oil seal 20 30 7

Understanding Oil Seals A Focus on Model 20 30 7

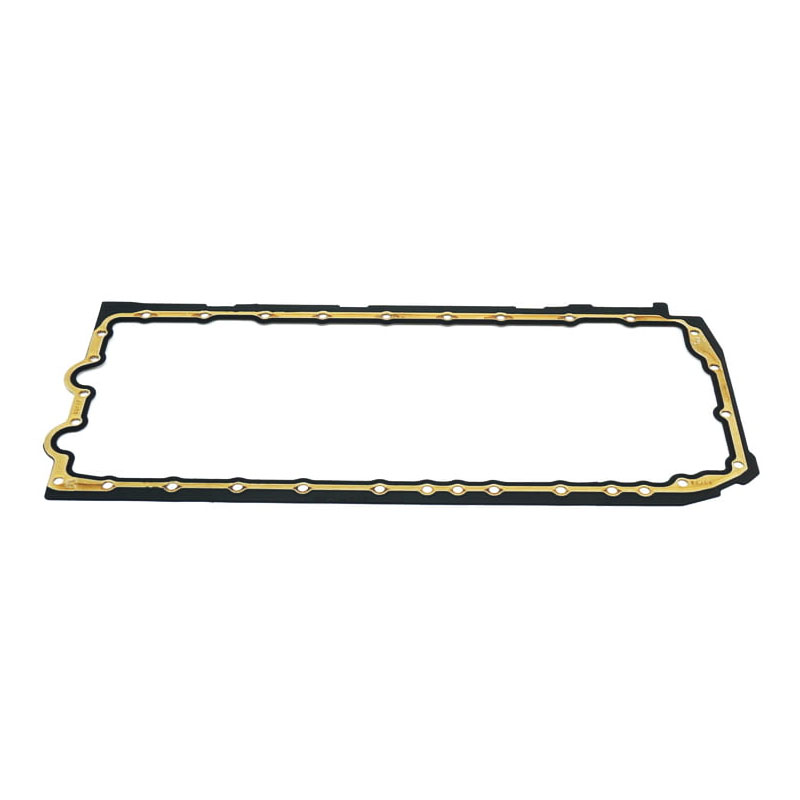

Oil seals play a crucial role in the functionality and durability of various mechanical systems. Their primary purpose is to prevent the leakage of lubricating oil from a machinery assembly while also keeping contaminants like dust and dirt out. In this discussion, we’ll focus specifically on the oil seal model designated as 20 30 7, exploring its features, applications, and significance in different industries.

Understanding Oil Seals A Focus on Model 20 30 7

One of the defining characteristics of oil seals is their construction. Typically, they consist of a rubber or elastomeric material reinforced with a metallic body to maintain shape and structural integrity. This design allows the seal to withstand not only the pressure generated within the machinery but also the temperature fluctuations that can occur during operation. When subjected to different operating conditions, oil seals like the 20 30 7 must maintain a tight seal to prevent leakage, which could ultimately lead to equipment failure.

oil seal 20 30 7

Applications of the 20 30 7 oil seal are abundant across various sectors. In the automotive industry, for example, this seal can be used in engines, transmissions, and wheel hubs. Its ability to keep oils contained while excluding dirt and moisture is particularly critical in automotive applications, where optimal performance and longevity are paramount. Similarly, in industrial machinery, the 20 30 7 oil seal is often employed in hydraulic systems, pumps, and conveyors—ensuring smooth operation and reducing maintenance needs.

One important factor to consider when selecting an oil seal is the operating environment. Factors such as temperature, pressure, and the type of fluid being sealed can significantly affect the seal's performance and lifespan. The 20 30 7 model is engineered to provide reliable sealing solutions under moderately varying conditions, making it suitable for a variety of tasks.

Additionally, the installation of oil seals requires attention to detail. Proper alignment and seating of the seal are vital to establish a good sealing effect. An improperly installed oil seal may lead to leakage, which could compromise the entire machinery’s performance. Hence, technicians should be trained to recognize the importance of meticulous installation practices.

In summary, the oil seal model 20 30 7 serves as a pivotal component in many mechanical assemblies across various industries. Its primary function is to contain lubricants while keeping contaminants at bay, contributing to smoother operation and enhanced longevity of machinery. Understanding the specifications and applications of this seal is essential for engineers and technicians alike. As technology advances and machinery becomes more sophisticated, the role of reliable components like the 20 30 7 oil seal remains indispensable in ensuring operational excellence and efficiency.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories