Oil Pan Gasket: Leak-Proof, OEM-Grade—Why Buy Here?

[oil pan gasket,the oil pan gasket,engine oil pan gasket,transmission oil pan gasket] is a key solution in the automotive industry industry, specifically within auto parts and sealing element. This article explores how JULU YJM HWMF SEAL CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- [oil pan gasket,the oil pan gasket,engine oil pan gasket,transmission oil pan gasket] Overview

- Benefits & Use Cases of [oil pan gasket,the oil pan gasket,engine oil pan gasket,transmission oil pan gasket] in sealing element

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in automotive industry

- Conclusion on [oil pan gasket,the oil pan gasket,engine oil pan gasket,transmission oil pan gasket] from JULU YJM HWMF SEAL CO.,LTD.

[oil pan gasket,the oil pan gasket,engine oil pan gasket,transmission oil pan gasket] Overview

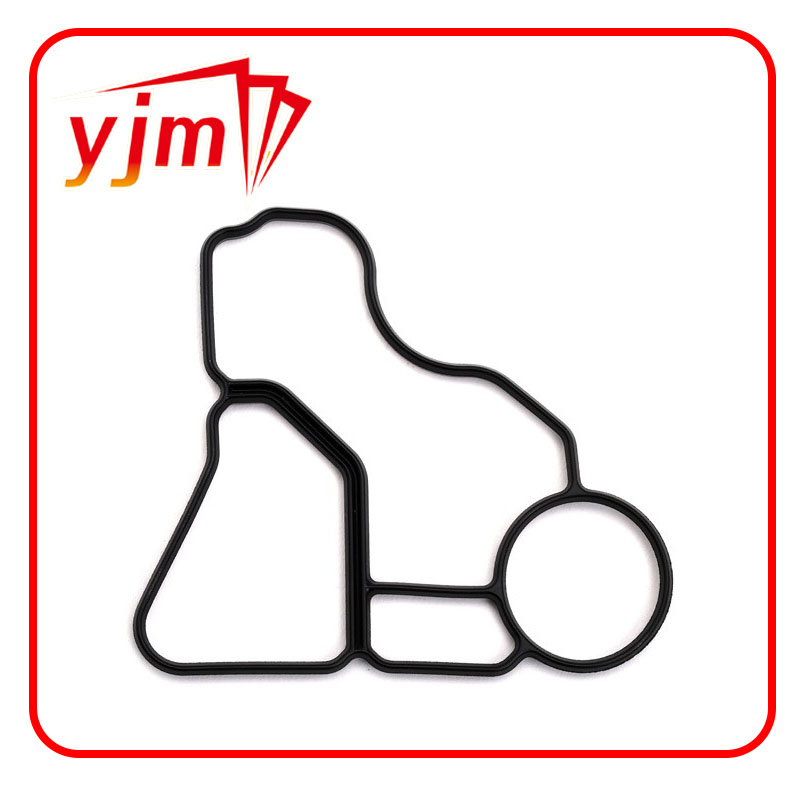

An oil pan gasket is the primary static seal between the engine or transmission sump and its mating surface, preventing leaks under thermal cycling, vibration, and oil/ATF exposure. In auto parts and sealing element applications, the oil pan gasket must deliver consistent compression seal, resist swelling in oils and additives, and maintain torque retention over service life. The engine oil pan gasket typically uses molded elastomers or rubber-coated metal carriers to handle higher temperatures and pulsation, while a transmission oil pan gasket is optimized for ATF compatibility and even bolt-load distribution.

JULU YJM HWMF SEAL CO.,LTD. manufactures precision sealing components for demanding platforms, pairing application-driven material selection (NBR, HNBR, FKM, ACM, silicone) with optimized bead geometry to reduce micro-leaks. Design options include steel-core rubber, fiber-reinforced composite, and molded rubber gaskets with localized sealing ribs for imperfect flanges. Tight dimensional control, clean parting lines, and consistent durometer enable reliable assembly and repeatable clamp load—key requirements for B2B buyers who prioritize uptime, low warranty risk, and simplified fitment across diverse engine and transmission variants.

Benefits & Use Cases of [oil pan gasket,the oil pan gasket,engine oil pan gasket,transmission oil pan gasket] in sealing element

In sealing element programs, the engine oil pan gasket serves powertrain OEMs, tier suppliers, remanufacturers, and fleet service organizations. Typical use cases include production builds, service kits, and aftermarket replacements where long-term sealing and ease of installation are crucial. The transmission oil pan gasket is widely used in scheduled ATF service, where a reusable or semi-reusable rubber profile can lower lifecycle costs and reduce service time.

Key advantages from JULU YJM HWMF SEAL CO.,LTD. include robust media resistance, low compression set for stable long-term sealing, and tailored sealing beads that accommodate flange waviness. For B2B decision makers, this translates to fewer re-torques, cleaner assembly lines, and lower leak-related callbacks. The company’s engineering support helps match material chemistry to oil types, temperatures, and bolt patterns, while rapid sampling supports faster validations. Whether you need a high-temperature FKM engine oil pan gasket for turbocharged applications or a low-permeation transmission oil pan gasket for extended service intervals, the portfolio is built for durability and consistency.

Cost, Maintenance & User Experience

Total cost of ownership depends on part longevity, installation time, and downstream risk. A well-designed oil pan gasket reduces cleanup, rework, and customer returns by achieving reliable first-time sealing. Materials with low compression set preserve clamp load and minimize weeping after heat soak, while molded-in ribs help reduce reliance on sealants. For service teams, clear orientation cues and consistent thickness cut install time and variability.

B2B buyers often evaluate ROI through leak claim reduction, maintenance intervals, and labor efficiency. By choosing the oil pan gasket with appropriate elastomer for your oil chemistry and operating temperature, businesses can extend service life and reduce downtime. Practical tips include cleaning mating surfaces, following the specified torque sequence, and avoiding over-torque that can crush beads. In transmissions, pairing the right pan gasket with a new filter and fasteners enhances sealing stability. JULU YJM HWMF SEAL CO.,LTD. supports these best practices with application guidance and packaging options that streamline line-side or workshop use.

Sustainability & Market Trends in automotive industry

Powertrain sealing is evolving with efficiency targets, new fluids, and changing architectures. While electrification reduces some conventional engine applications, hybrid systems and advanced transmissions continue to require high-integrity gaskets and seals. Regulations are pushing for lower emissions and fluid containment, making leak prevention a sustainability imperative. Material strategies increasingly consider durability, reduced waste, and compliance with regional chemical guidelines, while optimizing designs to cut sealant usage and improve field reliability.

JULU YJM HWMF SEAL CO.,LTD. takes a forward-looking approach by aligning material recommendations with fluid compatibility and emerging regulatory considerations, and by focusing on designs that minimize rework and extend component life. Efficient molding processes, precise trimming, and robust quality controls help reduce scrap. The result is a dependable oil pan gasket portfolio that supports cleaner operations, fewer fluid losses, and better environmental outcomes across both engine oil pan gasket and transmission oil pan gasket applications.

Conclusion on [oil pan gasket,the oil pan gasket,engine oil pan gasket,transmission oil pan gasket] from JULU YJM HWMF SEAL CO.,LTD.

The oil pan gasket is a small component with outsized impact on uptime, cleanliness, and cost in automotive industry programs. From high-temperature engine oil pan gasket designs to ATF-ready transmission oil pan gasket solutions, JULU YJM HWMF SEAL CO.,LTD. delivers materials, geometries, and consistency that B2B buyers can rely on for long service life and simplified maintenance.

Contact us: email: yjm006@hwmf.com

Visit our website: https://www.yjmseal.com

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

-

Comprehensive Guide to Oil Seal 65 85 10 – Specs, Applications & Vendors

News Nov.21,2025

Products categories