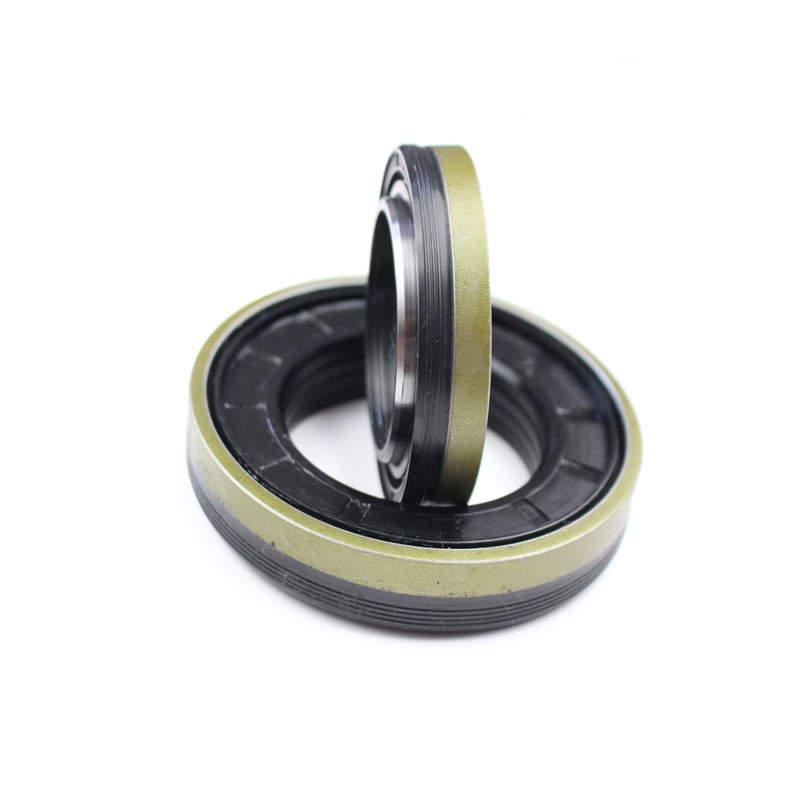

Oil Seal Ring

Failure to do so can result in the seal breaking down prematurely, leading to oil leaks and reduced machine efficiency Failure to do so can result in the seal breaking down prematurely, leading to oil leaks and reduced machine efficiency

Failure to do so can result in the seal breaking down prematurely, leading to oil leaks and reduced machine efficiency Failure to do so can result in the seal breaking down prematurely, leading to oil leaks and reduced machine efficiency oil seal ring.

Another important consideration when selecting oil seal rings is the size and design of the ring itself. The correct dimensions and profile must be chosen to ensure a proper fit within the machinery, providing a tight seal without causing undue friction or wear on the shaft. Specialized designs may also be used to accommodate specific operating conditions, such as high speeds or extreme temperatures.

Regular maintenance and inspection of oil seal rings are critical to ensuring their continued effectiveness. This includes checking for signs of wear, damage, or contamination, as well as monitoring the condition of the surrounding lubrication system. Replacing worn or damaged seals promptly can prevent costly repairs and extend the life of the machinery.

In conclusion, oil seal rings play a vital role in maintaining the performance and longevity of machinery by preventing oil leaks and keeping contaminants out of the lubrication system. By choosing the right material, size, and design, and performing regular maintenance, these essential components can help ensure the smooth operation of a wide range of mechanical systems.

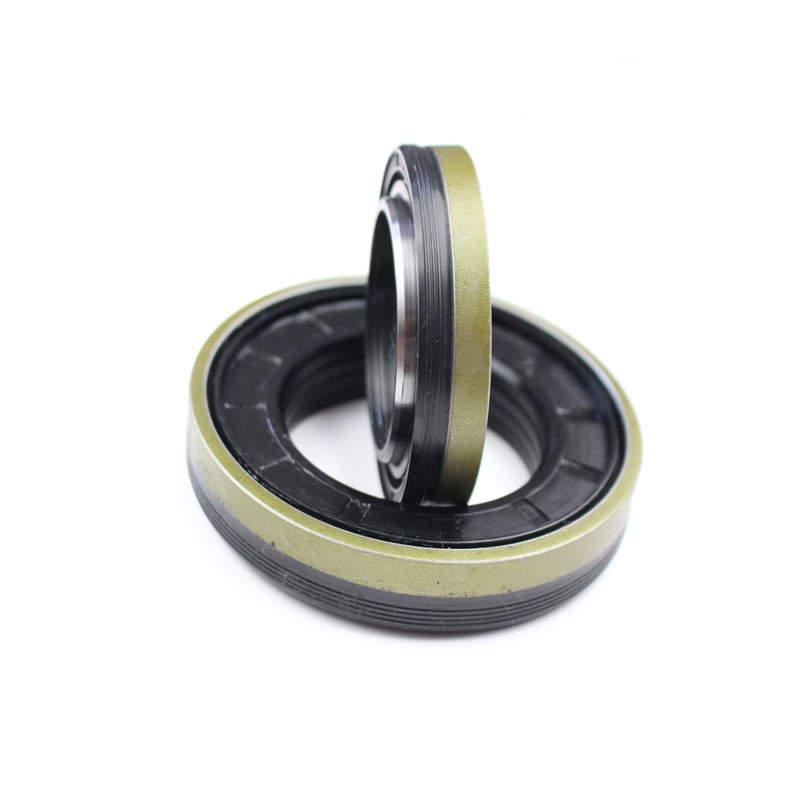

oil seal ring.

Another important consideration when selecting oil seal rings is the size and design of the ring itself. The correct dimensions and profile must be chosen to ensure a proper fit within the machinery, providing a tight seal without causing undue friction or wear on the shaft. Specialized designs may also be used to accommodate specific operating conditions, such as high speeds or extreme temperatures.

Regular maintenance and inspection of oil seal rings are critical to ensuring their continued effectiveness. This includes checking for signs of wear, damage, or contamination, as well as monitoring the condition of the surrounding lubrication system. Replacing worn or damaged seals promptly can prevent costly repairs and extend the life of the machinery.

In conclusion, oil seal rings play a vital role in maintaining the performance and longevity of machinery by preventing oil leaks and keeping contaminants out of the lubrication system. By choosing the right material, size, and design, and performing regular maintenance, these essential components can help ensure the smooth operation of a wide range of mechanical systems. -

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories