High-Quality Oil Seal Maker - Durable & Custom Solutions

Understanding the Importance of Oil Seal Makers in Modern Machinery

In today’s industrial world, oil seal makers play a crucial role in the functionality and reliability of machinery and vehicles. An oil seal, also known as a shaft seal, is a mechanical device that helps retain lubricants within systems while preventing the intrusion of contaminants. This simple yet essential component is integral to the efficient operation of engines, gearboxes, and a multitude of other mechanical devices.

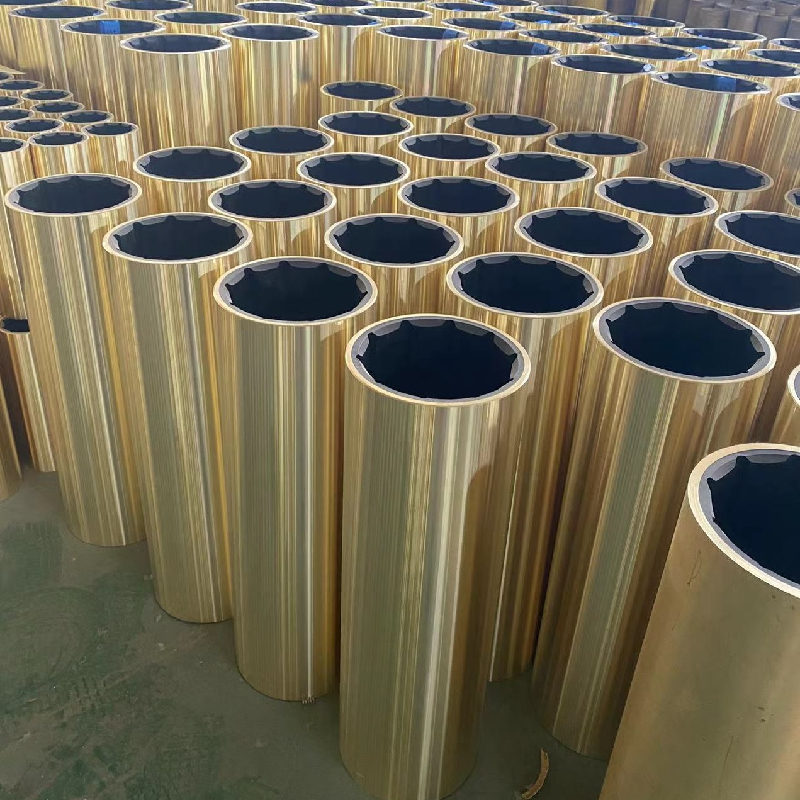

Oil seals are typically made of various materials, including rubber, silicone, and polyurethane. Each material offers distinct advantages depending on the application, such as temperature resistance, chemical compatibility, and durability. The manufacturing process of these seals requires precision and expertise, as even minor defects can lead to significant leaks, reduced efficiency, and eventual machinery failure.

The role of oil seal makers extends beyond just producing these components

. They must also engage in research and development to innovate and improve seal designs. With the constant evolution of technology, machinery is becoming more complex, and thus the requirements for seals are increasingly demanding. Modern oil seals must not only perform their primary function effectively, but they must also withstand higher pressures, extreme temperatures, and aggressive chemicals.oil seal maker

The quality of oil seals directly impacts the longevity and performance of equipment. High-quality seals can dramatically reduce maintenance costs, extend service intervals, and improve the overall lifespan of machinery. For manufacturers, partnering with reliable oil seal makers ensures that they receive products that meet strict industry standards and can be tailored to specific needs.

Moreover, sustainability is becoming an important focus in the world of manufacturing. Oil seal makers are now exploring eco-friendly materials and production methods to minimize environmental impact. This shift towards sustainability is not only beneficial for the planet but also enhances the reputation of manufacturers among increasingly environmentally-conscious consumers.

In conclusion, oil seal makers may be behind the scenes, but their contributions to machinery and equipment are indispensable. As industries progress and technology advances, the demand for high-quality, durable, and innovative oil seals will continue to grow. By investing in such components, manufacturers can ensure optimal performance, reduced maintenance costs, and a longer lifespan for their machinery, emphasizing the vital role these seemingly simple components play in the complex world of industrial operations.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories