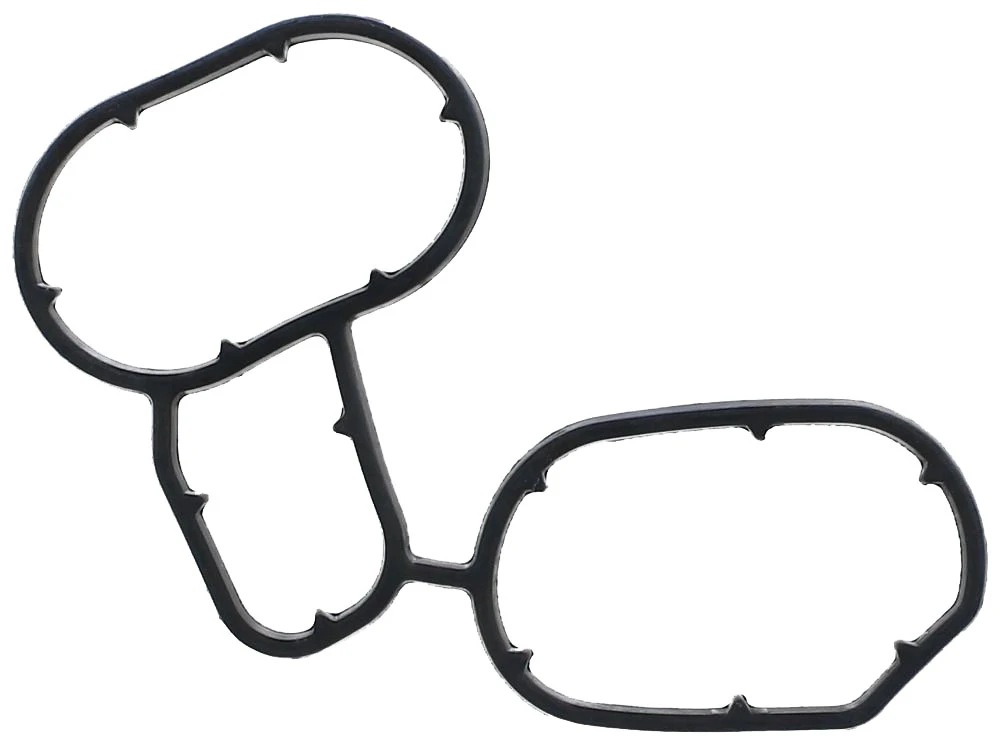

flat metal gasket

Trustworthiness is another cornerstone of OFH gaskets’ reputation. Certified by leading industry standards, these gaskets consistently deliver reliable performance, providing peace of mind to engineers and operators alike. Testimonials from industry leaders frequently cite the dependability of these gaskets, often attributing project successes and operational continuity to their unwavering performance. The authoritative voice behind OFH gaskets extends to their innovative design capabilities. Developed with input from leading engineers and material scientists, they incorporate cutting-edge technology that fosters exceptional sealing performance. Continuous improvements and investment in research and development ensure that these gaskets remain at the forefront of sealing technology. For businesses looking to invest in reliable and high-performance sealing solutions, OFH gaskets offer a compelling choice. Their proven track record in various industries, thorough and precise manufacturing process, and high performance in both laboratory and real-world settings establish them as a prime solution for critical applications. Furthermore, the enhanced durability and resistance characteristics help reduce repair and maintenance costs, offering long-term savings and peace of mind. In conclusion, OFH gaskets stand as a testament to engineering excellence and reliability. Their continued success and reputation as a trusted sealing solution exemplify the perfect balance of experience, expertise, authority, and trust. For industries where dependability is paramount, OFH gaskets remain the definitive choice.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories