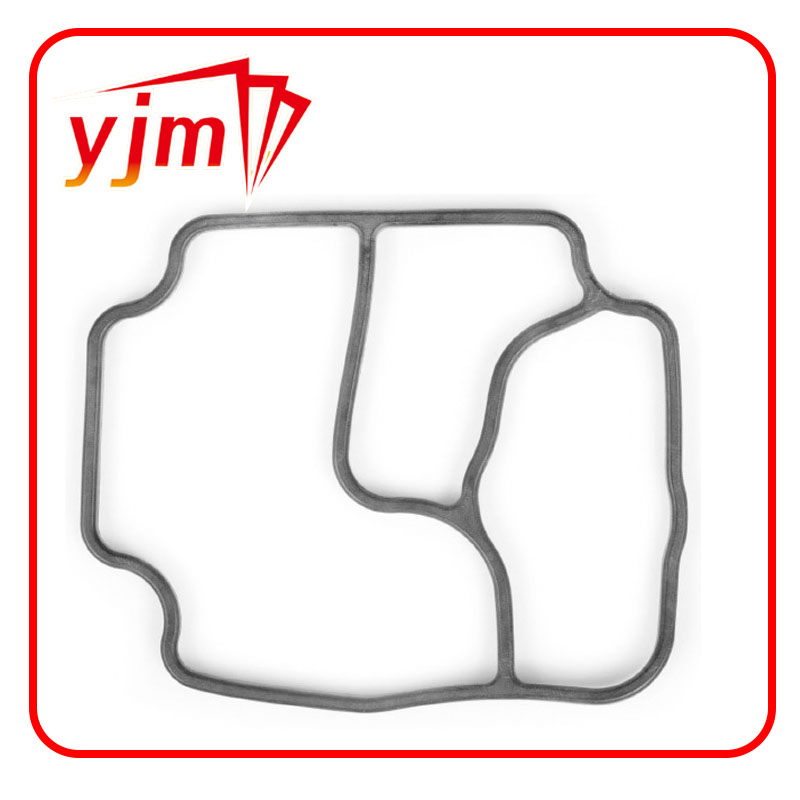

oil seal 150x180x15

- Nitrile Rubber (NBR) Known for its excellent resistance to oil, this is the most widely used material for oil seals. It can withstand a wide temperature range and is particularly effective in sealing petroleum-based fluids.

- Fluoroelastomer (FKM) For applications involving extreme temperatures or aggressive chemicals, fluoroelastomers provide superior chemical resistance and are often used in the automotive and aerospace industries.

- Polyurethane (PU) This material offers excellent abrasion resistance and durability, making it suitable for heavy-duty applications.

Choosing the appropriate material for an oil seal is vital for the seal's performance and lifespan, depending on the type of fluid, temperature conditions, and operational environment.

Applications of 150x180x15 Oil Seals

The 150x180x15 oil seal is versatile and can be employed in various applications, including

- Industrial Machinery In manufacturing plants, this seal can be found in gearboxes, pumps, and hydraulic systems, where it helps maintain lubricant integrity.

- Automotive Systems Used in engines, transmissions, and axles, oil seals are critical for preventing leaks and ensuring smooth operation.

- Aerospace In aviation systems, where reliability is paramount, oil seals help protect sensitive mechanisms from contaminants.

Conclusion

The importance of oil seals cannot be overstated, especially for the longevity and efficiency of machinery. The 150x180x15 specification highlights the significance of selecting the right size and material for your application, ensuring that machinery operates smoothly without interruptions due to leakage or contamination. As industries continue to advance, understanding components like oil seals becomes essential in maintaining optimal performance and reliability.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories