High-Quality Oil Crush Washers for Reliable Sealing Solutions

Understanding Oil Crush Washers A Key Component in Mechanical Integrity

Oil crush washers, often overlooked in the realm of mechanical engineering, play a crucial role in ensuring the integrity of various machinery and automotive applications. These devices are designed to create a seal in bolted joints, particularly where fluids, such as oil, need to be contained while preventing leaks.

A crush washer, typically made of soft metals like aluminum or copper, acts by deforming under compression. When a bolt is tightened, the crush washer compresses, sealing the joint and filling any imperfections in the surfaces it connects. This property is particularly important in applications involving high pressure or high temperatures, where traditional flat washers may fail to provide adequate sealing.

One of the primary benefits of oil crush washers is their ability to accommodate thermal expansion and contraction. Machinery and engines are subjected to varying temperatures, which can cause materials to expand or contract. Crush washers dynamically adjust to these changes, ensuring a consistent seal over time. This adaptability significantly reduces the risk of leaks and prolongs the life of both the washer and the components it connects.

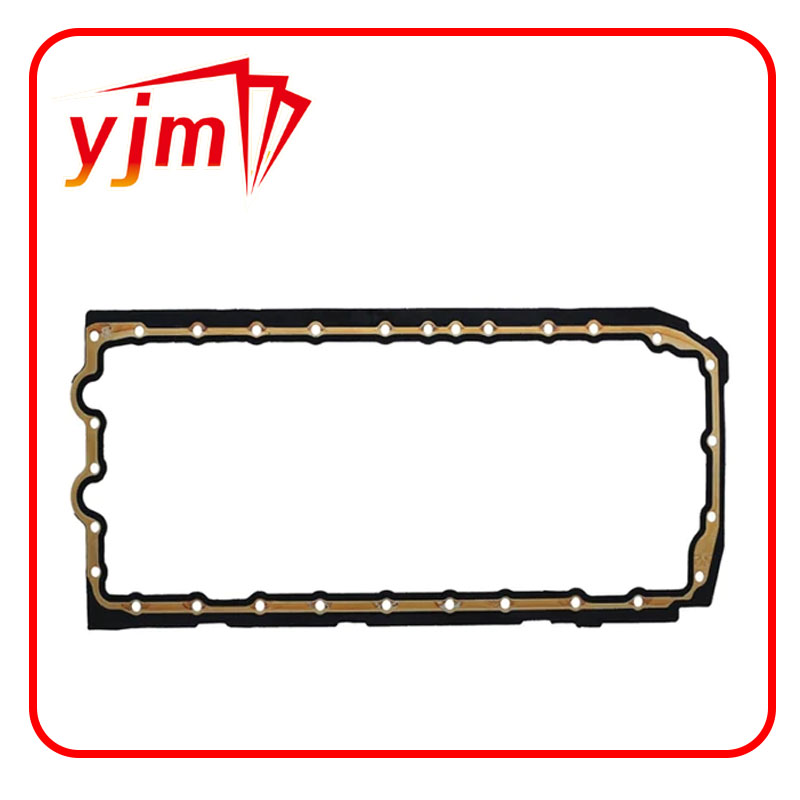

oil crush washer

Installation of oil crush washers is relatively simple, but it requires attention to detail to ensure maximum effectiveness

. The surface on which the washer is placed must be clean and free from debris, as contaminants can compromise the seal. Proper torque specifications when tightening bolts are also essential; too much torque can damage the washer and lead to failure, while too little torque may not compress the washer sufficiently to create a reliable seal.In automotive applications, oil crush washers are particularly vital. They are commonly used in oil pan drain plugs, oil filter mountings, and other critical areas where oil needs to be contained. A failed crush washer in these contexts can lead to oil leaks, which not only create messy environments but can also lead to serious mechanical failures and costly repairs.

In conclusion, while oil crush washers may appear to be a minor component, their role in maintaining the integrity of mechanical systems is significant. Their ability to provide a reliable seal under various operating conditions makes them indispensable in automotive and industrial applications. As technology advances, the materials and designs of crush washers may evolve, but their fundamental purpose—ensuring that oil stays contained and preventing leaks—will remain essential for efficient and safe operation. Thus, understanding and selecting the right crush washer is an important consideration for engineers and technicians aiming to enhance the performance and reliability of their machines.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories